Pharmaceutical Intermediates Analysis Service

- Antibiotic drugs (e.g., macrolides, tetracyclines, β-lactams, quinolones)

- Cardiovascular drugs (e.g., aryloxyalcoholamines, nitrates, cardiac glycosides)

- Antipyretic and analgesic drugs (e.g., trifluoromethylaniline)

- Sedative-hypnotic drugs (e.g., trifluoroethanol)

- Chemotherapy drugs

Pharmaceutical intermediates are defined as chemical compounds that are deliberately synthesized and incorporated as essential precursors in the production of Active Pharmaceutical Ingredients (APIs). These intermediates often possess well-defined chemical structures and properties, serving as crucial building blocks that contribute directly to the final structure of the API. They are primarily associated with the synthesis of small molecule drugs, where multiple sequential steps are required to construct the final active substance. Because intermediates influence both the efficiency of chemical reactions and the quality of the final API, their analysis for identity, purity, and impurity content is indispensable. Ensuring the quality of intermediates reduces the risk of unwanted by-products, increases synthetic yield, and guarantees that the final API meets strict pharmaceutical quality standards.

Service at MtoZ Biolabs

MtoZ Biolabs offers a comprehensive Pharmaceutical Intermediates Analysis Service designed to support drug discovery, development, and manufacturing. Our advanced analytical platforms, including mass spectrometry, nuclear magnetic resonance, chromatography, and spectroscopic methods, allow us to deliver reliable and regulatory-ready results. By combining technical expertise with customized workflows, we ensure that clients receive accurate data and actionable insights for every project.

Our service includes:

💠Composition Analysis

We determine the overall chemical composition of pharmaceutical intermediates, identifying key structural fragments, functional groups, and associated compounds. This ensures that the intermediate matches the intended synthetic design and contributes effectively to API synthesis.

💠Deformulation

We reverse-engineer formulations to reveal the composition of intermediates, excipients, and additives. This provides valuable insight into synthetic pathways, facilitates process optimization, and supports comparative studies between batches or manufacturers.

💠Purity Analysis

Using HPLC, UPLC, GC, and spectroscopic methods, we quantify the purity levels of intermediates and confirm the absence of unintended compounds. High purity ensures efficiency in subsequent reactions and reduces the risk of impurity carryover into the final API.

💠Impurity Analysis

We detect and quantify process-related impurities, residual solvents, trace metals, and degradation products. Impurity profiling helps in identifying potential risks early, guiding process improvements, and supporting regulatory compliance.

Through these services, MtoZ Biolabs provides end-to-end support to ensure that pharmaceutical intermediates meet the highest quality standards, enabling safe, consistent, and efficient API production.

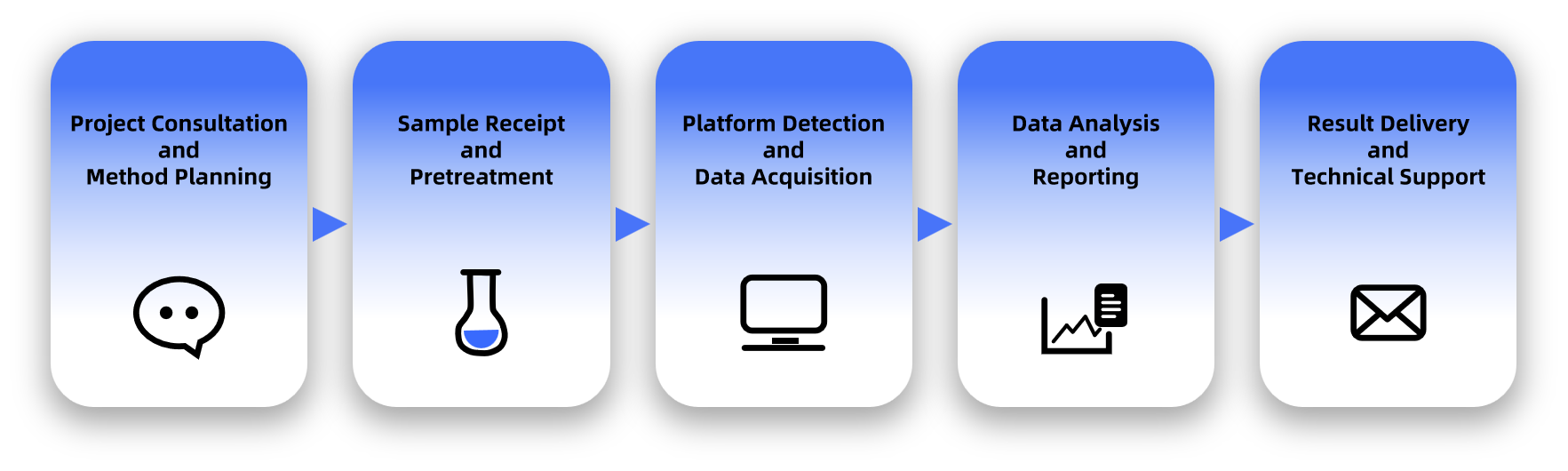

Analysis Workflow

Service Advantages

☑️Customized workflows designed to align with project-specific requirements and regional regulatory expectations.

☑️Stringent quality management system ensuring accuracy, reproducibility, and reliability of results.

☑️Efficient turnaround times supported by professional consultation and technical support.

☑️End-to-end solutions covering sample preparation, analysis, data processing, and result interpretation.

☑️Our pricing is transparent, no hidden fees or additional costs.

Applications

The Pharmaceutical Intermediates Analysis Service at MtoZ Biolabs supports a wide range of scientific and industrial applications:

1. Drug Discovery and Development

Characterization of intermediates ensures that novel synthetic routes are viable, enabling efficient progression from early-stage compounds to candidate APIs.

2. Process Optimization

Monitoring intermediates helps identify reaction bottlenecks, control impurities, and improve yields during chemical synthesis.

3. Quality Control in Manufacturing

Routine analysis of intermediates guarantees consistency across production batches and prevents deviations that could affect final drug quality.

4. Regulatory Compliance

Comprehensive intermediate analysis provides essential data for Chemistry, Manufacturing, and Controls documentation, supporting global regulatory submissions.

5. Stability and Degradation Studies

Analysis under stress conditions reveals potential degradation pathways of intermediates, guiding the development of robust storage and handling strategies.

Sample Submission Suggestions

MtoZ Biolabs accepts a wide range of pharmaceutical intermediates for analysis, covering various therapeutic categories. Clients are encouraged to provide detailed background information on the synthetic route and intended API, so that customized analytical workflows can be applied. Our accepted pharmaceutical intermediates include but are not limited to the following:

*Note: If you have special sample types or require additional guidance, please contact us for personalized support before sample preparation.

Deliverables

1. Comprehensive Experimental Details

2. Materials, Instruments, and Methods

3. Total Ion Chromatogram & Quality Control Assessment (project-dependent)

4. Data Analysis, Preprocessing, and Estimation (project-dependent)

5. Bioinformatics Analysis

6. Raw Data Files

Related Services

Drug Composition Testing Service

Drug Microbial Limit Testing Service

Pharmaceutical Impurity Analysis Service

How to order?