TG-FTIR-GCMS Analytical Service

TG-FTIR-GCMS combined analysis is a multidimensional analytical approach that integrates thermogravimetric analysis (TG), Fourier-transform infrared spectroscopy (FTIR), and gas chromatography–mass spectrometry (GC-MS) on a single platform. It is designed to monitor real-time mass changes, the release of volatile products, and their chemical compositions during the thermal decomposition of materials. The basic principle involves recording the sample’s mass loss as a function of temperature via TG, while simultaneously directing the evolved gases to FTIR and GC-MS. FTIR is used for identifying functional groups, whereas GC-MS enables qualitative and quantitative analysis of specific chemical components.

TG-FTIR-GCMS analytical service is widely applied in thermal stability evaluation of polymeric materials, pyrolysis mechanism studies of flame retardants, identification of polymer additives, analysis of pyrolytic gas pollutants, compositional analysis of composite materials, and thermal emission profiling of environmental samples. The synergistic advantage of this multidimensional technique makes TG-FTIR-GCMS a powerful tool for elucidating thermal behavior and decomposition pathways of complex samples, with significant application value in materials science, environmental science, chemical engineering, and failure analysis.

Services at MtoZ Biolabs

Based on thermogravimetric analyzer (TG), Fourier-transform infrared spectrometer (FTIR), and gas chromatography–mass spectrometry (GC-MS) platforms, the TG-FTIR-GCMS analytical service provided by MtoZ Biolabs enables comprehensive analysis of mass changes, gas components, and molecular structural information during the thermal decomposition of samples. The service includes thermal degradation, volatile component trapping, and qualitative and quantitative gas analysis, ensuring the acquisition of high-precision data on thermal stability, decomposition products, and their structures. It is widely applied in studies of material thermal behavior, polymer degradation analysis, and component characterization.

Analysis Workflow

1. Sample Preparation and Weighing

The target sample is weighed and loaded into a thermogravimetric analysis (TGA) crucible, ensuring uniformity and strong representativeness of the sample.

2. Thermogravimetric Analysis (TG)

The sample is heated under preset heating rates and atmospheric conditions, and the mass change curve during the pyrolysis process is recorded.

3. Real-Time Gas Transfer

Volatile gases generated during pyrolysis are synchronously transferred through a high-temperature inert transfer system to the FTIR and GC-MS modules.

4. Gas Composition Analysis

FTIR is used to detect functional group information in the gases, while GC-MS further separates and identifies specific volatile organic compound components.

5. Data Integration and Interpretation

Data from TG, FTIR, and GC-MS are integrated to systematically analyze and visualize the sample’s thermal stability, decomposition pathways, and gas composition.

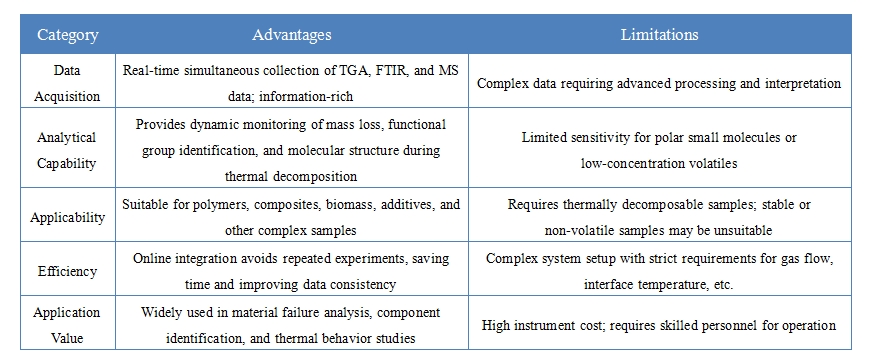

Advantages and Limitation

Applications

1. Thermal Stability Analysis of Polymeric Materials

TG-FTIR-GCMS analytical service can be applied to the study of thermal decomposition behavior in polymeric materials such as plastics, rubbers, and coatings, enabling the evaluation of their thermal stability, degradation pathways, and volatile components.

2. Mechanistic Study of Flame Retardants and Additives

By analyzing the types and changes of gases released during pyrolysis, this service reveals the decomposition characteristics and mechanisms of flame retardants, antioxidants, and other additives.

