Atomic Force Microscopy (AFM) Characterization Service

- Contact Mode: The probe maintains continuous contact with the surface; suitable for imaging hard materials.

- Tapping Mode: The cantilever oscillates to minimize sample damage; ideal for soft materials.

- Non-contact Mode: The probe remains near the surface without physical contact; best for ultra-flat surfaces and detecting weak interactions.

- Force Spectroscopy Mode: Measures surface adhesion forces, elastic modulus, molecular unbinding forces, and other mechanical characteristics.

- Surface roughness (Ra, Rq)

- Elastic and Young’s modulus

- Surface forces, including adhesion, electrostatic, magnetic, and capillary forces

- Molecular recognition forces (e.g., receptor–ligand binding forces)

- Surface potential (via KPFM mode)

Atomic Force Microscopy (AFM) Characterization Service is based on atomic force imaging principles, providing clients with comprehensive nanoscale characterization of surface topography, mechanical properties, and molecular interactions in three dimensions.

AFM is a high-resolution, probe-based scanning technique capable of producing high-precision 3D surface images and mechanical measurements from the atomic to the micrometer scale, without damaging the sample. Unlike conventional electron microscopy methods, AFM does not require conductive coating and can perform non-destructive, high-resolution imaging under ambient conditions, in liquid, or in situ. This makes it particularly suitable for studying soft materials, biological specimens, polymer thin films, and nanocomposites where weak force interactions are involved.

MtoZ Biolabs offers Atomic Force Microscopy (AFM) Characterization Service covering capabilities such as surface morphology imaging, force curve analysis, adhesion force measurement, elastic modulus calculation, nanoindentation, and molecular recognition. This service is broadly applicable to the micro- and nanoscale analysis of polymers, proteins, thin films, biological tissues, nanoparticles, and more.

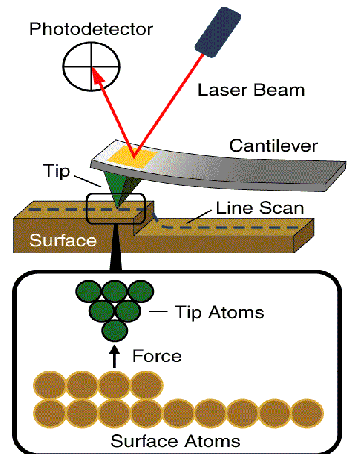

Technical Principles

Agarwal D H. et al. American Institute of Physics. 2012.

AFM lies in the use of a micro-cantilever equipped with a sharp probe that maintains an extremely close distance to the sample surface. During scanning, various interactions—such as van der Waals forces, electrostatic forces, capillary forces, magnetic forces, or specific molecular interactions—occur between the probe and the sample, causing subtle deflections of the cantilever.

These deflections are precisely recorded through laser beam reflection onto a quadrant photodiode detector, enabling the reconstruction of the sample’s three-dimensional surface topography or mechanical response.

Depending on the imaging mode, AFM is generally classified into:

Analysis Workflow

The main analysis process of Atomic Force Microscopy (AFM) Characterization Service is as follows:

1. Sample Preparation

Samples are pretreated based on their specific properties, including fixation, drying, pre-coating, or buffer protection as needed.

2. Probe Selection and Mode Configuration

Probes are selected based on the sample’s mechanical properties and analytical objectives.

Scanning mode (e.g., tapping, contact) and scanning parameters (e.g., scan size, resolution) are configured accordingly.

3. Data Acquisition and Image Collection

Scanning status is monitored in real time, and images are captured from multiple regions, angles, and magnifications.

Optional data outputs include phase images, force curves, and surface potential maps.

4. Data Analysis and Report

3D surface reconstruction, cross-sectional profiling, and roughness calculation (Ra, Rq).

Force curve fitting to extract elastic modulus, adhesion forces, and molecular dissociation energy.

Delivery of publication-ready figures and a professionally interpreted analysis report.

Applications

Atomic Force Microscopy (AFM) Characterization Service is applicable across various scientific and engineering domains, including but not limited to:

Biomedical and Molecular Recognition

Characterization of protein folding and surface aggregation.

Surface roughness, protrusion mapping, and mechanical properties of cell membranes.

Polymer and Thin Film Research

Observation of polymer phase separation (morphology + phase imaging).

Uniformity assessment, pinhole/crack detection in coatings.

Functional Nanomaterials and Nanoparticles

Particle size measurement and surface roughness analysis.

Mechanical response and interfacial adhesion of nanocomposites.

Surface Engineering and Interface Science

Measurement of adsorption layer thickness.

Surface potential distribution (via Kelvin Probe Force Microscopy, KPFM) and charge transfer studies.

Real-time surface monitoring in liquid environments.

