MicroED for New Material Analysis Service

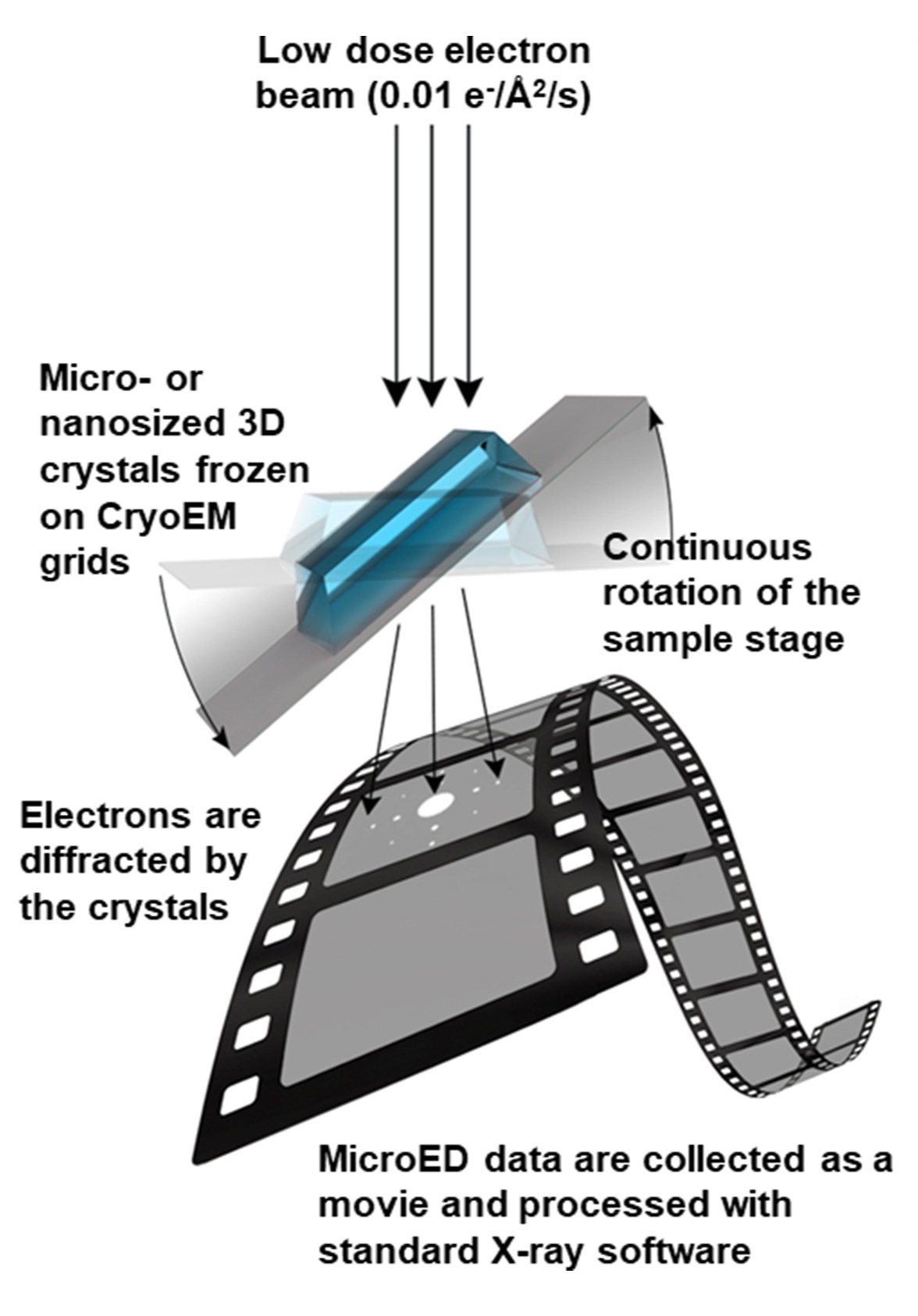

- Electrons scatter much more strongly than X-rays, enabling the acquisition of high-quality diffraction data even from nanocrystalline samples.

- Continuous-rotation data collection mimics the approach used in single-crystal X-ray diffraction (SCXRD), capturing diffraction patterns from multiple crystal orientations.

