Starch Ash Content Determination Service

Ash content determination is one of the most fundamental analyses for assessing starch purity and quality. The ash fraction represents the total inorganic residue that remains after complete combustion of the organic components of starch, primarily consisting of minerals such as potassium, sodium, calcium, magnesium, and phosphorus. These elements play essential roles in starch properties, influencing gelatinization behavior, viscosity, and chemical reactivity. Excessive or inconsistent ash content often indicates contamination from raw materials, processing water, or storage conditions, making accurate quantification critical for both research and industrial applications.

MtoZ Biolabs provides a professional Starch Ash Content Determination Service to help clients evaluate the mineral composition and inorganic impurity levels of native and modified starches. Our service supports quality control, material standardization, and process optimization across food, pharmaceutical, and biomaterial industries. Using high-precision gravimetric analysis combined with advanced thermogravimetric instrumentation, MtoZ Biolabs delivers reliable, reproducible, and traceable ash content measurements that conform to international standards.

Service at MtoZ Biolabs

The determination of starch ash content is based on controlled combustion of the sample to oxidize all organic matter, leaving behind only inorganic residues. The process typically follows three main stages: dehydration, volatilization, and carbon oxidation.

A weighed starch sample is first placed in a pre-ignited, tared crucible and heated gradually in a muffle furnace. The temperature is raised to approximately 550°C under carefully regulated airflow to ensure complete oxidation of organic constituents without loss of inorganic materials. The remaining inorganic residue, known as ash, is cooled in a desiccator and weighed to calculate the percentage of ash relative to the initial sample mass.

The equation used is:

Ash content (%) = (Weight of residue / Weight of dry starch sample)×100

At MtoZ Biolabs, all measurements are conducted using high-precision balances and temperature-controlled furnaces with digital monitoring systems. In addition, we employ thermogravimetric analysis (TGA) for detailed thermal profiling when quantitative mineral content differentiation is required. This combined approach enables comprehensive evaluation of inorganic composition and ensures the highest analytical reliability.

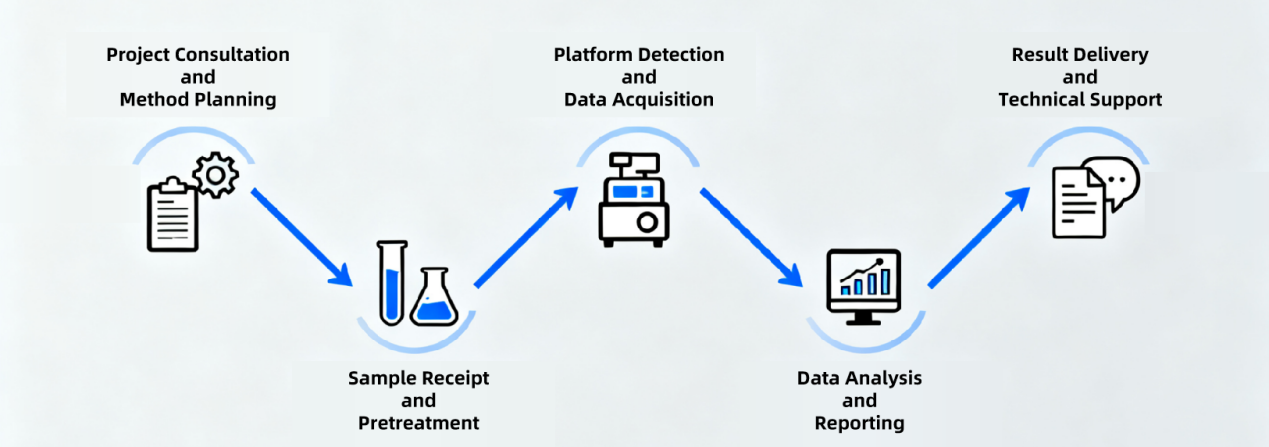

Analysis Workflow

Service Advantages

✔️Advanced Analytical Platform

Equipped with precision muffle furnaces and high-sensitivity microbalances, MtoZ Biolabs ensures accurate and reproducible ash quantification across diverse starch types.

✔️High Data Quality and Reliability

Each analysis follows internationally recognized methods with strict quality control to guarantee consistency and traceability of results.

✔️Comprehensive and Flexible Solutions

Our service covers native and modified starches, allowing customization of analytical parameters according to sample characteristics and project requirements.

✔️Expert Technical Support

Our experienced analytical chemists provide professional consultation, result interpretation, and methodological guidance throughout the project.

✔️Fast Turnaround and Transparent Reporting

Streamlined workflows and digital reporting systems enable rapid data delivery with clear documentation of experimental conditions and outcomes.

Applications

1. Food Industry

Ensures product purity, nutritional compliance, and process consistency for starch-based food ingredients, sweeteners, and thickeners.

2. Pharmaceutical Industry

Evaluates excipient purity and batch uniformity in tablet formulations and coating materials, supporting quality control.

3. Agricultural Product Assessment

Assists in evaluating starch extraction efficiency and raw material quality from various plant sources.

4. Biomaterials and Packaging

Controls mineral residue content in starch-based biodegradable films, ensuring mechanical integrity and environmental safety.

5. Chemical and Industrial Processing

Supports optimization of starch modification reactions and evaluation of catalyst or reagent residues.

6. Research and Development

Provides essential compositional data for starch structural studies, source tracing, and process optimization research.

Sample Submission Suggestions

1. Sample Type: Purified starch powders or raw materials containing starch from plant, microbial, or synthetic sources. If raw materials are provided, starch extraction will be performed by MtoZ Biolabs prior to analysis.

2. Sample Quantity: At least 10 g of starch or 60 g of fresh raw material; actual requirements depend on starch purity and experimental conditions.

3. Replicates: We recommend three or more biological replicates to ensure statistical reliability.

4. Packaging and Transport: Samples should be sealed in airtight containers, protected from moisture and contamination.

Note: For samples with limited availability or specific handling requirements, please contact MtoZ Biolabs for customized submission instructions.

How to order?