Glycoengineering Microarray Service

- Antibody Glycoform Optimization

- Cell Therapy Product Development

- Vaccine and Glycan-Conjugated Drug Design

Glycoengineering Microarray Service is a glycan functional assessment service based on a high-density microarray platform, specifically designed to systematically examine the impact of glycoengineering strategies on glycan expression profiles and their biomolecular recognition properties. This service involves immobilizing engineered cells, glycoproteins, or glycan products onto the surface of microarray chips, followed by detection using labeled lectins, antibodies, or receptor proteins to generate glycan binding profiles, recognition patterns, and functional changes.

Natural glycosylation is inherently heterogeneous and complex, making it difficult to precisely control-posing significant challenges in biopharmaceutical development, vaccine optimization, and cell-based therapies. To address this, glycoengineering has emerged as a valuable approach that employs gene editing, enzymatic synthesis, or metabolic reprogramming to regulate glycan modifications.

The glycoengineering microarray is a high-throughput platform used to systematically evaluate the glycan structures and associated biological functions of cells or protein products modified through glycoengineering techniques. By immobilizing glycan structures, glycoproteins, or cell lysates derived from engineered samples onto the chip surface and detecting their interactions with molecules such as antibodies, lectins, or receptor proteins, the technology reveals how glycoengineering influences recognition specificity, functional activity, and downstream signaling pathways.

MtoZ Biolabs offers Glycoengineering Microarray Service to comprehensively evaluate how different glycoengineering strategies affect glycan structures and their molecular recognition functions. This service supports the analysis of glycosylation alterations resulting from interventions such as gene editing or glycosyltransferase modulation. It provides full-spectrum insights into the interaction patterns between glycans and antibodies, lectins, or receptor proteins.

Heimburg-Molinaro J. et al. Mol Cell Proteomics. 2024.

