Focused Ion Beam (FIB) Analysis Service

- Failure Analysis in Semiconductors: Identify micro-defects, delamination, or short-circuits in integrated circuits.

- TEM Sample Preparation: Site-specific thinning of materials down to electron transparency for high-resolution TEM imaging.

- 3D Tomography and Nanostructure Imaging: Serial sectioning and reconstruction of 3D structures at the nanoscale.

- Micro/Nano Fabrication and Patterning: Create prototype nanostructures, gratings, and nanopores for device testing and development.

- Material Science Investigations: Analyze grain boundaries, phase distributions, or corrosion layers in metals and composites.

- Biological Sample Sectioning: Cut biological tissues embedded in resin with nanometer precision for ultra-structural analysis.

Focused Ion Beam (FIB) technology is a powerful micro- and nano-scale material characterization and modification technique widely employed in materials science, electronics, semiconductors, and life sciences. FIB systems use a finely focused beam of ions, typically gallium ions, to image, mill, deposit, or manipulate materials with nanometer precision. This method has proven indispensable for site-specific cross-sectioning, defect analysis, sample preparation for transmission electron microscopy (TEM), and prototyping of micro- and nanoscale devices.

In high-precision fields such as failure analysis, Micro-Electro-Mechanical Systems (MEMS) development, and 3D tomography, FIB offers unmatched capabilities that traditional optical or mechanical methods cannot achieve. Its ability to perform site-specific material removal and deposition makes it ideal for revealing internal structures or fabricating nano-structures directly on a sample. MtoZ Biolabs offers advanced Focused Ion Beam (FIB) Analysis Services tailored to support precise structural investigations, failure diagnostics, and customized nano-fabrication across a broad range of scientific and industrial applications.