3. Pyrolysis Product Evaluation of Biomass and Waste

TG-FTIR-GCMS analytical service is used for the analysis of pyrolysis gases from lignin, cellulose, biomass pellets, and solid waste, providing valuable data for energy conversion applications and pollution control strategies.

4. Safety Assessment of Food and Packaging Materials

By detecting the volatile organic compounds (VOCs) released from food packaging materials during the heating process, it is ensured that they meet the safety standards for food contact materials.

Case Study

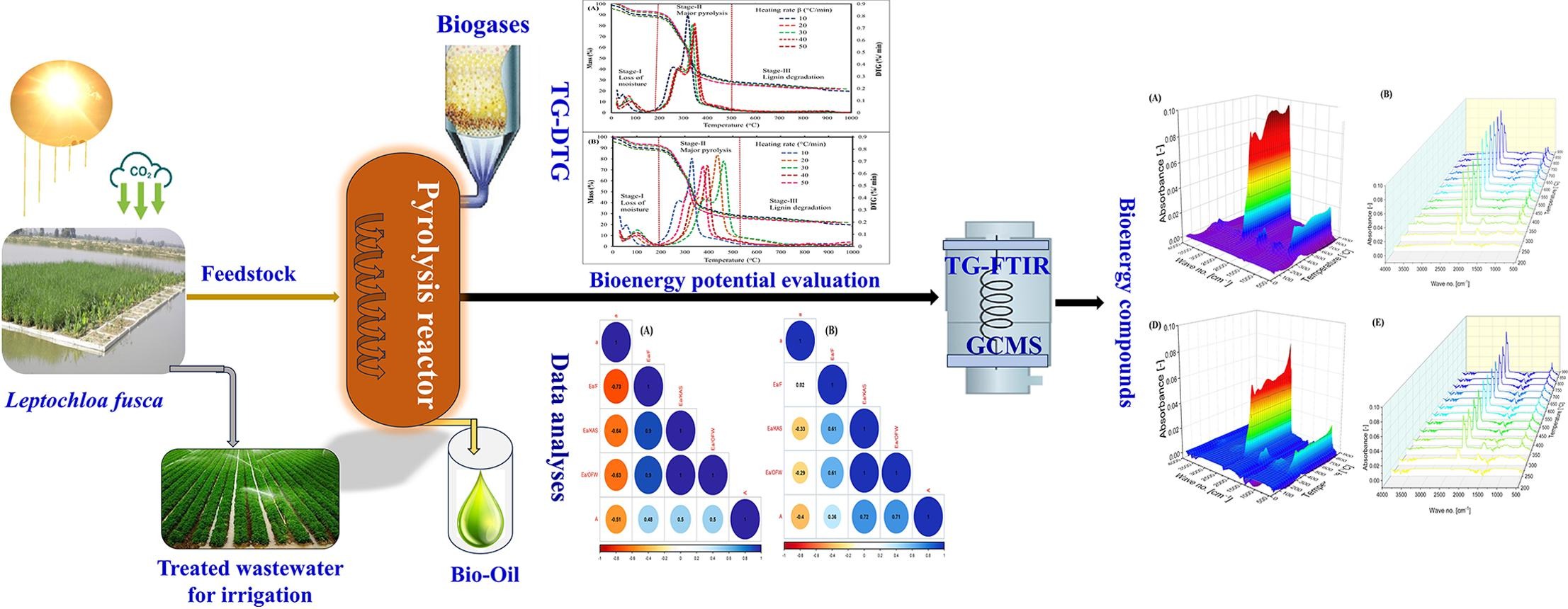

1. Assessment of Leptochloa Fusca Wastewater Biomass through TG-FTIR-GCMS and Machine Learning Tools

This study aims to evaluate the potential of Leptochloa fusca grown in wastewater as a feedstock for bioenergy and biochemical production. The research focused on biomass samples of Leptochloa fusca derived from wastewater environments. Pyrolysis experiments combined with TG-FTIR-GCMS analytical technology were employed to systematically analyze the composition and evolution of pyrolysis products, while various machine learning models were used to model and predict the pyrolysis process. The results showed that the biomass could effectively release various organic compounds with energy and chemical utilization value during pyrolysis, exhibiting good thermal stability and energy conversion efficiency. The study concludes that Leptochloa fusca is a sustainable source of bioenergy, and that TG-FTIR-GCMS technology, together with machine learning approaches, provides effective support for evaluating pyrolysis performance and predicting product outcomes.

