Iron Nanoparticles Structure Characterization Service | Cryo-EM

Iron nanoparticles structure characterization is a structural analysis based on cryogenic electron microscopy (Cryo-EM), specifically designed to resolve critical information such as the morphological structure, internal architecture, and crystalline orientation of iron nanoparticles. This technique involves rapidly freezing the sample under liquid nitrogen conditions to prevent water crystallization from disrupting the native structure, followed by high-resolution electron beam scanning to achieve nanoscale or even atomic-level imaging and analysis of the iron nanoparticles.

The iron nanoparticles structure characterization service is widely applied in cutting-edge research areas such as materials science, nanocatalysis, biomedicine, and environmental science. It assists researchers in gaining in-depth insights into the structure–property relationships of nanoparticles, mechanisms of magnetic regulation, and their potential applications in drug delivery systems, imaging contrast agents, or environmental remediation materials. The advantages of Cryo-EM, including label-free and low-dose imaging, make it a vital tool for structural studies of iron-based nanomaterials.

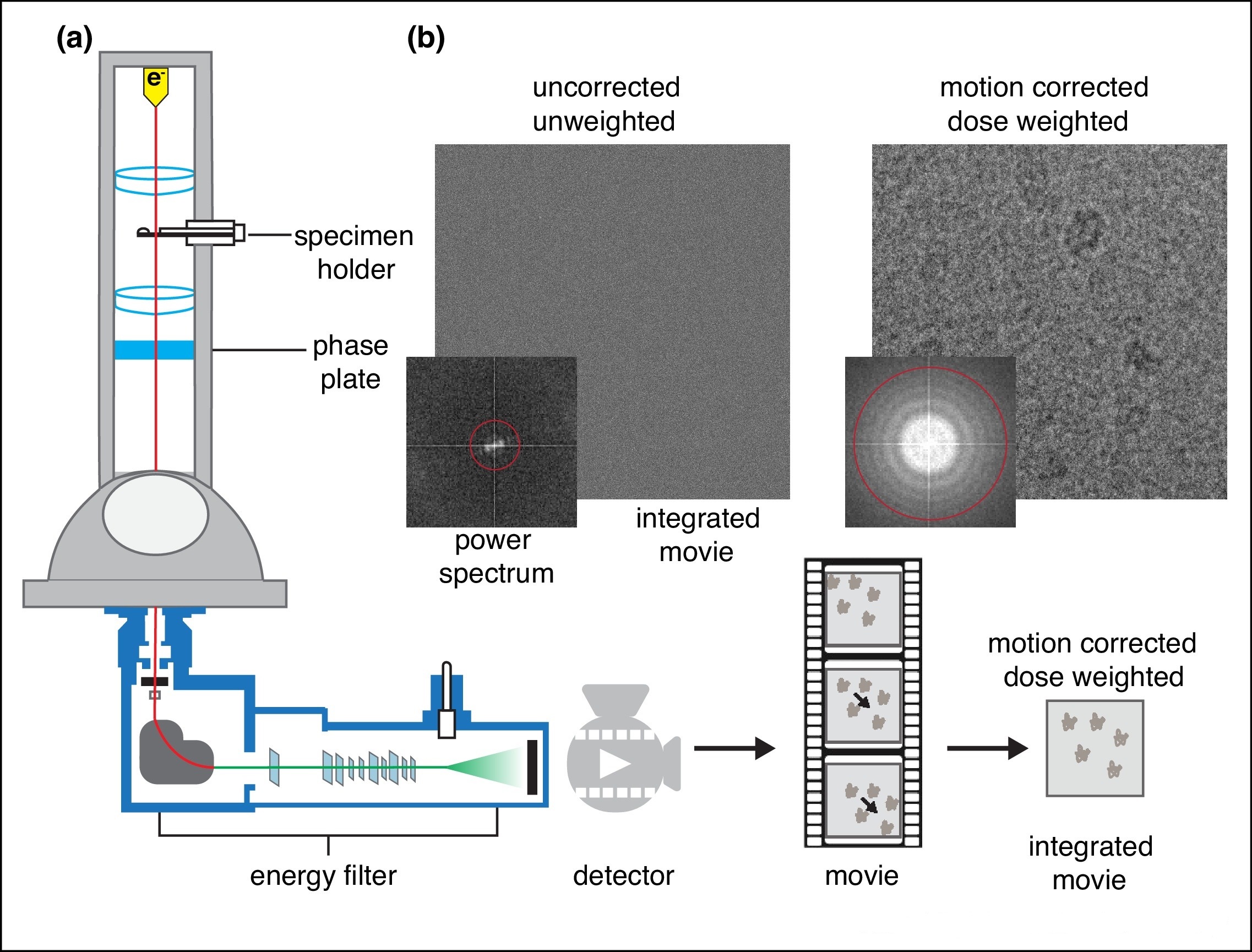

Elmlund, D. et al. Current Opinion in Structural Biology, 2017.

