Vacant HydroxypropyI Starch Capsule Analysis Service | Pharmaceutical Excipient

Vacant hydroxypropyl starch capsule is a new type of pharmaceutical excipient capsule made from hydroxypropylated starch, featuring good biocompatibility and stability. Its principle is to analyze the physicochemical properties and structural characteristics of the capsule to evaluate its performance in drug inclusion, dissolution, and storage processes. Compared with traditional gelatin capsules, this material possesses better moisture resistance and adaptability, meeting the needs of different populations and formulations. Its applications are mainly focused on drug delivery and biologically related material research, providing support for formulation development and excipient evaluation.

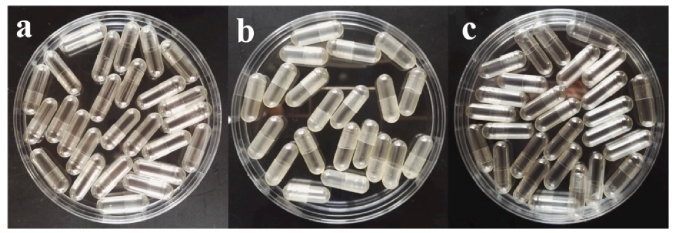

Song, F C. etal. International Journal of Biological Macromolecules, 2021.

Figure 1. Photographs of Hydroxypropyl Hydrolyzed Potato Starch Capsules with Different Composition.

Services at MtoZ Biolabs

Based on an advanced analytical platform, MtoZ Biolabs has launched the vacant hydroxypropyl starch capsule analysis service based on pharmaceutical excipient which can systematically evaluate the physicochemical properties and overall quality characteristics of hydroxypropyl starch capsules. This service provides key parameters and reliable data to support pharmaceutical formulation development, excipient evaluation, and quality control research. MtoZ Biolabs provides services including but not limited to the following:

1. Identification

Detect whether the sample contains hydroxypropyl starch to confirm the accuracy of its component source and product characteristics.

2. Sealing

Examine the closure integrity of the capsule to assess its ability to prevent leakage and moisture during drug storage and transportation.

3. Stability

Study the performance changes of the capsule under different conditions of temperature, humidity, and light to determine whether it can maintain quality over time.

4. Dissolution Characteristics

Evaluate the dissolution rate and solubility of the capsule in different media, analyzing its impact on drug release and bioavailability.

5. Moisture

Measure the moisture content of the capsule to avoid microbial growth caused by excessive moisture or brittleness caused by too little, thereby affecting storage stability.

6. Impurities

Test the possible levels of impurities in the sample to ensure product purity and safety.

7. Heavy Metals

Analyze the content of heavy metals in the sample to ensure compliance with pharmaceutical excipient safety standards.

8. Microorganisms

Detect potential microorganisms in the capsule to confirm compliance with harmless levels and avoid risks caused by contamination.

Sample Submission Suggestions

1. Sample Purity

It is recommended to avoid the influence of impurities, moisture, or contaminants in the sample to prevent interference with the analysis of physicochemical properties and quality indicators.

2. Sample Storage

Samples should be stored in dry, dark, and appropriate temperature conditions to prevent moisture absorption, oxidation, or structural changes, ensuring that properties do not change before testing.

3. Sample Transportation

During transportation, sealed containers should be used, and moisture-proof or cold chain conditions should be applied as needed to ensure the sample remains intact and stable before reaching the testing platform.

Service Advantages

1. Comprehensive Testing

Combining multiple analytical methods, it can systematically evaluate the physicochemical properties and quality characteristics of the capsule to ensure reliable data.

2. Accurate Results

Relying on an advanced testing platform, it can measure key parameters such as solubility, stability, moisture, and impurities with high precision.

3. Professional Support

Data analysis and quality evaluation are carried out by an experienced technical team to ensure standardized procedures and scientifically reliable conclusions.

4. High Efficiency and Convenience

Providing both standardized and customized testing solutions, it shortens testing cycles and improves the efficiency of research and quality control.

Applications

1. Formulation Development

The vacant hydroxypropyl starch capsule analysis service can be used to evaluate its suitability in different pharmaceutical formulations and support drug inclusion and release studies.

2. Quality Control

By testing the physicochemical indicators of the capsule, it provides data support for the evaluation of stability and consistency during production.

3. Drug Delivery Systems

The vacant hydroxypropyl starch capsule analysis service can help analyze the performance of capsules in oral and other administration routes, verifying their application potential in delivery systems.

4. Biomaterial Research

It is suitable for compatibility and functionality studies with biologically related materials, assisting in the development and optimization of new excipients and carriers.

FAQ

Q1: What Are the Differences in Testing Focus between Vacant Hydroxypropyl Starch Capsules and Gelatin Capsules?

A1: Hydroxypropyl starch capsules mainly focus on moisture, sealing, and stability, while gelatin capsules place more emphasis on the safety and suitability of animal-derived components. The physicochemical property testing indicators of the two differ.

Q2: Does the Service Support Customized Testing Items?

A2: Yes. Testing parameter ranges can be adjusted according to customer requirements, such as adding specific impurity detection or targeted stability studies.

Q3: Will Insufficient Sample Quantity or Batch Numbers Affect Testing?

A3: Yes. If the sample quantity or number of batches is too small, it may limit certain stability or repeatability tests. Therefore, it is recommended to provide representative sample quantities to obtain more comprehensive data.

How to order?