Capillary Rheometer Analytical Service

- High Precision and Reliability: Advanced capillary rheometers are used to accurately measure viscosity and rheological properties under high shear, ensuring reliable and precise data.

- Professional Technical Support: An experienced technical team provides guidance in experimental design, data interpretation, and process optimization.

- Customizable Service: Testing conditions such as temperature, shear rate, and testing mode can be adjusted according to specific client requirements to obtain the most relevant rheological data.

Capillary Rheometer Analytical Service is a specialized analysis service used to measure the rheological properties of materials under high shear rates. Capillary rheometer analysis is a professional physicochemical characterization technique that is widely applied in the rheological studies of polymer materials, pharmaceutical excipients, and biopolymers. This technique is mainly used to evaluate the flow behavior of substances under high shear rates, including the viscosity of melts or solutions, the relationship between shear stress and shear rate, and the flow and processing performance during manufacturing.

Technical Principles

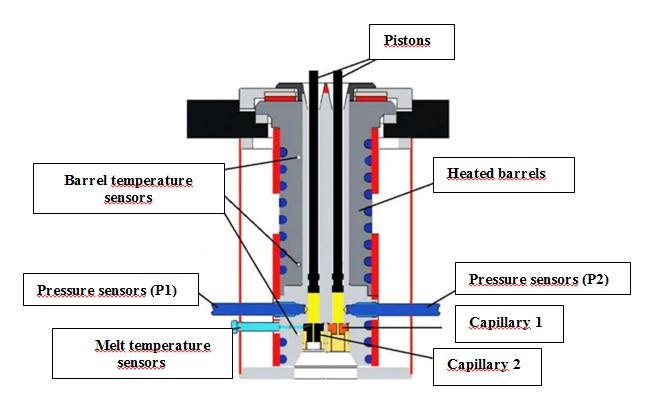

The technical principle of capillary rheometer analysis is based on fluid mechanics and shear flow theory: the sample is extruded through a narrow capillary at a controlled temperature under constant pressure or constant flow rate conditions. By measuring the outlet pressure and flow rate, the relationship between shear stress and shear rate is calculated, thereby obtaining the viscosity curve of the material under different shear conditions.

Bata A. et al. J Phys. 2018.

Figure 1. Capillary Rheometer Conceptual Layout

Services at MtoZ Biolabs

Based on high-precision capillary rheometers, MtoZ Biolabs provides Capillary Rheometer Analytical Service to evaluate the rheological properties and processing adaptability of materials. The service includes viscosity measurement, shear stress-shear rate curve plotting, and viscoelastic property analysis, offering scientific and reliable data support for material development, process optimization, and quality control.

1. Viscosity Measurement

Determine viscosity variation curves of materials under different shear rates to analyze their flow behavior.

2. Rheological Property Analysis

Evaluate processing adaptability and performance of materials under high shear conditions through the relationship between shear stress and shear rate.

3. Testing Under Different Environmental Conditions

Assess material flow properties under controlled temperatures to simulate actual processing conditions.

Service Advantages

Analysis Workflow

The analytical process of Capillary Rheometer Analytical Service generally includes the following key steps:

1. Sample Preparation

Pre-treat the sample according to its state (powder, granule, or melt) to ensure uniformity and suitability for instrument measurement.

2. Instrument Setup

Select the appropriate capillary size and set testing temperature, pressure, and shear rate range.

3. Testing

Extrude the sample through the capillary under controlled conditions and record data such as pressure, flow rate, and shear rate in real time.

4. Data Processing

Use specialized software to convert raw data into shear stress-shear rate curves and calculate viscosity, rheological index, and other flow parameters of the sample.

5. Result Analysis and Report

Evaluate the processing adaptability, viscosity stability, and shear response characteristics of the sample based on rheological curves, and generate a complete analysis report.

Applications

Application examples of Capillary Rheometer Analytical Service:

1. Material Development

Measure the viscosity characteristics of polymers, copolymers, and their melts to provide data support for modification, formulation optimization, and process design.

2. Quality Control and Consistency Verification

Monitor rheological differences in raw materials or between batches to ensure production consistency and product performance stability.

3. Performance Studies of Functional Materials

Analyze the flow characteristics of high-viscosity biomaterials, drug carriers, or food excipients to provide a basis for functional performance evaluation.

How to order?