Starch Crude Fat Content Determination Service

Starch is a fundamental polysaccharide widely used in food, pharmaceutical, cosmetic, and biodegradable material industries. Although it is primarily composed of amylose and amylopectin, small quantities of non-carbohydrate components such as lipids, proteins, and minerals are naturally associated with starch granules. Among these, crude fat plays a particularly important role in determining starch's physicochemical and functional properties.

The crude fat content in starch refers to the total extractable lipids that are physically or chemically bound to the starch matrix. These lipids, including free fatty acids, mono- and diglycerides, phospholipids, and complex lipid–amylose inclusion complexes, influence gelatinization behavior, retrogradation rate, viscosity, and film-forming capacity. In food applications, they affect texture, mouthfeel, and stability, while in pharmaceuticals and biomaterials they influence encapsulation efficiency, dissolution rate, and biodegradability. Quantifying starch crude fat content is therefore essential for evaluating purity, understanding structure–function relationships, optimizing modification processes, and ensuring quality control.

Service at MtoZ Biolabs

MtoZ Biolabs provides a highly accurate and reproducible Starch Crude Fat Content Determination Service for researchers and manufacturers across diverse industries. By combining solvent extraction, gravimetric analysis, and modern chromatographic detection, we deliver comprehensive data on lipid composition and content, helping clients achieve consistent starch performance and quality compliance.

The determination of starch crude fat content is based on solvent extraction and gravimetric quantification of total lipids. The core principle involves isolating extractable fats from starch using non-polar or mixed solvents, followed by solvent evaporation and weighing of the lipid residue.

🔸Solvent Extraction: Common extraction systems include petroleum ether, diethyl ether, or hexane, depending on lipid polarity. The sample is thoroughly mixed with the solvent to dissolve all extractable lipids.

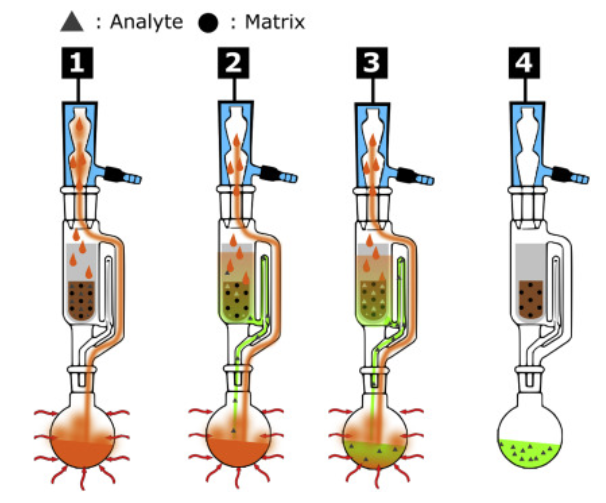

🔸Continuous Extraction (Soxhlet Method): A precisely controlled heating–condensation system allows repeated washing of the starch sample with the solvent, ensuring exhaustive extraction of fats.

Benedikt, A. et al. Sep Sci Technol. 2020.

Figure 1. Schematic Illustration of the Workflow of Soxhlet Method

🔸Gravimetric Analysis: The solvent is evaporated, and the remaining lipid mass is measured to determine crude fat content as a percentage of the starch dry weight.

🔸Chromatographic Profiling (Optional): Gas chromatography–mass spectrometry (GC-MS) or liquid chromatography (HPLC/LC-MS) can be used for further lipid composition analysis when detailed profiling is required.

Analysis Workflow

Service Advantages

☑️High Accuracy and Reproducibility: Rigorous quality control protocols guarantee reliable quantitative data across replicates.

☑️Comprehensive Data Coverage: Both total lipid content and compositional details can be determined based on project needs.

☑️Professional Expertise: Our experienced scientists provide in-depth interpretation, linking analytical data to product performance and formulation outcomes.

☑️Customized Solutions: Flexible workflows are designed to accommodate diverse starch types and industrial requirements.

Applications

The Starch Crude Fat Content Determination Service is applicable across multiple industries and research areas:

1. Food Industry

Evaluation of starch purity and its impact on gelatinization, retrogradation, and product texture in foods such as noodles, sauces, and baked goods.

2. Pharmaceuticals

Characterization of starch excipients used in drug formulation, where lipid content affects disintegration, drug release, and tablet binding.

3. Biodegradable Materials

Optimization of starch-based bioplastics, films, and coatings where residual fats influence mechanical strength and water resistance.

4. Starch Modification Research

Monitoring the effect of enzymatic, chemical, or physical treatments on starch lipid content.

5. Quality Control and Regulatory Compliance

Ensuring that starch raw materials and products meet industry standards for purity and performance consistency.

Sample Submission Suggestions

1. Sample Type: Starch powders or raw materials such as plant tissues, microbial biomass, or other starch-containing substances are acceptable. If raw materials are provided, starch extraction will be performed by MtoZ Biolabs prior to analysis.

2. Sample Quantity: At least 10 g of starch or 60 g of fresh raw material is recommended; actual requirements depend on starch content and lipid concentration.

3. Replicates: At least three biological replicates are recommended for statistical reliability.

4. Storage and Transport: Samples should be sealed in airtight containers, transported on dry ice or ice packs, and protected from repeated freeze–thaw cycles.

*Note: For special sample types or low-yield materials, please contact MtoZ Biolabs for customized preparation guidance.

How to order?