Ishfaq, M. et al. Energy Conversion and Management, 2024.

Figure 1. The Graphical Abstract of this Study.

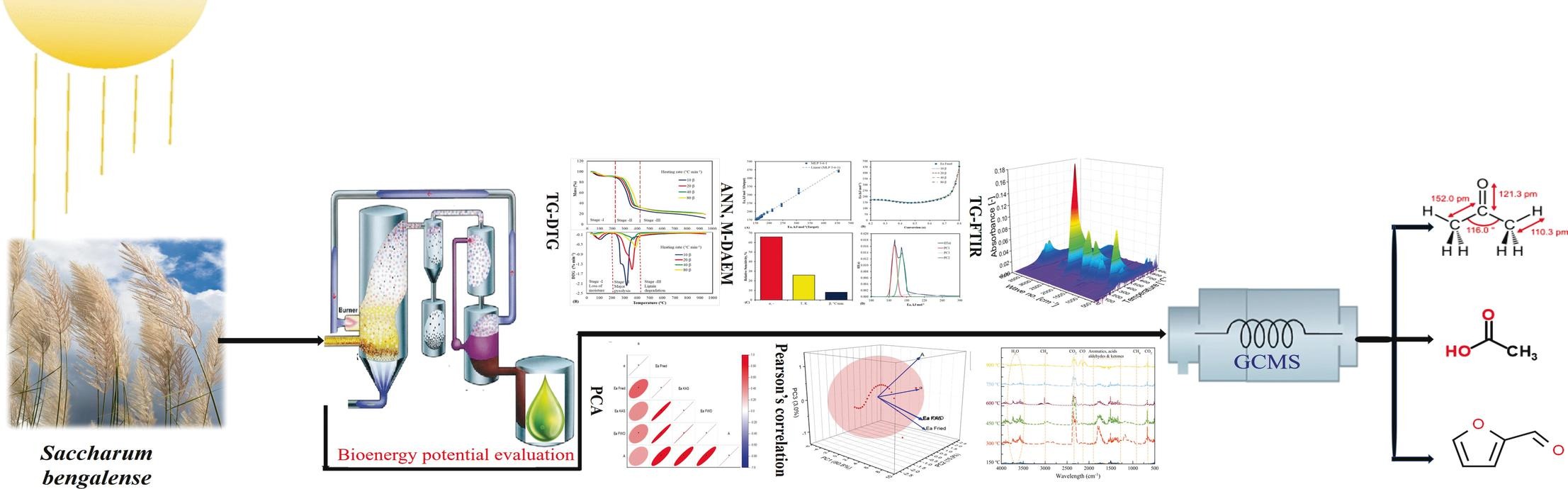

2. Bioenergy Potential of Saccharum Bengalense by TG-FTIR-GCMS

This study aims to evaluate the pyrolysis potential of Saccharum bengalense as a biomass energy feedstock. The research focused on dried Saccharum bengalense plant samples. TG-FTIR-GCMS coupled technology was used to comprehensively analyze the pyrolysis kinetics and product composition, and multiple models were introduced for reaction kinetics calculations. Additionally, machine learning methods were applied to predict and validate the pyrolysis data. The results demonstrated that the plant could produce a variety of organic compounds during pyrolysis, showing favorable pyrolytic behavior and energy conversion potential. The reaction process exhibited multi-step kinetic characteristics, and the machine learning models achieved high accuracy in data fitting. The study concludes that Saccharum bengalense has promising potential as a renewable energy material, and the combination of TG-FTIR-GCMS analysis with machine learning is an effective approach for evaluating biomass pyrolysis performance.

Asghar, A. et al. Chemical Engineering Journal, 2023.

Figure 2. The Graphical Abstract of this Study.

FAQ

Q1: How Do the TG, FTIR, and GC-MS Modules Coordinate with Each Other?

A1: During the heating process in the thermogravimetric (TG) module, the evolved gases are first transferred to the FTIR module for functional group analysis, and then a portion of the gas is directed to the GC-MS system for compound separation and structural identification. This integrated workflow enables correlative analysis of thermal behavior, gas evolution timing, and molecular composition.

Q2: Are Different Heating Rates or Atmospheric Conditions Supported?

A2: Yes. Various heating rates can be selected based on sample requirements. The system also supports controlled atmospheres such as inert gas or oxygen to simulate thermal behavior under different environmental conditions.

How to order?