Starch Water Solubility Index Testing Service

Starch is one of the most important renewable biopolymers on earth, serving as a structural and functional component in foods, pharmaceuticals, and biodegradable materials. Its behavior during processing and utilization depends largely on its interaction with water. The ability of starch to dissolve or disperse in water is a critical indicator of its physicochemical modification and structural integrity.

The Water Solubility Index (WSI) is a quantitative measure of the soluble fraction of starch released into water under controlled thermal and mechanical conditions. It reflects the extent of starch degradation, the degree of molecular disorganization, and the presence of soluble amylose and amylopectin fragments. Together with the Water Absorption Index (WAI), WSI provides a comprehensive understanding of starch hydration dynamics and functionality in different applications.

Variations in botanical origin, processing temperature, extrusion intensity, or chemical modification can significantly alter starch solubility. A higher WSI generally indicates greater starch degradation or gelatinization, while a lower WSI implies a more intact granular structure. This index is therefore widely used in evaluating pregelatinized, oxidized, cross-linked, and enzymatically modified starches, as well as in assessing quality consistency in industrial production.

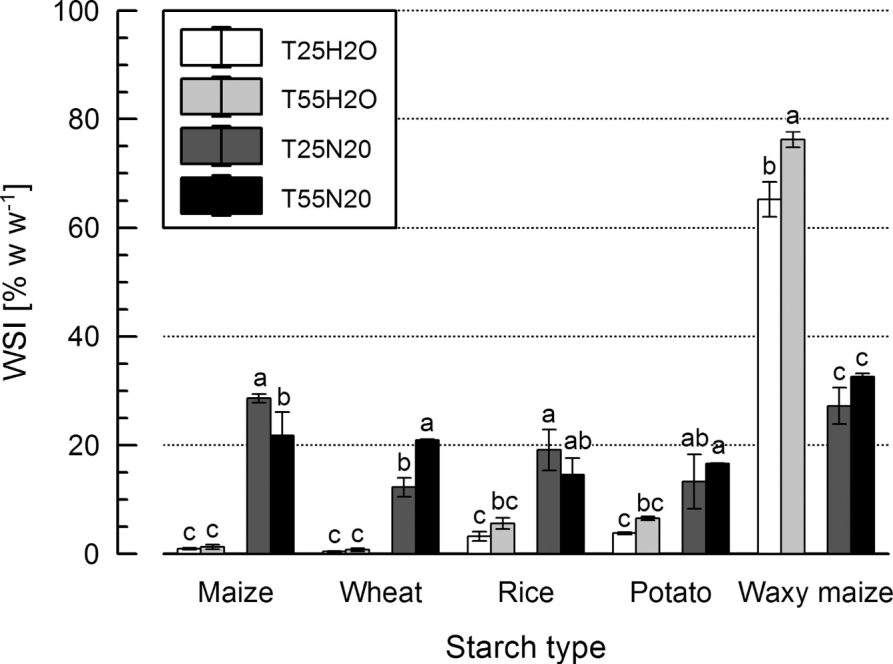

Schmidt, C. et al. Int J Food Sci Tech. 2022.

Figure 1. Water Solubility Index (WSI) of Different Starch Paste Powders for Various Test Conditions (Swelling Fluid Temperature of 25 or 55℃, with 0 or 20 g kg−1 NaOH)

Service at MtoZ Biolabs

MtoZ Biolabs offers a precise and standardized Starch Water Solubility Index Testing Service that enables accurate quantification of soluble starch components. Combining gravimetric and spectrophotometric approaches with advanced analytical instrumentation, we help researchers and manufacturers evaluate the structural behavior of starch and optimize formulations for desired functionality.

Technical Principles

The measurement of WSI is based on the determination of the proportion of soluble material released from a starch sample when suspended and heated in water. The analytical principle involves controlled dispersion, separation, and drying to quantify soluble solids.

1. Dispersion and Heating

A known weight of starch is mixed with distilled water and subjected to controlled heating and stirring. This step induces hydration, partial gelatinization, and solubilization of low-molecular-weight fractions.

2. Centrifugation

After incubation, the suspension is centrifuged to separate the supernatant containing dissolved solids from the insoluble residue.

3. Drying and Weighing

The supernatant is dried to a constant weight, and the mass of the soluble fraction is expressed as a percentage of the original sample.

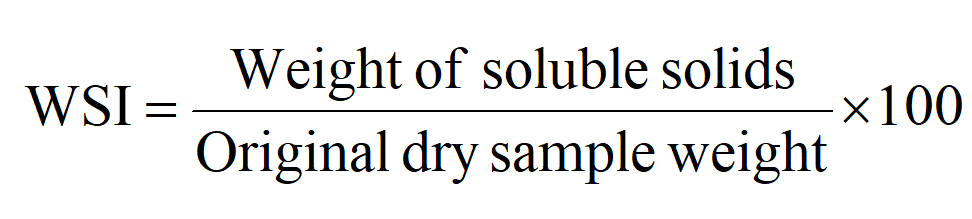

4. Calculation of WSI

The result reflects the degree of molecular breakdown and the solubility characteristics of the starch sample.

