Sieve Analysis Service

- Customized sieve ranges to match client-specific requirements.

- Rigorous quality control for accuracy and reproducibility.

- Rapid turnaround times and comprehensive reporting.

- Dedicated scientific support from our experienced team.

Sieve Analysis Service refers to the systematic determination of particle size distribution by passing a sample through a series of sieves and quantifying the material retained at each level. Particle size distribution is a fundamental property that affects the performance, stability, and quality of powders, granules, and raw materials across a wide range of industries. In pharmaceuticals, particle size directly influences drug dissolution rate, bioavailability, and compressibility. In food science, construction, chemicals, and metallurgy, it affects texture, flowability, and product uniformity. Understanding and controlling particle size distribution is therefore essential for ensuring product quality, compliance with regulatory standards, and consistency in manufacturing processes.

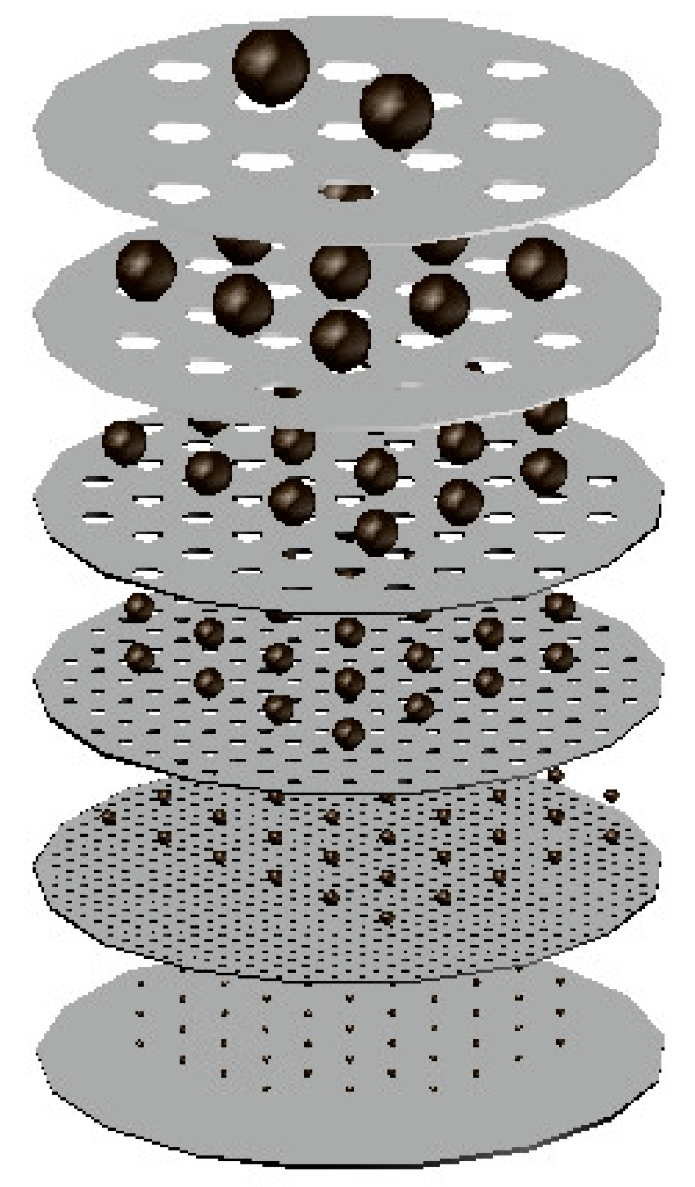

Sieve analysis is one of the oldest and most reliable techniques for determining particle size distribution. It works by mechanically separating particles according to size using a stack of sieves with progressively smaller mesh apertures. Each fraction retained on a sieve represents a specific size class, and the cumulative results provide a detailed profile of the sample's particle size distribution. While simple in principle, sieve analysis remains highly effective for materials in the size range of approximately 20 microns to several millimeters.

Aliukov, S. et al. Appl. Sci. 2021.

Figure 4. A Sketch of a Sieve Analysis

Service at MtoZ Biolabs

MtoZ Biolabs provides a professional Sieve Analysis Service that applies standardized methods to deliver accurate and reproducible particle size distribution data. Using carefully selected stacks of sieves with progressively smaller apertures, samples are fractionated by size, and the retained material on each sieve is quantified to calculate percentage distributions.

Our laboratory is equipped to handle a wide variety of materials, including powders, granules, and pharmaceutical raw ingredients. Depending on the sample type, dispersion can be achieved through controlled vibration, air flow, or liquid suspension to ensure efficient passage through the mesh and reliable separation of size fractions.

MtoZ Biolabs supports both research and industrial projects by providing detailed particle size profiles that are essential for product development, process optimization, and quality control.

Service Advantages

By choosing our Sieve Analysis Service, clients benefit from:

Sample Submission Suggestions

1. Sample Types

Powders, granules, pharmaceutical excipients, tablet raw materials, food powders, and more.

2. Sample Amount

About 100 g is suitable for standard sieve stacks, while 10–20 g is sufficient for Sonic Sifter or Air Jet methods.

3. Particle Size Range

Sieve analysis works best for particles ≥45 µm. Air Jet sieving can measure down to 20 µm, but for particles below 45 µm, more precise particle sizing techniques are recommended.

4. Labeling and Documentation

Provide sample identification, expected particle size range, and specific analysis objectives.

If you have special sample types or require additional guidance, please contact us for personalized support before sample preparation.

Applications

Sieve analysis plays a crucial role across multiple industries due to its simplicity, reliability, and reproducibility. Applications include:

1. Pharmaceutical Industry

Determination of particle size distribution in active pharmaceutical ingredients (APIs), excipients, granules, and tablet raw materials. Particle size affects drug dissolution rate, bioavailability, flow properties, and compressibility.

2. Food and Agriculture

Analysis of flour, sugar, grains, and other powders to ensure uniformity and consistency in texture, taste, and processing behavior.

3. Materials Science and Nanotechnology

Characterization of powders and granules used in ceramics, polymers, catalysts, and advanced materials.

4. Construction and Engineering

Evaluation of aggregates, sand, and cement to ensure compliance with structural specifications and standards.

5. Environmental and Geosciences

Grain size analysis of soils, sediments, and other natural materials to understand geological and environmental processes.

6. Quality Control in Manufacturing

Routine monitoring of raw materials and finished products to maintain consistency, meet regulatory requirements, and reduce batch-to-batch variation.

MtoZ Biolabs' Sieve Analysis Services offer high-quality data and expert interpretation to support product development, quality control, and regulatory compliance. Free project evaluation, welcome to learn more details.

How to order?