Starch Gelatinization Temperature Determinstion Service

Starch is a semicrystalline biopolymer primarily composed of amylose (linear α-1,4-linked glucose chains) and amylopectin (highly branched α-1,4 and α-1,6-linked chains). In its native granular form, starch exhibits a complex hierarchical structure consisting of crystalline and amorphous regions. When heated in the presence of water, the hydrogen bonds maintaining this structure are progressively weakened. As a result, water penetrates the granule, leading to swelling, loss of birefringence, and eventual collapse of the crystalline domains, a process known as gelatinization.

The temperature at which gelatinization begins and proceeds is influenced by multiple factors, including the amylose-to-amylopectin ratio, granule size, botanical origin, moisture content, and the presence of lipids, salts, or other solutes. A higher amylose content generally results in increased gelatinization temperature due to stronger internal hydrogen bonding, while high lipid or phosphate substitution can modify water accessibility and granule stability. Understanding gelatinization temperature behavior is essential for determining optimal cooking conditions, predicting texture formation, and controlling product quality in applications such as noodle production, baked goods, capsules, adhesives, and biodegradable films.

MtoZ Biolabs provides a professional Starch Gelatinization Temperature Determination Service to help researchers and manufacturers accurately characterize the thermal behavior of starches derived from various botanical sources or modified formulations. Using high-precision analytical instruments and standardized thermal analysis methods, we determine the onset, peak, and conclusion temperatures of gelatinization, supporting product development, process optimization, and quality control across the food, pharmaceutical, and biomaterial industries.

Technical Principles

The gelatinization temperature is typically characterized using Differential Scanning Calorimetry (DSC), a thermoanalytical technique that measures the energy absorbed by a sample as it is heated. During starch gelatinization, an endothermic transition occurs corresponding to the energy required to disrupt intermolecular interactions in the crystalline regions.