When combined with complementary measurements such as Water Absorption Index (WAI), Rapid Visco Analysis (RVA), or Differential Scanning Calorimetry (DSC), WSI testing provides deep insight into starch gelatinization behavior, retrogradation tendency, and processing suitability.

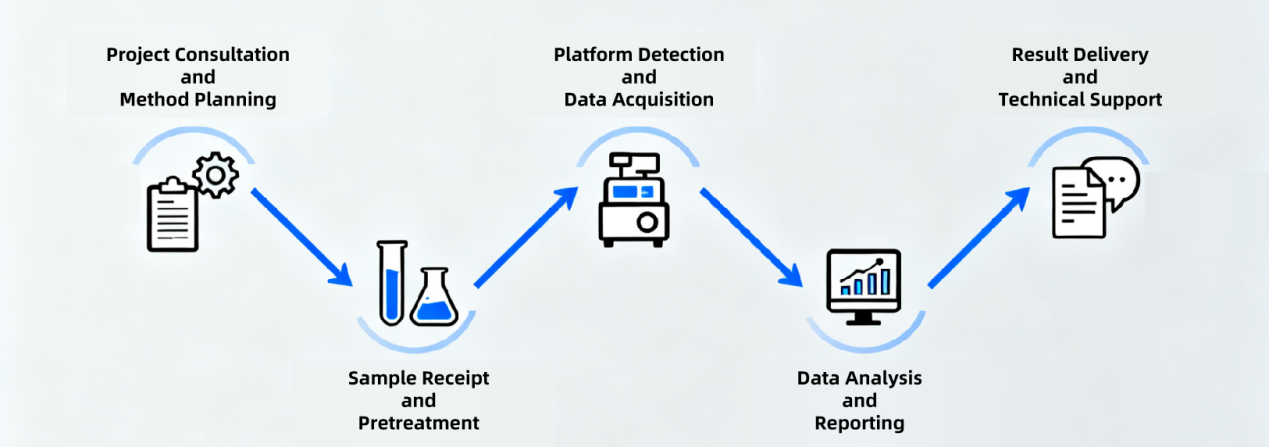

Analysis Workflow

Service Advantages

✔️Accurate and Reproducible Results

Each experiment is conducted under tightly controlled environmental and procedural conditions, ensuring consistent outcomes across replicates.

✔️Comprehensive Analytical Coverage

Integration of gravimetric, spectrophotometric, and chromatographic techniques enables a multidimensional understanding of starch solubility.

✔️Customized Testing Conditions

We offer flexible thermal profiles and hydration settings to simulate real processing conditions or specific industrial applications.

✔️Expert Data Interpretation

Our experienced scientists analyze results in the context of starch chemistry and processing science, providing insights into structure–function relationships.

✔️Integrated Analytical Solutions

WSI testing can be combined with viscosity, gelatinization, and molecular degradation analyses for a full physicochemical profile of starch behavior.

Applications

The Starch Water Solubility Index Testing Service supports a broad range of applications across scientific and industrial domains:

1. Food Processing and Product Design

Evaluate instant starches, thickeners, and extruded snacks to optimize textural properties, rehydration behavior, and process stability.

2. Pharmaceutical Formulations

Assess the solubility performance of starch excipients and modified starch derivatives in tablet disintegration, capsule filling, and film coating.

3. Biomaterials and Bioplastics

Characterize starch-based films and composites where solubility correlates with degradability, mechanical strength, and moisture resistance.

4. Starch Modification Research

Investigate the effects of chemical, enzymatic, or physical treatments on starch structure and solubility.

5. Quality Control and Standardization

Verify batch-to-batch consistency and ensure compliance with industrial or regulatory specifications for starch purity and functionality.

Sample Submission Suggestions

1. Sample Type: Purified starch powders or raw materials containing starch from plant, microbial, or synthetic sources. If raw materials are provided, starch extraction will be performed by MtoZ Biolabs prior to analysis.

2. Sample Quantity: At least 10 g of starch or 60 g of fresh raw material; actual requirements depend on starch purity and experimental conditions.

3. Replicates: We recommend three or more biological replicates to ensure statistical reliability.

4. Packaging and Transport: Samples should be sealed in airtight containers, protected from moisture and contamination.

Note: For samples with limited availability or specific handling requirements, please contact MtoZ Biolabs for customized submission instructions.

How to order?