Electronic Universal Testing Analytical Service

- Material Development: Evaluating new alloys, composites, and polymers.

- Biomedical Engineering: Mechanical testing of implants, scaffolds, and biocompatible materials.

- Automotive and Aerospace: Ensuring mechanical compliance of structural components.

- Construction and Civil Engineering: Assessing strength of building materials such as concrete, steel bars, and fiber-reinforced polymers.

- Product Certification: Verifying mechanical performance as international standards.

- Failure Analysis: Identifying mechanical failure origins post-deformation.

Electronic Universal Testing Analytical Service is a comprehensive analytical solution designed to evaluate the mechanical performance of materials through standardized deformation tests. The Electronic Universal Testing Analytical Service plays a critical role in understanding how materials behave under various mechanical stresses, enabling precise characterization for applications in product development, quality control, failure analysis, and materials research. At the core of this service is the electronic universal testing machine, a versatile instrument capable of performing tensile, compressive, flexural (bending), and shear tests under controlled conditions. This machine applies uniaxial forces to the specimen while precisely recording stress-strain responses, providing essential data such as yield strength, modulus of elasticity, breaking point, and deformation behavior.

Technical Principles

The electronic universal testing machine operates by using motorized actuators to apply force through grips or fixtures while capturing real-time load and displacement data via integrated sensors. Depending on the test type, materials are either pulled, compressed, bent, or sheared until failure or a predefined limit is reached. The resulting mechanical profiles are critical for validating structural integrity and performance reliability.

Service at MtoZ Biolabs

MtoZ Biolabs provides high-precision Electronic Universal Testing Analytical Services for a wide spectrum of material types. Our platform supports a full range of mechanical tests, including tensile, compression, bending, and shear experiments for both metallic and non-metallic samples. For non-metallic bulk materials, we conduct three parallel tests to ensure data consistency and reproducibility. Leveraging advanced testing instruments and standardized analytical workflows, MtoZ Biolabs offers reliable, reproducible, and publication-ready mechanical testing data to support your research, development, and compliance needs. Whether you are evaluating structural polymers, metals, ceramics, or novel composites, our service delivers insights critical to engineering success.

Analysis Workflow

At MtoZ Biolabs, each Electronic Universal Testing Analytical Service project undergoes a streamlined, quality-controlled analytical process designed for accuracy, consistency, and relevance to customer objectives.

1. Sample Submission & Consultation

Clients submit samples with designated test parameters and application requirements. Our team provides technical consultation and test plan development.

2. Specimen Preparation

Samples are cut, shaped, and conditioned based on the target material class. For non-metallic bulk specimens, we can test three parallel samples to ensure data reproducibility.

3. Instrument Configuration

The appropriate testing fixtures (tensile, compression, bending, shear) are mounted on the electronic universal testing machine. Load capacity, displacement limits, and testing speed are configured.

4. Testing Execution

Tests are carried out using our high-precision electronic universal testing machines. Real-time data acquisition ensures detailed mechanical response curves.

5. Data Analysis and Reporting

Raw data is processed into standardized mechanical property reports. Plots, key metrics, failure modes, and comparative insights are included.

Service Advantages

✔️Broad Testing Capability: Applicable to metals, ceramics, plastics, elastomers, composites, and biomaterials.

✔️Data Quality Assurance: Each test is run under standard operating procedures and reviewed by mechanical testing experts.

✔️Fast Turnaround: Efficient sample handling and streamlined reporting for academic and industrial timelines.

✔️Custom Protocol Design: Flexible test parameters and report formats tailored to client-specific needs.

Applications

The Electronic Universal Testing Analytical Service is critical across industries and research disciplines. Typical applications include:

Case Study

Mechanical Characterization of CSC/Epoxy Resin Composites

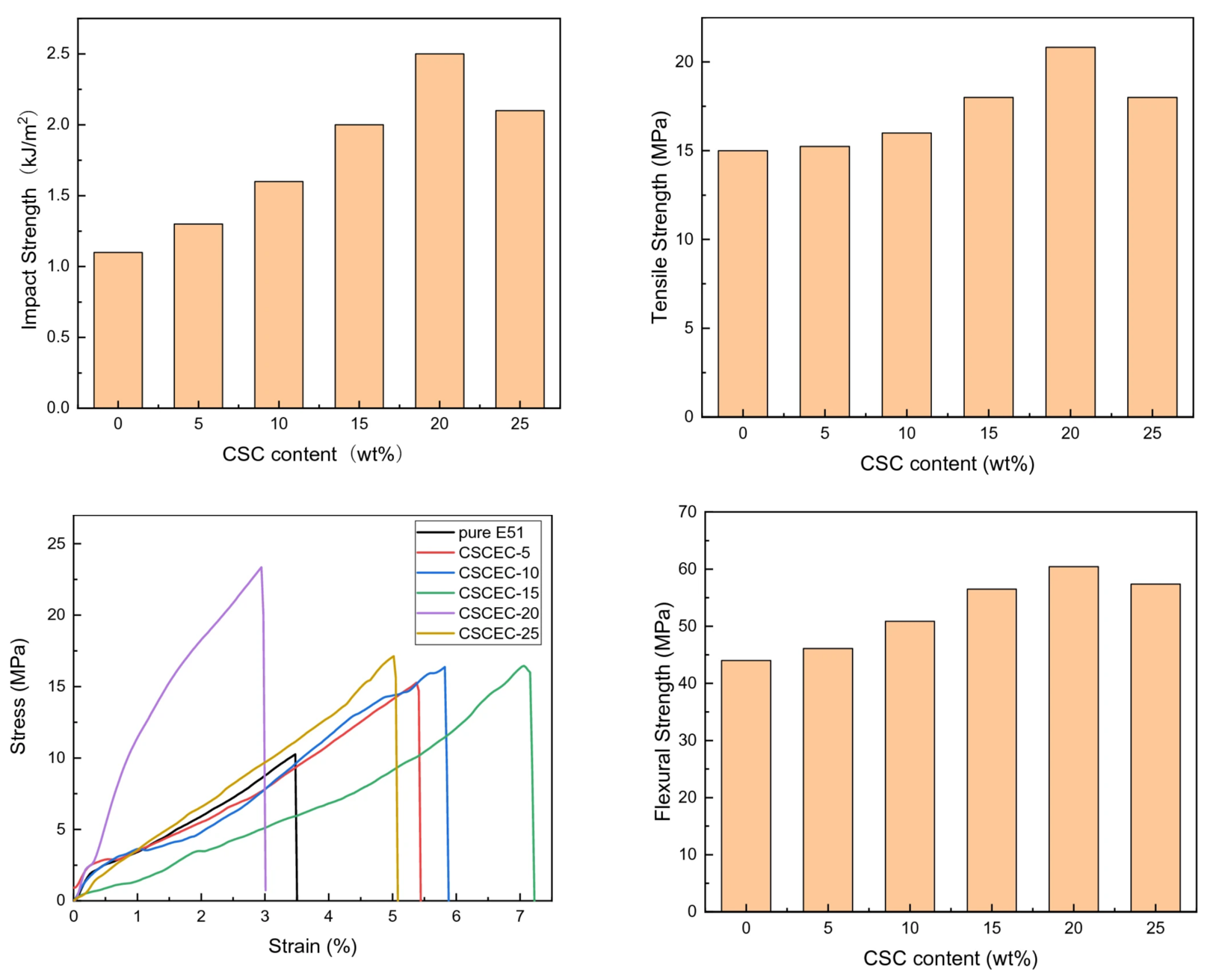

To investigate the mechanical enhancement effect of corn-stalk cellulose (CSC) on epoxy resin, a series of CSC/epoxy resin composites were subjected to tensile, flexural, and impact testing using electronic universal testing machines. At a CSC content of 20 wt%, the composites exhibited optimal performance: tensile strength increased by 37.5% (from 15.14 MPa to 20.82 MPa), flexural strength rose by 36.9% (to 60.43 MPa), and impact strength reached 2.50 kJ/m², 127.2% higher than that of pure epoxy resin. The improvements were attributed to uniform CSC dispersion and effective stress transfer. However, excessive CSC caused agglomeration, reducing performance. This case highlights how Electronic Universal Testing Analytical Service enables precise quantification of mechanical property changes in modified materials, providing essential support for composite formulation and performance evaluation.

Figure 1. Impact Strength Drawing, Tensile Strength Drawing, Tensile Stress–Strain Curves, and Flexural Strength Drawing of the Composites

Electronic universal testing machine is an indispensable tool for quantifying the mechanical behavior of materials under real-world conditions. With MtoZ Biolabs as your analytical partner, you gain access to comprehensive, standards-compliant, and research-grade testing services that support innovation, safety, and performance. Contact us today to learn how our Electronic Universal Testing Analytical Service can advance your materials research, product development, and quality control initiatives.

How to order?