- 3D reconstruction and structure determination are performed using specialized crystallographic software such as SHELXT, Olex2, and Phenix for precise model building and refinement.

- The method supports cryogenic operation, which minimizes radiation damage and preserves the native structural state of the sample.

MicroED for New Material Analysis Service is a structural characterization solution that applies Microcrystal Electron Diffraction (MicroED) to determine the crystal structures and confirm the polymorphs of novel material samples—typically in the form of submicron-sized microcrystals or solid-state materials that are difficult to crystallize.

In advanced materials research, understanding the microstructure of a material is essential for interpreting its properties and functionalities. Traditional single-crystal X-ray diffraction (SCXRD) remains the gold standard for defining atomic-level structures, but it relies on the availability of large, high-quality single crystals. However, many cutting-edge materials—such as metal-organic frameworks (MOFs), covalent organic frameworks (COFs), pharmaceutical crystals, and inorganic nanoparticles—are often only available as microcrystalline, nanocrystalline, or non-ideal solid forms, making them incompatible with conventional diffraction techniques.

MicroED is a next-generation technique for structural analysis. Based on a transmission electron microscopy (TEM) platform, MicroED uses an electron beam instead of X-rays to collect high-resolution diffraction data from extremely small crystals. It enables structural elucidation of a wide range of materials, including proteins, small molecules, and complex materials such as MOFs and COFs.

MtoZ Biolabs offers MicroED for New Material Analysis Service to support structural determination of novel materials that are challenging for conventional techniques like SCXRD. This service provides researchers in life sciences, pharmaceutical chemistry, inorganic chemistry, functional materials, and crystal engineering with specialized solutions for microcrystal structure determination.

Technical Principles

Danelius E. et al. Structural Biology. 2023.

The core principle of MicroED is based on the combination of strong electron scattering and continuous rotation diffraction collection:

Analysis Workflow

MicroED for New Material Analysis Service at MtoZ Biolabs follows a standardized workflow to ensure data quality and reproducibility:

1. Sample Evaluation and Preparation

Includes sample preprocessing (grinding, dilution, sieving, etc.) and cryo-TEM grid preparation.

2. Diffraction Data Collection

High-resolution transmission electron microscopy (TEM) is used to collect continuous-rotation diffraction patterns from target microcrystals under low-dose conditions, with compatibility for cryogenic environments (e.g., liquid nitrogen cooling).

3. Data Processing and Structure Determination

Diffraction images are indexed, integrated, and normalized;

Crystallographic software is used to solve unit cell parameters and atomic coordinates, build a 3D structural model, and refine the structure.

4. Report Delivery

Deliverables include structural coordinate files (.cif), electron density maps, crystal images, and a detailed technical report.

Applications

MicroED for New Material Analysis Service supports a broad range of applications, including:

Polymorph Identification and Crystal Structure Determination

3D structural modeling of new drug candidates, polymorphic forms, and co-crystals.

MOFs and COFs

Ideal for porous materials and high-throughput screening products where large single crystals are difficult to grow.

Functional Nanomaterials and Metal Cluster Studies

Applicable to metal oxides, quantum dots, metal–ligand assemblies, and other nanoscale systems.

Inorganic Solids, Minerals, and Hybrid Phase Identification

Provides high-resolution structure validation for poorly crystalline, mixed-phase, or polycrystalline inorganic materials.

Structural Validation and Computational Prediction Support

Experimental validation for DFT calculations and crystal structure predictions.

FAQ

Q. How does MicroED Differ from Traditional Single-Crystal X-Ray Diffraction (SCXRD)?

SCXRD requires crystals at least tens of microns in size, whereas MicroED can resolve 3D structures from submicron- to nanometer-scale crystals. It is particularly suited for difficult-to-crystallize or multiphasic samples. The data processing workflows are similar, but MicroED uses electrons instead of X-rays, offering much stronger scattering.

Q. What Types of New Materials can be Analyzed using MicroED?

MicroED is suitable for a wide range of materials, including but not limited to MOFs, COFs, organic/inorganic hybrid compounds, pharmaceutical polymorphs, co-crystals, metal clusters, quantum dots, and inorganic minerals. As long as crystallinity is present, MicroED can be attempted for both research-grade and application-driven projects.

