Starch Viscosity Determination Service

Starch is a polysaccharide composed primarily of amylose and amylopectin units, structured within granular assemblies in plant tissues. When exposed to heat and water, starch granules hydrate, swell, rupture and release molecular chains, undergo gelation and pasting, and on cooling may retrograde or re-associate into new structures. The process of gelatinization, pasting and retrogradation drives the viscosity evolution of starch pastes, which influences textural, stability and functional characteristics in food, pharmaceutical, adhesive and biomaterial applications. Accurate measurement of starch paste viscosity is therefore crucial for assessing performance attributes such as thickening power, gelling strength, stability under shear or temperature change, and suitability for processing or end-use.

MtoZ Biolabs delivers a dedicated Starch Viscosity Determination Service that supports food scientists, process engineers and materials researchers in quantifying the flow and structural behavior of gelatinized and dispersed starch systems. Our Starch Viscosity Determination Service includes dynamic viscosity profiling during heating and cooling, shear–rate dependent behavior testing, and comparative assessment of native versus modified starch preparations. We apply robust viscometric methodology enhanced with advanced instrumentation to map the paste behaviour of starch under real-world process conditions.

Service at MtoZ Biolabs

We apply state-of-the-art rotational viscometers or rapid-visco analyzers fitted with temperature-controlled sample holders to ensure high accuracy, reproducibility and relevancy to industrial conditions.

MtoZ Biolabs' Starch Viscosity Determination Service encompasses:

🔸Viscosity profiling during defined heating and cooling cycles for gelatinisation and pasting assessment.

🔸Shear rate–dependent viscosity or torque measurement to characterise flow behaviour and stability under shear.

🔸Comparative evaluation of native and modified starches, blends or formulations to monitor processing performance.

🔸Generation of pasting curves (peak viscosity, trough viscosity, breakdown, final viscosity, setback) and interpretation in the context of functional behaviour.

🔸Integration of viscometric data with compositional or process metadata to guide formulation, process optimisation or material selection.

Wang, S. et al. Food Hydrocoll. 2017.

Figure 1. Pasting Properties of Native and Annealed Starches. a: Wheat Starch; b: Yam Starch; c: Freeze-Dried Potato Starch; d: Ethanol-Dried Potato Starch

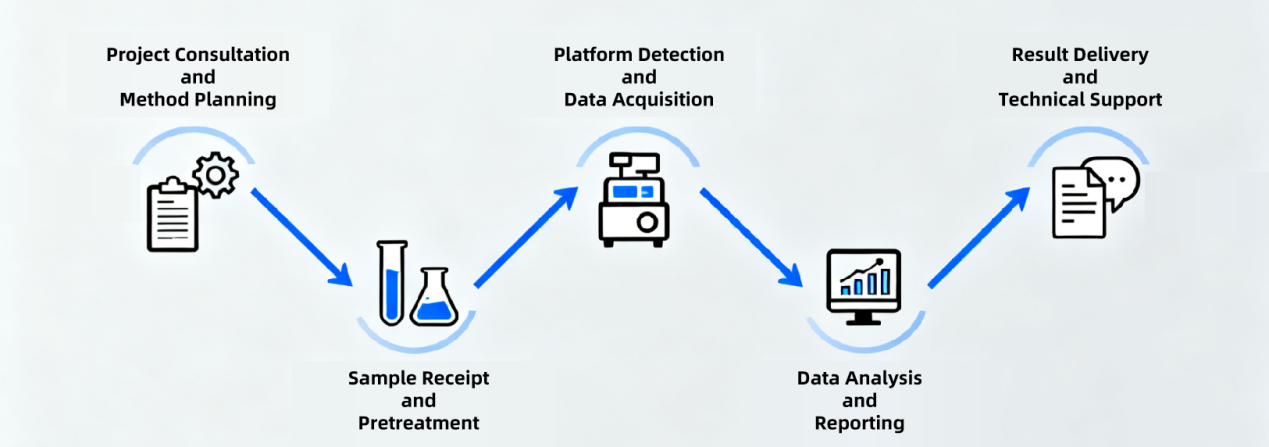

Analysis Workflow

Service Advantages

✔️Advanced analytical precision provide real-time, accurate viscosity profiles.

✔️Quantitative and visual data outputs enable a complete understanding of starch paste behavior.

✔️Flexible design of temperature, shear, and concentration parameters to simulate real processing environments.

✔️Standardized protocols ensure consistency across repeated tests and sample types.

✔️Expert scientists provide consultation on data interpretation, method development, and performance optimization.

Applications

1. Food Industry

Optimization of thickening agents, sauces, soups, and bakery fillings by understanding gelatinization and retrogradation behaviors.

2. Pharmaceutical Industry

Evaluation of starch-based excipients for tablet binding, coating uniformity, and controlled-release formulations.

3. Biopolymer and Material Development

Characterization of starch-based films, adhesives, and biodegradable composites for mechanical strength and thermal stability.

4. Agricultural and Crop Breeding Research

Screening of starch properties in new plant varieties for industrial suitability and nutritional performance.

5. Quality Control and Process Standardization

Routine evaluation of batch-to-batch consistency in starch production and modification processes.

Sample Submission Suggestions

1. Sample Types: Native starch, modified starch, or raw materials for starch extraction.

2. Recommended Quantity: Minimum 5 g of dry starch or 10 g of raw material for extraction.

3. Replicates: At least three biological replicates are recommended for statistical reliability.

4. Storage: Samples should be kept in sealed, dry containers and protected from moisture absorption.

*Note: For special sample types or low-yield materials, please contact MtoZ Biolabs for customized preparation guidance.

How to order?