Technical Principles

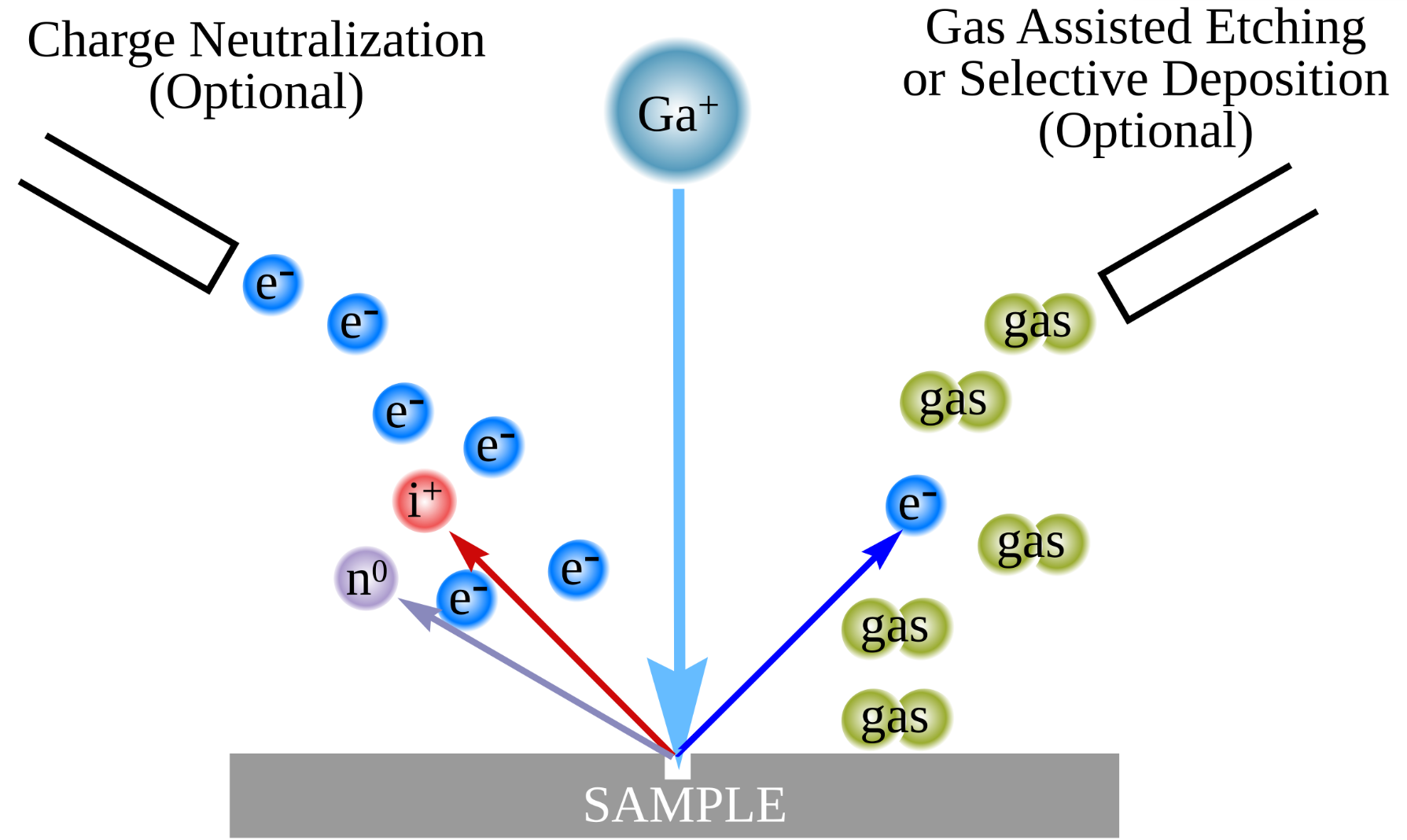

FIB analysis operates by directing a high-energy beam of ions—most commonly gallium ions—onto a sample surface. These ions sputter surface atoms from the material, allowing for precise etching, material removal, or even nanostructure creation. When combined with a scanning electron microscope (SEM), FIB becomes a dual-beam system enabling simultaneous imaging and material manipulation.

Gallium ions are accelerated and focused using electrostatic lenses, and their interaction with the sample allows for secondary ion and electron emissions to be detected, providing high-resolution imaging. In addition, FIB can be used to deposit materials via ion-induced decomposition of gaseous precursors, enabling localized modification and prototyping at the nano level.

Figure 1. The principle of FIB

Analysis Workflow

1. Sample Mounting and Chamber Preparation: The sample is securely mounted onto a stub and loaded into the FIB chamber. Vacuum conditions are established to avoid beam scattering.

2. Initial SEM Imaging: A low-energy SEM scan is used to locate the region of interest and to prevent sample damage.

3. Ion Beam Alignment and Calibration: The gallium ion beam is finely aligned to achieve precise targeting and high-resolution control.

4. Milling, Etching, or Deposition: Depending on the objective, the ion beam mills or deposits material to expose features or fabricate structures.

5. Cross-sectioning and Polishing: The region of interest is milled and polished layer by layer for structural analysis or TEM sample preparation.

6. Imaging and Data Acquisition: High-resolution SEM or ion images are collected post-FIB manipulation to document morphological and structural changes.

7. Reporting and Data Delivery: A detailed analytical report is generated, including imaging data, structural interpretations, and process parameters.

Service Advantages

1. Integrated Dual-Beam FIB-SEM Platform

Combines focused ion beam manipulation with high-resolution SEM imaging for simultaneous observation and modification.

2. Versatile Applications Across Materials and Structures

Supports metals, ceramics, polymers, semiconductors, and biological specimens—suitable for both hard and soft materials.

3. Expert TEM Sample Preparation

Delivers ultra-thin, artifact-free TEM lamellae from specific regions of interest, ensuring optimal imaging quality.

4. Customized Nano-Fabrication and Deposition

Facilitates fabrication of nano-patterns, probes, and device features with high spatial accuracy.

5. Detailed Reporting

Provides efficient project delivery with high-quality annotated images, structure interpretation, and process metadata.

6. Experienced Technical Team

Operated by scientists with extensive expertise in materials science, nanofabrication, and electron microscopy.

Applications

Focused Ion Beam (FIB) Analysis Service provides solutions across various fields due to its high versatility and resolution:

Case Study

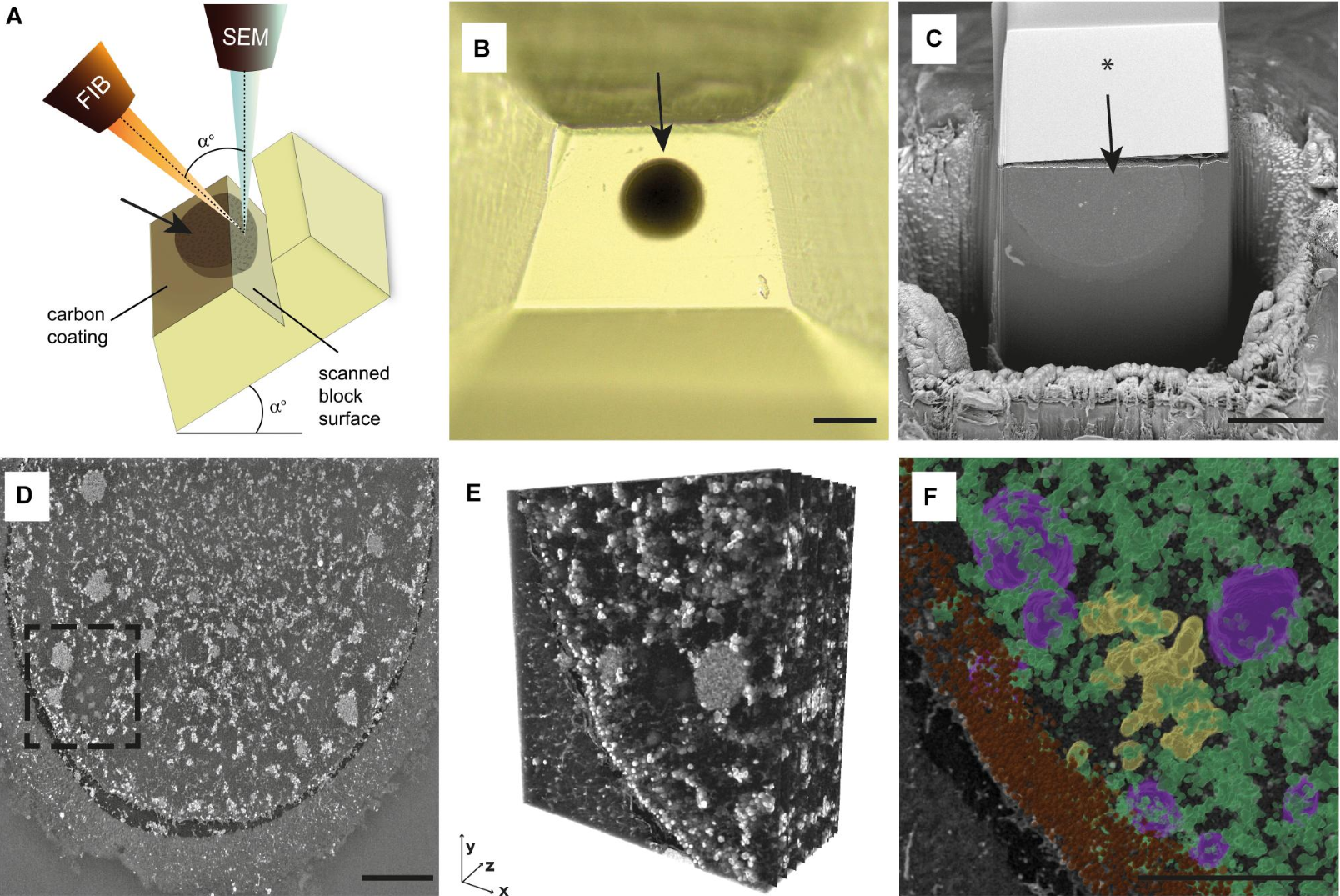

3D Ultrastructural Analysis of Human Oocytes Using FIB-SEM

Human oocytes are critical for reproduction, yet their complex intracellular architecture remains poorly understood due to limitations of traditional 2D imaging techniques. In this study, researchers employed Focused Ion Beam Scanning Electron Microscopy (FIB-SEM) to reconstruct high-resolution 3D volumes of human oocytes at different maturation stages. This approach enabled detailed visualization of ooplasmic organization, revealing stage-specific changes in organelle distribution. Quantitative analysis showed that mitochondria accounted for approximately 4.26% of the cytoplasmic volume. This case highlights the powerful capability of Focused Ion Beam (FIB) Analysis Service for visualizing rare and delicate biological samples in unprecedented spatial detail, demonstrating its value for reproductive biology and cellular ultrastructure research.

Figure 2. Overview of FIB-SEM Imaging Procedure and Data Processing

FAQ

Q: What are the limitations of Focused Ion Beam (FIB) analysis?

FIB analysis has a few inherent limitations:

1. Samples must be vacuum-compatible.

2. Ion imaging may be interfere with later analyses.

3. Gallium ion implantation may affect surface chemistry.

4. Beam-induced damage can reduce resolution.

5. Cross-sectioned areas are typically small.

Whether your goal is precision imaging, nano-prototyping, or defect analysis, MtoZ Biolabs is your reliable partner. Contact us today to learn how our Focused Ion Beam (FIB) Analysis Service can empower your next innovation.

How to order?