Powder Flowability Analysis Service

Powder Flowability Analysis is an essential method for evaluating how powders behave under various conditions. It is widely applied in pharmaceuticals, food science, cosmetics, chemical engineering, and materials research. Powder flowability is influenced by factors including particle size distribution, morphology, density, humidity, temperature, and storage conditions. Systematic characterization therefore requires a multidimensional testing approach.

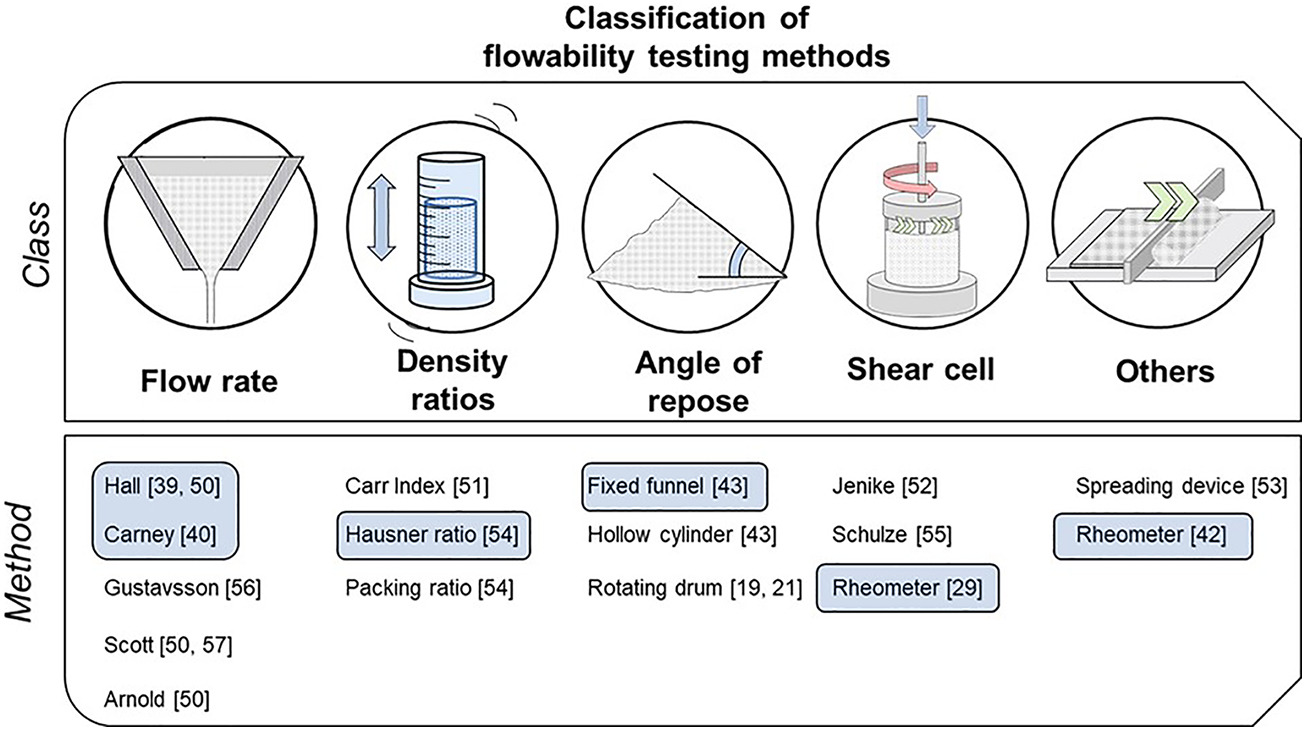

MtoZ Biolabs provides Powder Flowability Analysis Service supported by advanced platforms and an experienced team. Our Powder Flowability Analysis Service integrates classical powder characterization methods with modern rheology. Classical parameters such as Angle of Repose, Bulk Density, Tap Density, and Flow through Orifice describe macroscopic flow properties, while instruments such as the Freeman Technology FT4 Powder Rheometer and Anton Paar MCR Rheometer enable advanced tests including Shear Cell, Wall Friction, and Flow Function analysis to reveal mechanical behaviors under realistic process conditions. The combined solution ensures scientific and reproducible results, providing strong data support for formulation optimization, process improvement, and quality control.

Marchetti, L. et al. Powder Technol. 2021.

Analysis Workflow

1. Sample Reception and Pretreatment: drying, sieving, or humidity adjustment based on project needs.

2. Measurement of Basic Properties: particle size distribution, moisture content, surface area, and bulk density.

3. Condition Control: tests performed under defined temperature and humidity to simulate real production environments.

4. Flowability Evaluation: integrating Shear Cell, Wall Friction, and classical methods for multidimensional analysis.

5. Data Modeling and Comparison: building powder flowability models and comparing across batches.

6. Validation and Reporting: standardized data reports with process optimization recommendations.

Why Choose MtoZ Biolabs?

✔ Multidimensional analysis integrating classical and rheological testing methods

✔ Advanced instrumentation with FT4 and MCR rheometers ensuring data accuracy

✔ Controlled testing environments reflecting actual manufacturing conditions

✔ One-stop service from project design through result interpretation

Sample Submission Suggestions

Powder Flowability Analysis Service accepts a wide range of samples including pharmaceutical raw materials, food additives, cosmetic powders, chemical substances, and environmental materials. Clients are advised to provide detailed information such as sample source, type, concentration range, and buffer composition if relevant. To minimize potential interference, samples containing excessive large particles or strong autofluorescence should be avoided. For powders with hydrophobic properties or aggregation tendencies, our team can provide consultation to establish appropriate experimental conditions. Submitting extra sample quantities is recommended to support repeats and controls, and comprehensive submission guidelines are available upon request.

Applications

· Pharmaceutical development for optimizing tablet compression and capsule filling

· Food engineering for ensuring the flowability and solubility of instant and nutritional powders

· Cosmetics and personal care products for evaluating performance in filling and storage

· Chemicals and functional materials for process adaptability studies

· Agriculture and fertilizers for assessing application uniformity and transport stability

What Could be Included in the Report?

1. Comprehensive experimental details

2. Materials, instruments, and methods

3. Powder flowability parameters report including Angle of Repose and Bulk Density

4. Rheological data and environmental simulation outcomes

5. Data analysis and interpretation report

6. Raw data files

FAQ

Q1: Why combine Shear Cell, Wall Friction, and classical methods?

Because no single method can fully represent powder behavior. Advanced rheology tests reveal flow under stress, while classical methods provide macro-level parameters. Together, these deliver a complete picture that supports scientific research and practical process optimization.

Q2: Can the analysis simulate real production conditions?

Yes. Tests can be conducted under different temperature, humidity, and resting parameters to mimic actual storage and processing. This helps uncover potential risks and provides actionable data for production optimization and quality assurance.

MtoZ Biolabs Powder Flowability Analysis Service combines advanced instrumentation with standardized workflows to deliver accurate and reproducible results. We provide professional data support and solutions that strengthen R&D, improve production stability, and accelerate the translation of findings into industrial practice.

Related Services

How to order?