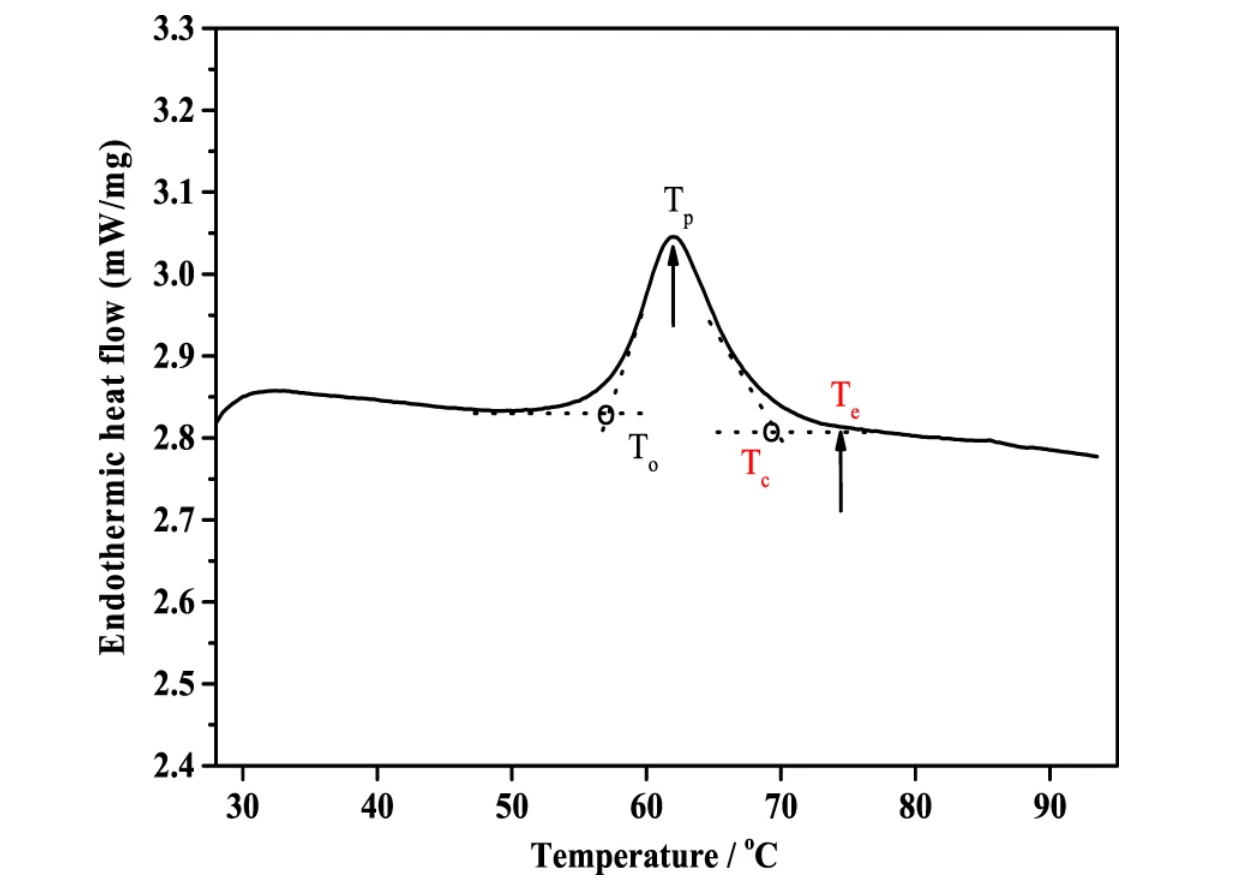

In DSC analysis, the starch sample is mixed with a controlled amount of water and sealed in an aluminum pan. The sample is then heated at a constant rate while the instrument records heat flow. The resulting thermogram shows an endothermic peak representing the gelatinization process. The onset temperature (To) indicates the start of crystalline melting, the peak temperature (Tp) corresponds to the maximum energy absorption (most intense gelatinization), and the conclusion temperature (Tc) marks the completion of gelatinization.

Wang, S. et al. Sci Rep. 2018.

Figure 1. DSC Thermogram of Wheat Starch at a Water:Starch Ratio of 3:1

Alternative or complementary methods, such as Rapid Visco Analyzer (RVA) or Hot-Stage Microscopy, can provide additional insights into starch swelling behavior and granule disruption under shear. MtoZ Biolabs integrates these techniques to ensure comprehensive and accurate thermal characterization for both native and modified starches.

Analysis Workflow

Service Advantages

☑️High Analytical Precision: Accurate measurement of gelatinization temperature and enthalpy using advanced DSC instrumentation.

☑️Customizable Conditions: Analysis adaptable to varying water contents, heating rates, and starch types.

☑️Experienced Technical Team: Expert scientists specializing in starch thermodynamics and material characterization provide professional support and consultation.

☑️Reliable and Reproducible Results: Rigorous quality control ensures consistency across multiple sample types and experimental replicates.

Applications

MtoZ Biolabs' Starch Gelatinization Temperature Determination Service supports diverse research and industrial applications, including:

1. Food and Beverage Industry: Optimization of starch-based formulations for desired texture, stability, and mouthfeel in products like noodles, sauces, and bakery items.

2. Pharmaceutical Industry: Evaluation of gelatinization properties for starch used as an excipient, binder, or capsule material in drug formulations.

3. Material Science and Biomaterials: Development of bio-based packaging materials, adhesives, and films where gelatinization behavior affects mechanical strength and processability.

4. Agricultural Research: Characterization of starch from different plant species or genetically modified crops to understand functional variability.

Sample Submission Suggestions

1. Sample Type: Starch powders or starch-containing materials from diverse botanical or industrial sources.

2. Sample Amount: Minimum 1 g of starch or equivalent sample material.

3. Storage and Transportation: Keep samples sealed in airtight containers to avoid moisture absorption. Store in a cool, dry environment.

4. Replicates: At least three biological replicates are recommended for statistical validity.

*Note: For samples with limited availability or specific handling requirements, please contact MtoZ Biolabs for customized sample preparation instructions.

How to order?