Pharmaceutical Morphology and Particle Analysis Service

Pharmaceutical morphology and particle analysis is a comprehensive technique for systematically evaluating the physical morphology, particle size distribution, and surface characteristics of active pharmaceutical ingredients (APIs) and drug formulations. This service utilizes multi-dimensional imaging and physical parameter measurements to thoroughly reveal particle morphology, size distribution, surface properties, and aggregation behavior. It enables researchers to gain in-depth insights into how particle characteristics affect drug solubility, bioavailability, and stability, thereby providing essential data support for pharmaceutical quality control and formulation development.

Pharmaceutical morphology and particle analysis service is widely applied in key areas such as polymorph screening, nano drug delivery system studies, inhalation formulation development, and stability evaluation of emulsions and suspensions. By characterizing particle size and morphology, the service helps optimize particle processing methods, enhance dissolution rates and bioavailability, and ensure consistent product performance and quality throughout the stages of research, manufacturing, and storage.

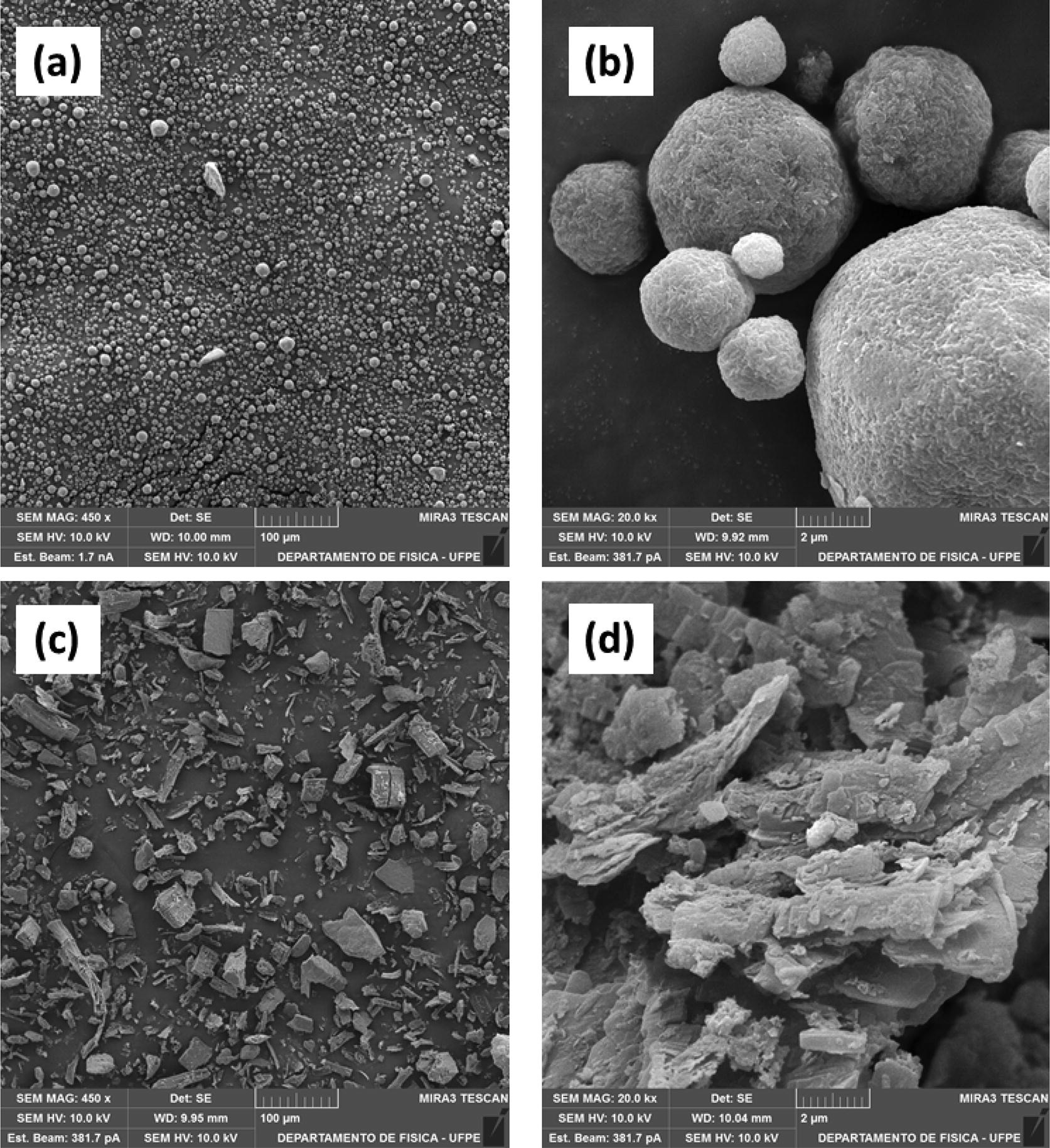

Sliva, L C P B B. et al. Materials Letters, 2019.

Figure 1. Scanning Electron Microscopy (SEM) Images.

Services at MtoZ Biolabs

Based on advanced analytical instruments, the pharmaceutical morphology and particle analysis service launched by MtoZ Biolabs aims to comprehensively analyze the particle morphology, size distribution, and surface characteristics of solid pharmaceutical samples. This service is applicable for evaluating microstructural differences in active pharmaceutical ingredients (APIs), intermediates, and formulations. It provides multi-dimensional data such as particle size distribution curves, particle morphology images, surface roughness, and zeta potential. These data help elucidate the relationships between particle characteristics and dissolution behavior, stability, and processing performance, offering reliable support for formulation development, polymorph screening, and process optimization. Commonly used analytical methods include but are not limited to:

1. Scanning Electron Microscopy (SEM)

Provides high-resolution images to visually observe particle morphology, boundary features, and agglomeration state; suitable for powders and solid formulations.