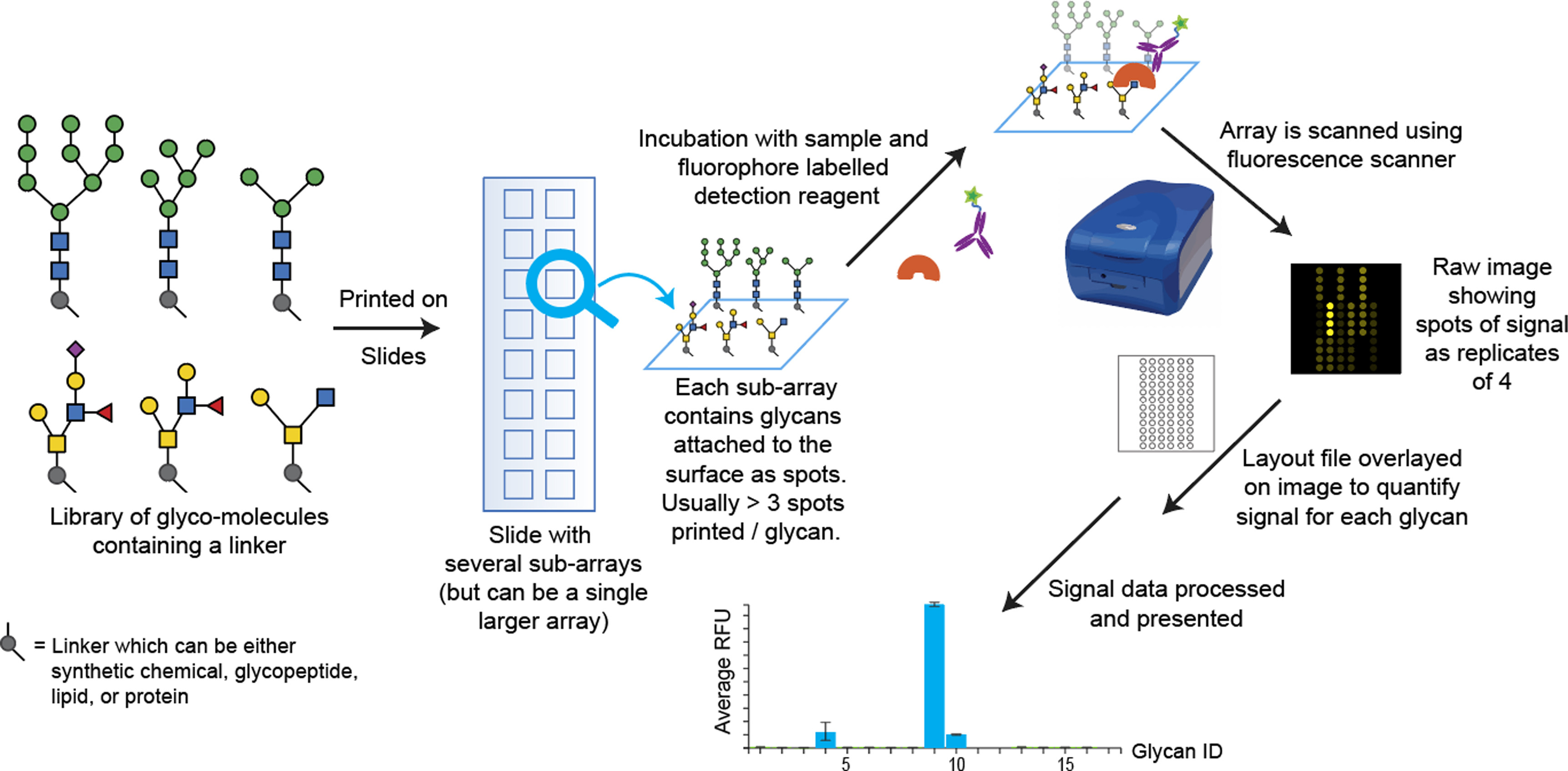

Figure 1. Overview of the process of glycan microarrays.

Analysis Workflow

The main workflow of the Glycoengineering Microarray Service is as follows:

1. Sample Extraction and Purification

Glycoproteins, glycans, or glycopeptides are extracted from engineered cells, with background interference removed to ensure structural integrity and representativeness.

2. Microarray Chip Preparation

The extracted glycan samples are immobilized onto the microarray surface via chemical conjugation or non-covalent methods, forming a highly comparable chip layout.

3. Binding Reaction and Incubation

Labeled recognition molecules (e.g., lectins, antibodies) are incubated with the chip to assess the binding characteristics between glycans and functional molecules.

4. Fluorescence Scanning and Data Acquisition

A laser scanner is used to detect fluorescence signals and generate intensity maps for each spot on the array.

5. Data Analysis and Report Generation

Signal intensities and background values from all spots are integrated for statistical analysis, clustering heatmap generation, and binding profile construction, with a standardized analytical report delivered.

Service Advantages

High Throughput and Efficiency: Enables simultaneous detection of large sample sets, allowing systematic evaluation of functional differences across multiple glycoengineering strategies within a single experiment.

High Sensitivity: Utilizes a highly sensitive fluorescence scanning platform to accurately capture molecular recognition events involving low-abundance glycans.

Versatile Platform Compatibility: Supports a wide range of research objectives, including antibody glycoform screening, glycosyltransferase function validation, glycan optimization for cell therapy, and vaccine target development-flexibly accommodating diverse experimental designs.

Specialized Technical Support: An experienced team provides end-to-end guidance, from sample preparation to data analysis.

Sample Submission Suggestions

Sample Types

A variety of sample types are supported, including glycoengineered cell lysates, recombinant glycoproteins, and purified glycans or glycopeptides.

Storage and Shipping

Samples should be stored at 4°C for short-term preservation. For long-term storage, –80°C freezing is recommended. All samples should be shipped on dry ice.

Additional Notes

To ensure optimal detection results, we recommend discussing your experimental goals and sample background with our technical team prior to submission. A customized sample preparation and shipping guide will be provided.

Applications

Application examples of the Glycoengineering Microarray Service:

Evaluate the impact of different glycoengineering strategies on Fc region glycosylation to enhance antibody-dependent cellular cytotoxicity (ADCC) or extend serum half-life.

Analyze changes in cell surface glycans following glycoengineering modifications to support quality control and characterization of cell therapy products such as CAR-T cells and stem cells.

Screen for specific interactions between immune-relevant glycans and recognition molecules to aid in antigen selection and optimization of glycan conjugation strategies for vaccines and therapeutics.

Related Services

How to order?