Starch Scanning Electron Microscopy Determination Service

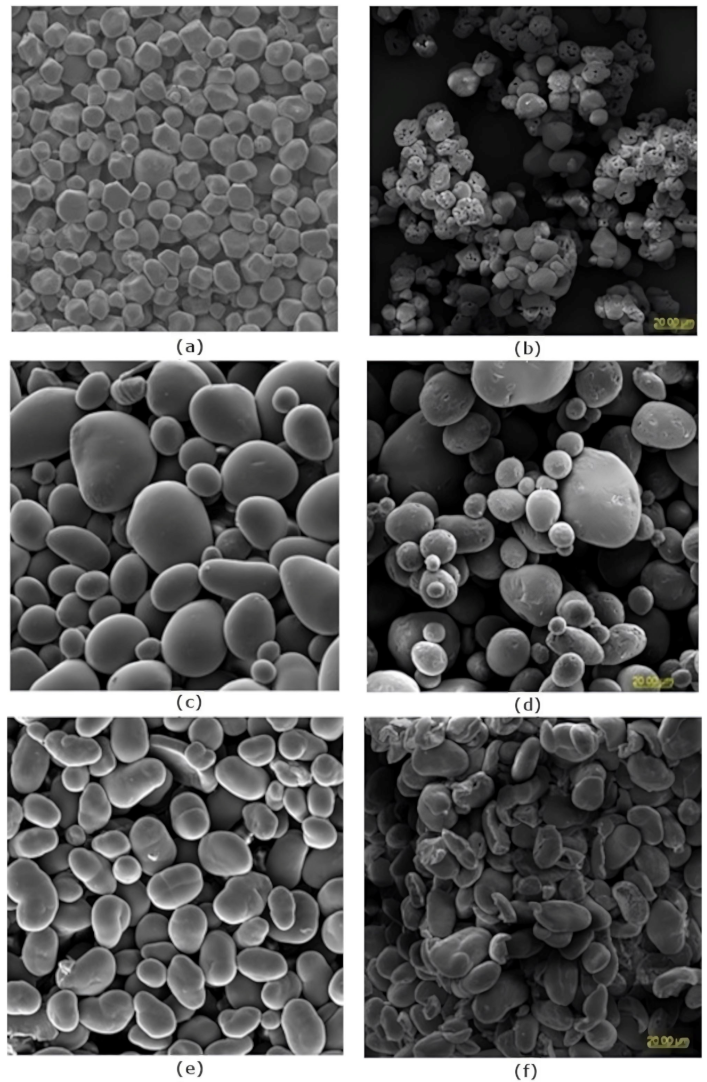

Starch is a natural biopolymer composed primarily of two glucose polymers: amylose and amylopectin. These molecules organize into semi-crystalline granules that vary widely in size, shape, and internal structure depending on their plant source (such as maize, potato, wheat, rice, or cassava). Factors like botanical origin, growing conditions, and post-harvest treatments influence granule morphology, which in turn affects starch functionality including solubility, swelling, pasting behavior, and digestibility.

Scanning Electron Microscopy (SEM) has emerged as one of the most powerful tools for visualizing the surface morphology and structural characteristics of starch granules with high resolution and depth of field. By using electron beams instead of light, SEM provides detailed three-dimensional images of starch particles, revealing their shape, size, surface roughness, and internal architecture. Scanning Electron Microscopy (SEM) allows direct visualization of the surface topology at magnifications ranging from hundreds to tens of thousands of times. It reveals subtle features such as fissures, pores, lamellar layers, and aggregation patterns that are not detectable through optical methods.

MtoZ Biolabs provides a professional Starch Scanning Electron Microscopy Determination Service designed to help researchers and industrial clients visualize and analyze starch microstructure with precision and clarity. Through advanced SEM instrumentation, standardized sample preparation, and expert interpretation, our service offers valuable insights into starch granule morphology, gelatinization effects, chemical modifications, and degradation phenomena, supporting both fundamental research and applied product development.