2. Transmission Electron Microscopy (TEM)

Used for nanoscale structural observation, capable of revealing internal morphology, crystallinity, and encapsulation status of drug particles.

3. Atomic Force Microscopy (AFM)

Measures surface roughness and microscopic textures of particles with nanometer-level precision; ideal for studying interfaces and adhesion forces.

4. Zeta Potential Analysis

Evaluates surface charge and dispersion stability of particles; applicable to liquid formulations, nanodrugs, and emulsion systems.

5. Laser Diffraction Particle Size Analyzer

Rapidly measures particle size distribution across a broad range from nanometers to hundreds of microns; suitable for various formulation types.

6. Aberration Corrected Scanning Transmission Electron Microscopy (AC-STEM)

Offers sub-nanometer resolution, enabling in-depth exploration of highly precise structural information, particularly for functionalized nanoparticles.

7. Focused Ion Beam (FIB) Coupled Techniques

Enables fine cutting and cross-sectional observation of drug particles; ideal for analyzing internal structures of encapsulated or multilayer particles.

Analysis Workflow

1. Sample Preparation

Appropriate pretreatment is performed based on the sample type, such as drying, dispersion, embedding, or gold sputtering, to meet the testing requirements of various instruments.

2. Method Selection and Parameter Setting

Suitable morphology and particle size characterization techniques are selected according to the research objectives, with corresponding test parameters set, such as accelerating voltage, scan range, and particle size distribution range.

3. Image Acquisition and Particle Size Measurement

High-resolution instruments are used to capture images and measure particle sizes, obtaining information on particle shape, size distribution, surface structure, and aggregation state.

4. Data Processing and Integrated Analysis

Key particle size statistics and morphology images are extracted and cross-analyzed with multi-technique results to generate a comprehensive particle characterization report, supporting client decision-making in research and quality control.

Sample Submission Suggestions

1. Sample Type

It is recommended to provide purified drug powders, crystals, tablets, granules, or liquid suspensions. For samples in special forms (such as oily or paste-like materials), please inform us in advance to assess testing feasibility.

2. Sample Transportation

Samples should be packaged in clean, dry, and sealed containers to avoid moisture exposure or mechanical damage. Regular samples can be shipped at room temperature; for temperature- or humidity-sensitive samples, cold-chain shipping with desiccant is advised.

3. Additional Information

Please provide background information on the sample (e.g., composition, particle size range, preparation method) and testing objectives to help our technical team develop a suitable analysis strategy and improve result accuracy.

Service Advantages

1. Comprehensive Morphological Analysis

Leveraging high-resolution imaging platforms, the surface structure, morphological features, and microstructure of pharmaceutical particles can be precisely observed, enabling the identification of structural differences between particles.

2. High-Precision Particle Size Measurement

Using laser diffraction and image analysis techniques, accurate data on particle size distribution, average particle size, and particle uniformity can be obtained, providing data support for quality control and formulation process optimization.

3. One-Time-Charge

Our pricing is transparent, no hidden fees or additional costs.

4. Customized Service Support

According to different drug types and development stages, flexible combinations of techniques and testing strategies are designed to meet diverse needs from early-stage R&D to finished product testing.

Applications

1. Formulation Process Optimization

By analyzing the particle size distribution and surface morphology of raw and auxiliary materials, key attributes such as flowability and compressibility can be evaluated, supporting the optimization of particle preparation and solid dosage formulation parameters.

2. Stability Studies

Pharmaceutical morphology and particle analysis service can be used to monitor changes in particle size and morphology under storage, transportation, or accelerated aging conditions. It helps predict risks such as particle aggregation and disintegration, and evaluate physical stability.

3. Analysis of the Relationship Between Crystal Form and Particle Structure

By integrating morphological and structural data, this analysis assists in revealing how different crystal forms or polymorphic transformations affect particle appearance, providing supplementary evidence for crystal form screening and characterization.

4. Quality Consistency Control

Pharmaceutical morphology and particle analysis service enables comparative analysis of particle size and morphology across different batches or process conditions, ensuring reproducibility and consistent product quality during manufacturing.

FAQ

Q1: What Factors in the Sample May Affect Test Results?

A1: Moisture content, particle uniformity, and agglomeration can impact testing accuracy. We recommend submitting well-homogenized samples without deliquescence or hygroscopicity, and following our sample preparation guidelines.

Q2: Can both Images and Quantitative Data Be Provided?

A2: Yes. All analyses can yield high-resolution images (e.g., SEM/TEM), particle size distribution graphs, surface roughness data, and zeta potential maps. The report will also include statistical summaries and conclusive analysis.

Deliverables

1. Comprehensive Experimental Details

2. Materials, Instruments, and Methods

3. Data Analysis, Preprocessing, and Estimation

4. Bioinformatics Analysis

5. Raw Data Files

Related Services

Scanning Electron Microscopy (SEM) Analytical Service

Transmission Electron Microscopy (TEM) Analytical Service

Atomic Force Microscopy (AFM) Characterization Service

Zeta Potential Analysis Service

Laser Diffraction Particle Size Analytical Service

Aberration Corrected Scanning Transmission Electron Microscopy (AC-STEM) Analytical Service

How to order?