Q. Can MicroED Still be Used If the Sample is Multiphasic or Poorly Crystalline?

Yes. MicroED can selectively target well-diffracting regions within a multiphase sample to solve single-phase structures. For materials with low crystallinity, we will assess their diffraction potential and provide a technical feasibility evaluation.

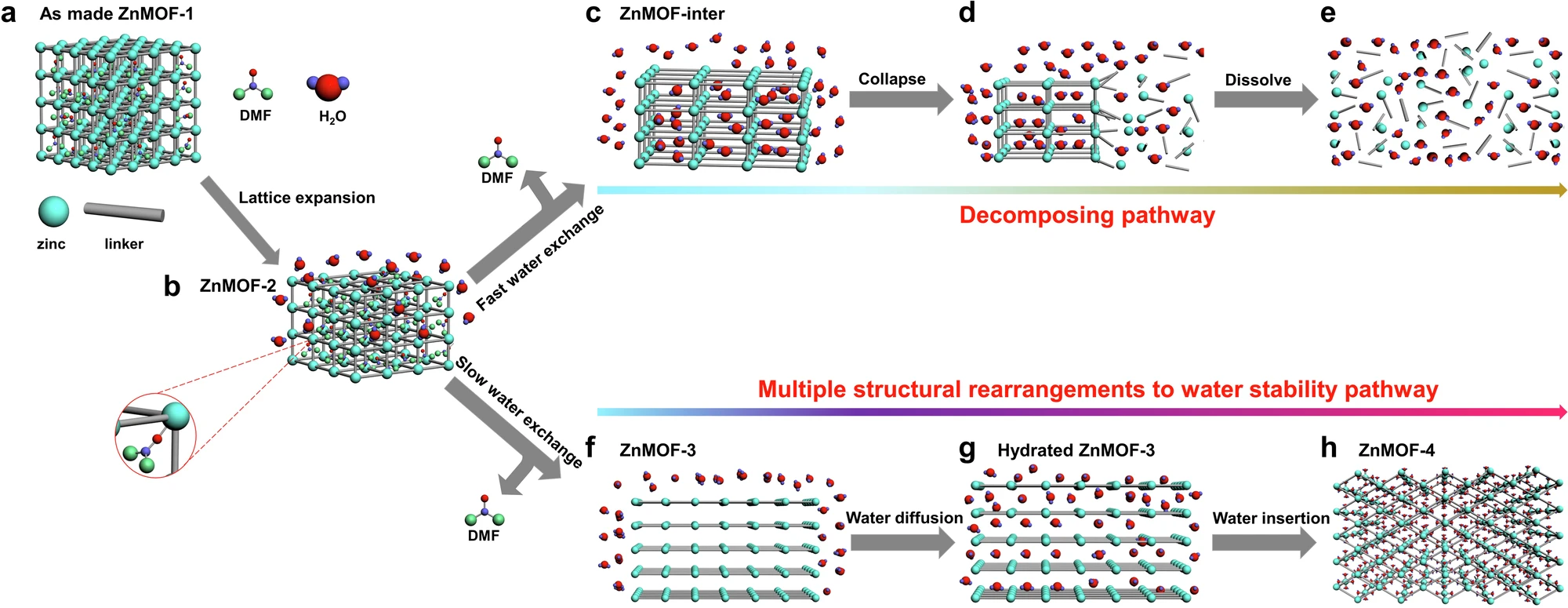

Case Study

This study used MicroED technology to successfully analyze the key intermediate structures of Zn-based metal organic framework (ZnMOF-1) in the hydrolysis process. In particular, under conditions where traditional single crystal X-ray diffraction could not obtain large-size crystals, MicroED revealed a highly disordered intermediate structure in one of the hydrolysis pathways. Studies have shown that ZnMOF-1 can transform along two paths in water: one is structural reorganization to form water-stable ZnMOF-4, and the other is structural disintegration and dissolution. The introduction of MicroED technology enabled researchers to obtain the three-dimensional structural information of this type of transition state crystals for the first time, clarifying the cooperative dissociation mechanism involving water molecules, which is of great significance for understanding the dynamic stability of MOF materials and designing hydrolysis-resistant MOFs.

Chen S. et al. Nat Commun. 2024.

How to order?