Figure 1. Schematic Illustration of Cryo-EM.

Services at MtoZ Biolabs

Based on an advanced cryogenic electron microscopy platform, the iron nanoparticles structure characterization service based on Cryo-EM offered by MtoZ Biolabs enables rapid vitrification of iron nanoparticles under ultra-low temperature conditions, allowing for high-resolution imaging without staining and under low-dose conditions. This service provides multidimensional information on the morphological structure, particle size distribution, crystalline defects, and interfacial structural features of iron nanoparticles. Through automated data acquisition and image reconstruction, the results retain native-state integrity with nano- to sub-nanometer spatial resolution, making the service ideal for high-precision studies such as nanomaterial performance analysis, catalytic mechanism investigation, and structure–function relationship research.

Analysis Workflow

1. Sample Vitrification

Iron nanoparticles are rapidly cooled to liquid nitrogen temperature to form vitreous ice, preserving their native-state structure.

2. Cryo-EM Image Acquisition

High-resolution, multi-angle images are collected under low-dose conditions using a cryogenic transmission electron microscope to minimize radiation damage.

3. Image Preprocessing and Particle Selection

Images are corrected, denoised, and analyzed for particle recognition, with high-quality particles selected for further analysis.

4. Structural Analysis

The selected particles are analyzed to determine their morphology, lattice structure, and interfacial characteristics.

5. Data and Report Delivery

Raw data, processed images, and a detailed structural analysis report are provided to support scientific publication and in-depth research.

Service Advantages

1. Native-State Cryogenic Imaging

Samples are immobilized under ultra-low temperature conditions to prevent morphological changes caused by conventional drying or staining, preserving the true structure of iron nanoparticles.

2. Sub-Nanometer Resolution

With the support of advanced Cryo-EM platforms such as Titan Krios, this service enables high-resolution imaging and lattice structure observation of iron nanoparticles.

3. Suitable for Heterogeneous Particle Analysis

Capable of identifying and classifying particles of varying morphologies and sizes, allowing parallel analysis of diverse nanostructures.

4. Broad Applicability Across Disciplines

The service supports research in materials science, catalysis, magnetism, and biomedical fields, providing insights into structure–property relationships.

Applications

1. Nanocatalyst Structure Optimization

By analyzing iron nanoparticles, this service reveals surface morphology and lattice defects of iron-based nanocatalysts, contributing to enhanced catalytic activity and stability.

2. Mechanistic Studies of Magnetic Materials

The iron nanoparticles structure characterization service helps uncover the relationship between crystal orientation, magnetic domains, and the overall magnetic behavior of nanoscale materials.

3. Material Design and Functional Control

Structural analysis of iron nanoparticles supports morphology tuning and multiscale structural design of functionalized iron-based materials, driving the development of novel materials.

4. Evaluation of Drug Delivery Carriers

The iron nanoparticles structure characterization service can assess the structural integrity and surface functionality of iron nanoparticles used in drug delivery, providing essential structural insights for nanomedicine research.

5. Characterization of Environmental Remediation Materials

Widely applied in studying the structural evolution and stability of iron-based nanomaterials in pollutant degradation and other environmental applications.

