Rotational Viscometer Analytical Service

Rotational Viscometer Analytical Service is an analysis service that uses a rotational viscometer to evaluate the viscosity and rheological properties of liquid or semi-solid samples. In fields such as pharmaceuticals, food, cosmetics, chemicals, and materials science, accurate viscosity measurement is critical for quality control, formulation optimization, and process development. Rotational viscometer analysis measures the resistance exerted by the sample on the rotor under controlled shear conditions, thereby obtaining its viscosity, flow behavior, and shear characteristics, and providing scientific data support for material research, production, and quality control.

Technical Principles

The core principle of a rotational viscometer is that the rotor rotates in a liquid at a set speed while recording the resistance exerted by the sample on the rotor’s motion. This resistance causes torque deflection in the drive system, and the torque is proportional to the viscous resistance of the fluid, which allows the viscosity of the liquid to be calculated. By combining rotors of different geometries and sizes with adjustable rotation speeds, the instrument can cover a wide measurement range from low to high viscosity. Low-viscosity liquids typically require larger rotors and higher speeds, while high-viscosity liquids require smaller rotors and lower speeds. The final results are expressed in cP or mPa·s (numerically equivalent), providing both absolute viscosity values and insights into the flow behavior of samples under different shear conditions.

Sirok B. et al. Mineral wool: production and properties. 2008.

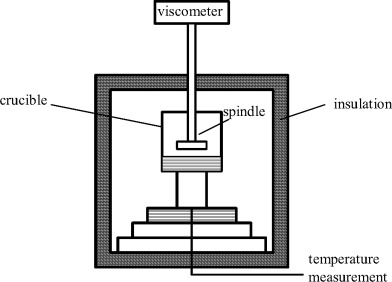

Figure 1. Rotational Viscometer

Services at MtoZ Biolabs

MtoZ Biolabs provides Rotational Viscometer Analytical Service to precisely measure the viscosity and rheological properties of liquids or semi-solids under different shear rates. This service is suitable for a wide range of sample types, including injectables, protein solutions, syrups, gels, ointments, and other polymer systems. It not only provides absolute viscosity values but also reveals the flow and stability characteristics of samples under practical conditions, offering scientific support for pharmaceutical formulation development, quality control, and formulation optimization.

Analysis Workflow

The general process of Rotational Viscometer Analytical Service includes the following steps:

1. Sample Preparation

Depending on the sample type (solution, suspension, gel, or semi-solid), homogenize the sample and remove air bubbles to ensure representativeness and stability during measurement.

2. Instrument Setup

Select the appropriate rotor and rotation speed, and set the testing temperature and shear rate conditions.

3. Testing Process

Immerse the rotor into the sample and conduct the rotational test under controlled conditions, measuring the resistance of the sample against the rotor in real time and converting it into torque signals.

4. Data Analysis

Generate curves showing viscosity changes with shear rate, or record viscosity variation over time at a fixed shear rate, to evaluate the flow behavior and stability of the sample.

5. Report Output

Provide a complete analysis report, including experimental conditions, testing curves, viscosity ranges, and interpretation of the results.

Service Advantages

1. Broad Applicability

Rotational Viscometer Analytical Service can cover testing needs ranging from low-viscosity solutions to high-viscosity semi-solids such as injectables, syrups, gels, and ointments.

2. High Precision and Reliability

Supported by advanced rotational viscometer platforms, the service ensures accurate and reproducible data under different shear rates and temperature conditions.

3. Customized Testing Solutions

Rotor type, rotation speed, and testing environment can be flexibly adjusted according to the client’s research goals and application requirements, meeting the diverse needs of formulation development and quality control.

Sample Submission Suggestions

1. Sample Types

Acceptable samples include liquids, suspensions, syrups, protein solutions, gels, and semi-solid samples such as ointments and creams.

2. Storage and Transportation

Samples should be stored in sealed containers protected from light, and liquids or easily degradable samples are recommended to be transported under low-temperature conditions.

It is recommended to contact the MtoZ Biolabs technical team prior to sample submission to obtain detailed and tailored guidelines for sample preparation and submission.

Applications

1. Pharmaceutical Field

Evaluate the viscosity and flow properties of formulations such as injectables, protein solutions, syrups, gels, and ointments to ensure smooth administration, uniformity, and patient experience, while also providing a basis for formulation optimization and stability studies.

2. Food Industry

Applied to texture and consistency control of beverages, dairy products, sauces, and syrups to ensure product sensory consistency and production process stability.

3. Cosmetics and Personal Care Products

Analyze the rheological characteristics of creams, gels, and lotions to optimize formulation spreadability, absorption, and consumer usability.

How to order?