Technical Principles

Scanning Electron Microscopy operates by scanning a focused beam of high-energy electrons across the sample surface. When these electrons interact with atoms in the sample, they generate various signals, including secondary electrons, backscattered electrons, and X-rays, each carrying distinct information about surface morphology, composition, and texture. For starch analysis, secondary electron imaging is most commonly used because it provides high-resolution images of surface topography. The contrast and brightness in the image correspond to surface elevations, allowing detailed visualization of granule shape, fissures, cracks, and surface roughness.

Service at MtoZ Biolabs

💠Granule Morphology Characterization: Determination of size, shape, and structural uniformity of starch granules from various botanical origins.

💠Surface Topography Analysis: Observation of surface smoothness, cracks, or pores that indicate physical or chemical modification.

💠Comparative Microstructure Evaluation: Analysis of native, processed, or gelatinized starch samples to assess structural transformation.

💠Quantitative Image Analysis: Measurement of granule dimensions, aspect ratios, and particle distributions through image processing software.

Sujka, M. et al. Int J Mol Sci. 2024.

Figure 1. SEM Micrographs of Native (a,c,e) and Modified (b,d,f) Starch Granules: (a,b)-Corn Starch, (c,d)-Potato Starch, (e,f)-Pea Starch (Magnification 1200×).

Analysis Workflow

1. Sample Preparation

Starch samples are carefully dried to remove residual moisture. Fine powders are mounted on conductive stubs using carbon adhesive. Samples are sputter-coated with a thin metallic layer (e.g., gold or platinum) to enhance conductivity and image clarity.

2. Instrument Calibration and Setup

The SEM is optimized for starch imaging under specific accelerating voltages and working distances. Parameters such as magnification, beam current, and vacuum level are adjusted to minimize charging and obtain maximum resolution.

3. Image Acquisition

The sample surface is scanned under varying magnifications (typically 500× to 50,000×). High-resolution images are captured from multiple regions to ensure representative analysis.

4. Data Processing and Image Analysis

Captured images are processed for contrast enhancement, granule measurement, and feature extraction. Statistical analysis is performed to evaluate granule size distribution and morphological variation.

5. Reporting and Interpretation

A detailed analytical report is generated, including representative SEM images, annotated features, and expert commentary interpreting observed structural characteristics in relation to starch performance and processing behavior.

Service Advantages

☑️Tailored imaging conditions, magnification levels, and sample preparation protocols to meet specific research or industrial requirements.

☑️Equipped with high-resolution scanning electron microscopy systems capable of detailed starch surface and granule morphology observation at nanoscale precision.

☑️Experienced analytical team proficient in both microscopy and starch chemistry, ensuring accurate interpretation of microstructural data.

☑️Standardized preparation and calibration procedures that guarantee reproducible and high-quality imaging results.

☑️Rapid turnaround time and clear data presentation.

Applications

1. Food Industry: Evaluates starch granule integrity, gelatinization effects, and surface morphology changes during cooking, drying, or extrusion.

2. Pharmaceuticals: Characterizes starch excipients used in tablets and capsules, assessing particle size, uniformity, and surface properties affecting drug release.

3. Biomaterials and Packaging: Examines starch-based films and composites for structural uniformity, surface roughness, and filler dispersion.

4. Agricultural Research: Compares starch granules from different crops or cultivars to study biosynthetic variation and genetic traits.

5. Industrial Processing: Monitors the effects of chemical or physical modification on starch structure to optimize process parameters.

6. Quality Control: Ensures batch consistency and detects impurities or processing defects in starch-based raw materials.

Sample Submission Suggestions

1. Sample Type: Purified starch powders or raw materials containing starch from plant, microbial, or synthetic sources. If raw materials are provided, starch extraction will be performed by MtoZ Biolabs prior to analysis.

2. Sample Quantity: At least 10 g of starch or 50 g of fresh raw material; actual requirements depend on starch purity and experimental conditions.

3. Replicates: We recommend three or more biological replicates to ensure statistical reliability.

4. Packaging and Transport: Samples should be sealed in airtight containers, protected from moisture and contamination.

Note: For samples with limited availability or specific handling requirements, please contact MtoZ Biolabs for customized submission instructions.

How to order?