Case Study

1. Synthesis of Polyelectrolyte Nanocapsules with Iron Oxide (Fe₃O₄) Nanoparticles for Magnetic Targeting

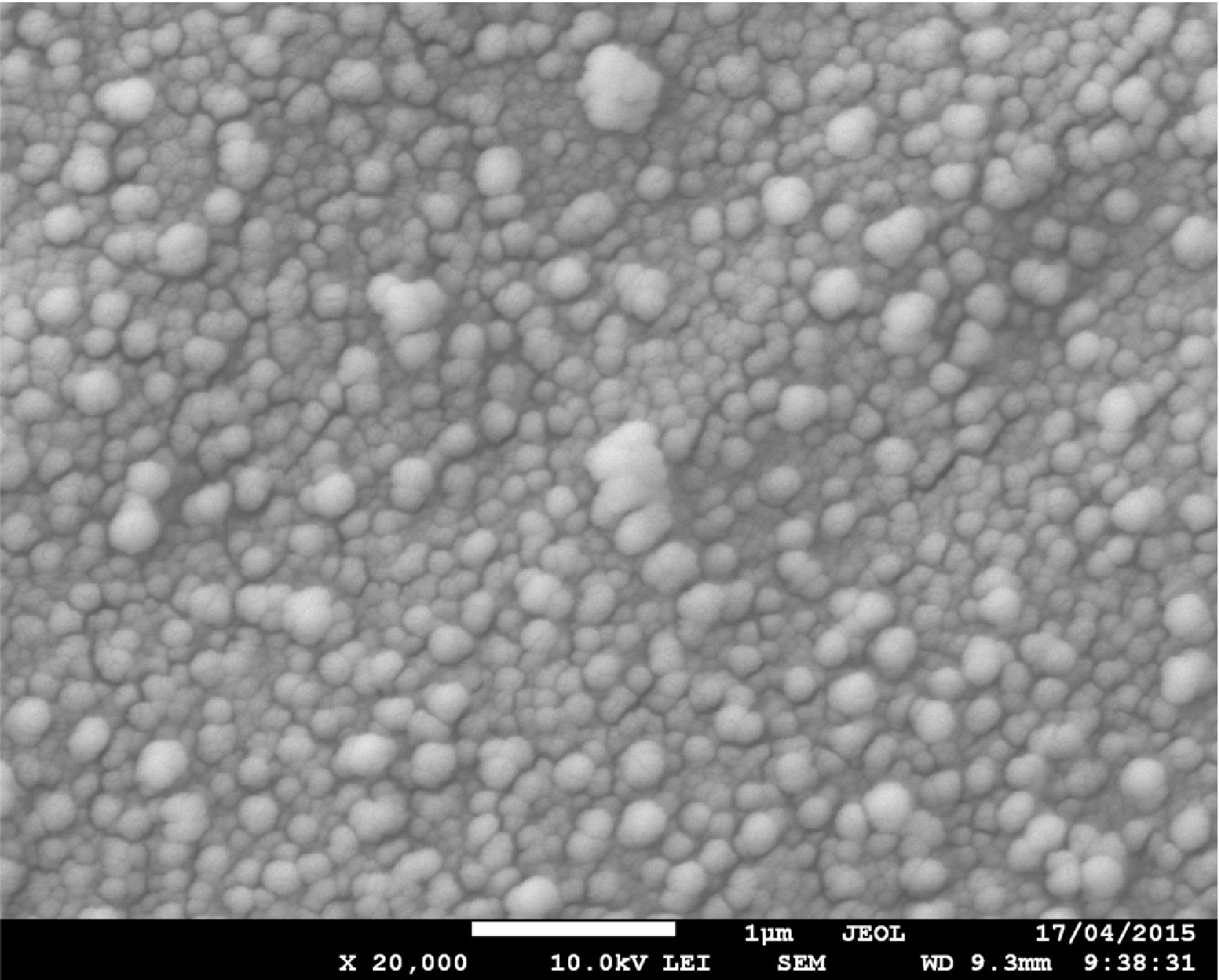

This study aims to develop polyelectrolyte nanocapsules containing iron oxide (Fe₃O₄) nanoparticles for magnetic targeting applications, with a particular focus on structural characterization using cryogenic electron microscopy. The subject of investigation is oil-in-water type capsules embedded with Fe₃O₄ nanoparticles. The authors employed cryogenic scanning electron microscopy (cryo-SEM) to observe the morphology and structural stability of the capsules under near-native low-temperature conditions, and combined this with transmission electron microscopy (TEM) and dynamic light scattering (DLS) to analyze capsule size and nanoparticle distribution. The results showed that Fe₃O₄ nanoparticles were uniformly embedded in the capsule shell, and cryo-SEM clearly demonstrated that the capsules maintained an intact spherical structure under cryogenic conditions, confirming their good colloidal stability and mechanical integrity. The study concludes that cryo-electron microscopy is an effective tool for revealing the microstructure of magnetic nanocapsules and provides structural support and evaluation references for their application in magnetic targeting delivery systems.

Podgórna, K. et al. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2016.

Figure 2. The Example of Cryo-SEM Micrograph of Nanocapsules Core Containing 5 nm Fe3O4 Nanoparticles.

FAQ

Q1: What Are the Advantages of Using Cryo-EM to Analyze Iron Nanoparticles?

A1: Cryo-EM enables in situ imaging under cryogenic conditions, preventing structural changes caused by sample drying. It is particularly suitable for iron nanoparticles whose morphology is sensitive to environmental conditions. With sub-nanometer resolution, Cryo-EM provides accurate information on particle morphology, lattice arrangement, and interfacial features.

Q2: How Does Cryo-EM Differ from Conventional TEM?

A2: Cryo-EM operates at ultra-low temperatures, preserving the native state of samples and avoiding deformation caused by dehydration, making it ideal for environmentally sensitive materials. In contrast, conventional TEM is performed at room temperature and is more suitable for structurally stable materials, but offers lower contrast and reduced accuracy in structural preservation.

How to order?