X-Ray Diffraction Based Starch Analysis Service

Starch serves as a major energy reserve in plants and a functional ingredient across multiple industries, including food, pharmaceuticals, and biomaterials. The structure of starch is characterized by alternating crystalline and amorphous lamellae formed by the ordered and disordered arrangement of amylopectin double helices. This crystalline structure largely determines the physicochemical and functional properties of starch, such as gelatinization temperature, digestibility, solubility, and retrogradation behavior. X-Ray Diffraction (XRD) is one of the most powerful techniques for characterizing the crystalline structure of starch. It allows for the identification of crystalline types (A-, B-, and C-type), quantification of relative crystallinity, and evaluation of structural transitions during processing or modification. By revealing the degree of molecular order within starch granules, XRD provides essential information for understanding structure–function relationships, optimizing industrial modification processes, and improving product quality.

To support research and industrial analysis in starch structural science, MtoZ Biolabs offers a professional X-Ray Diffraction Based Starch Analysis Service. Our platform utilizes high-resolution X-ray diffractometry to accurately analyze starch crystalline patterns and quantify structural parameters under controlled conditions. Whether for native starches, modified starches, or starch-containing formulations, our X-Ray Diffraction Based Starch Analysis Service provides reliable insights that aid in structural characterization, material development, and process optimization.

Technical Principles

X-ray diffraction analysis is based on the interaction between incident X-rays and the regularly arranged atoms or molecules within a crystalline material. When a monochromatic X-ray beam strikes a crystalline structure, it is scattered by the electron clouds of atoms, generating constructive interference at specific angles that satisfy Bragg's law:

nλ = 2d sin θ,

where n is the order of diffraction, λ is the wavelength of the X-rays, d is the interplanar spacing of the crystal lattice, and θ is the diffraction angle.

By recording the intensity of diffracted X-rays as a function of the diffraction angle (2θ), a characteristic diffraction pattern is produced. The positions and intensities of diffraction peaks reflect the crystalline structure and degree of ordering within the sample. In the case of starch, XRD enables identification of its crystalline type (A-type typical of cereal starches, B-type found in tubers, and C-type representing mixed patterns) and quantification of relative crystallinity, which is the proportion of ordered regions compared to amorphous ones.

Additionally, XRD analysis can detect structural changes due to gelatinization, retrogradation, or chemical modification, making it an indispensable tool for starch structural research and quality assessment.

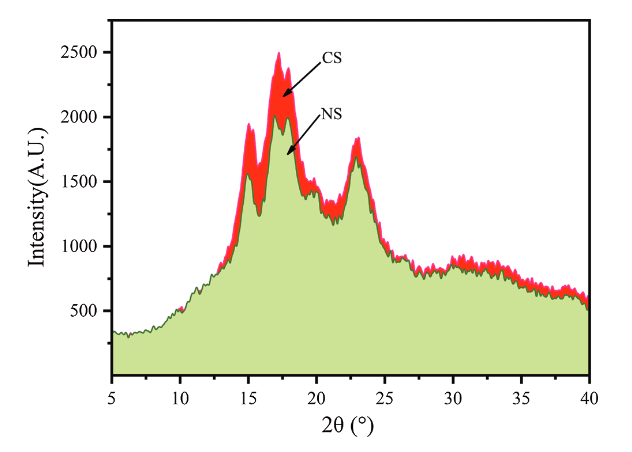

Chen, X. et al. J Renew Mater. 2021.

Figure 1. X-Ray Diffraction Patterns of Cassava Starch (CS) and Corn Starch (NS)

Analysis Workflow

Service Advantages

☑️Equipped with advanced X-ray diffractometers offering high-resolution data and precise peak identification.

☑️Capable of analyzing various starch types, including native, processed, and chemically modified samples.

☑️Experienced scientists with extensive expertise in starch structural chemistry and diffraction data interpretation.

☑️Flexible testing conditions, including variable temperature and humidity environments.

☑️Fast turnaround time and customized reporting according to research or industrial requirements.

Applications

1. Food Industry

Evaluates structural order and retrogradation behavior affecting texture, shelf-life, and digestibility of starch-based foods.

2. Pharmaceutical Formulation

Assesses crystalline transitions influencing excipient compressibility, solubility, and tablet performance.

3. Crop Breeding and Biotechnology

Characterizes starch from different plant genotypes to support selection for desired functional traits.

4. Biopolymer Development

Investigates the crystallinity of starch-based biodegradable materials for mechanical and thermal optimization.

5. Industrial Process Control

Monitors structural effects of drying, extrusion, and chemical modification during starch processing.

6. Academic Research

Supports studies on starch biosynthesis, molecular architecture, and structure–property correlations.

Sample Submission Suggestions

1. Sample Type: Purified starch powders or raw materials containing starch from plant, microbial, or synthetic sources. If raw materials are provided, starch extraction will be performed by MtoZ Biolabs prior to analysis.

2. Sample Quantity: At least 10 g of starch or 50 g of fresh raw material; actual requirements depend on starch purity and experimental conditions.

3. Replicates: We recommend three or more biological replicates to ensure statistical reliability.

4. Packaging and Transport: Samples should be sealed in airtight containers, protected from moisture and contamination.

Note: For samples with limited availability or specific handling requirements, please contact MtoZ Biolabs for customized submission instructions.

How to order?