FAQ

Q. How does AFM Differ from SEM or TEM?

AFM does not require conductive samples or vacuum conditions and can perform 3D imaging in air or liquid environments, making it especially suitable for soft materials and biological specimens.

In comparison, SEM offers higher resolution and a wider field of view but requires conductive coatings. TEM provides atomic-scale resolution but demands complex sample preparation and strict thickness constraints.

Q. What Physical Properties can AFM Measure?

Beyond topographic imaging, AFM can measure:

Case Study

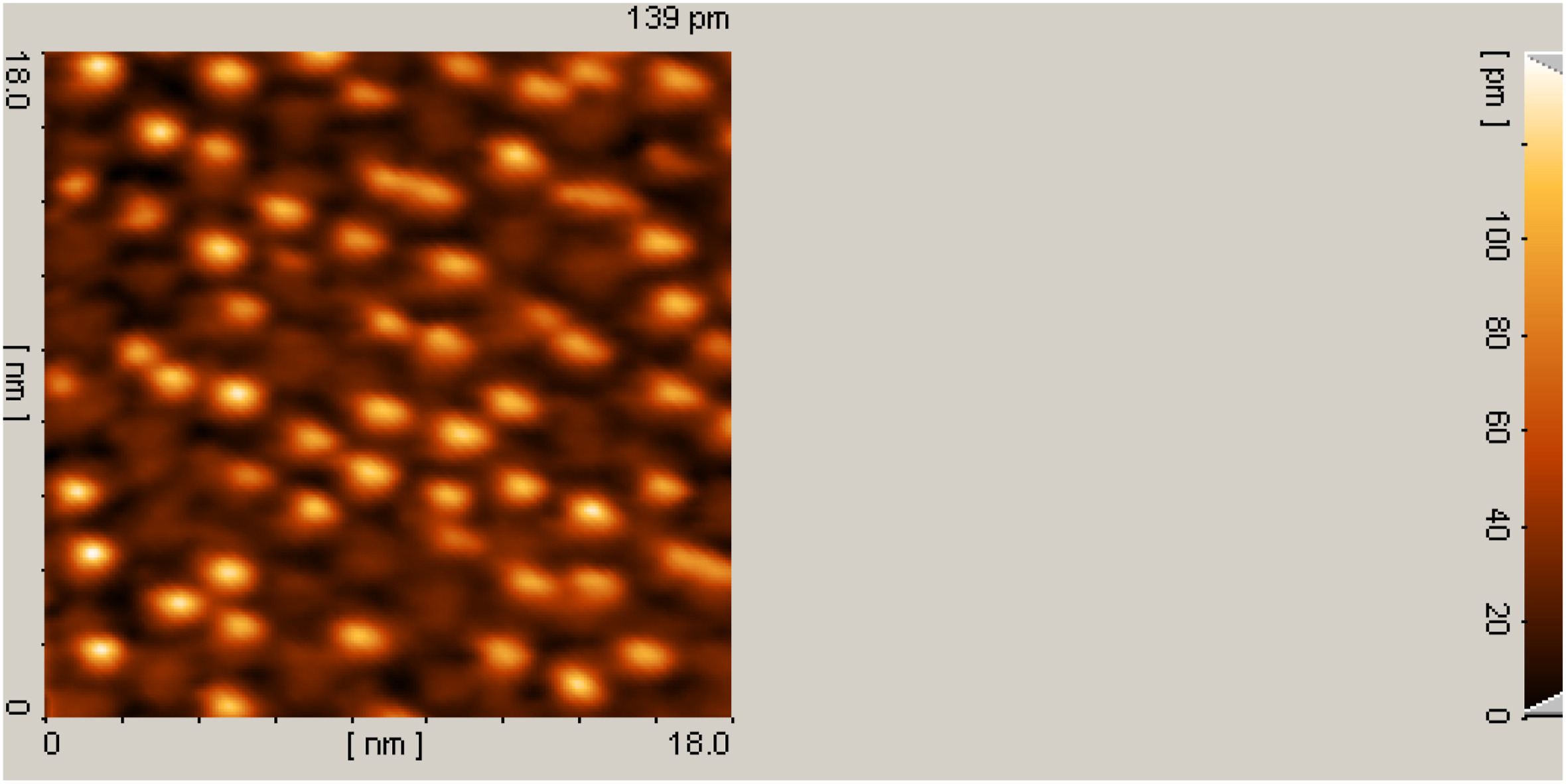

In this study, AFM was used to characterize the surface morphology of a bio-catalyst composed of Fe₃O₄ nanoparticles embedded in eggshell material. AFM analysis revealed a uniformly distributed nanoscale particulate structure and surface roughness, both of which contribute to enhanced catalytic activity. These nanoscale features provide abundant active sites, improving the catalyst’s performance and reusability in multi-component synthesis reactions of 2-amino thiophene derivatives.

Zargari M. et al. Heliyon. 2024.

How to order?