Dynamic Mechanical Analysis (DMA) Testing Service

- Tensile Mode: For films and fibers

- Bending (3-point or dual cantilever): For rigid plastics and composites

- Shear or Torsion Mode: For soft solids, rubbers, and adhesives

- Compression Mode: For foams and bulk samples

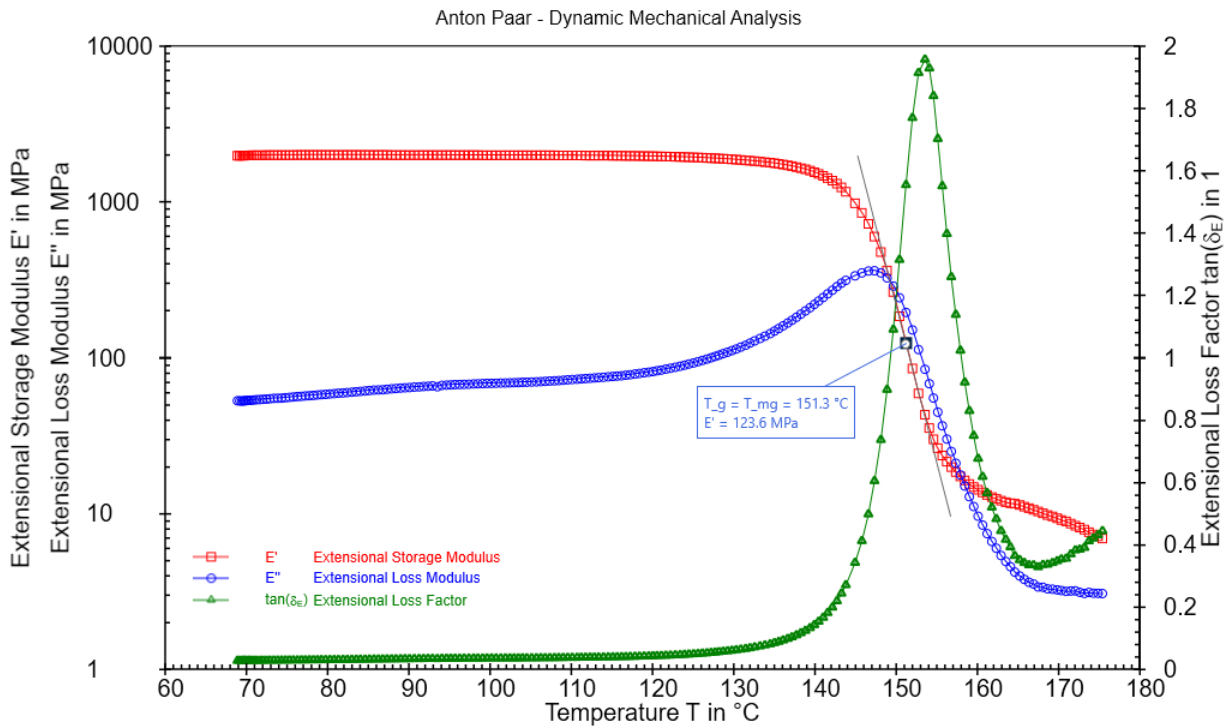

- Temperature sweep: Detects transitions like glass transition temperature (Tg), crystallization, and softening points

- Frequency sweep: Evaluates material behavior under different deformation rates

- Time sweep: Tracks properties under constant stress/strain over time

- Stress/strain sweep: Assesses linear viscoelastic range and yield behavior

Dynamic Mechanical Analysis (DMA) Testing is a fundamental analytical technique used to characterize the viscoelastic behavior of materials under dynamic loading conditions. Dynamic Mechanical Analysis (DMA) Testing provides quantitative insight into how materials respond to stress, strain, frequency, temperature, and time, making it essential for optimizing the mechanical performance of polymers, composites, elastomers, biomaterials, coatings, and advanced functional materials. Recognizing the critical role of DMA in modern materials evaluation, MtoZ Biolabs now offers specialized Dynamic Mechanical Analysis (DMA) Testing Service tailored to a wide range of research and industrial applications.

In dynamic mechanical analysis (DMA) testing, a sinusoidal mechanical force is applied to a sample, and its resulting deformation (strain) is measured. By analyzing the phase difference between stress and strain, the technique yields precise information on storage modulus (elastic response), loss modulus (viscous response), and damping factor (tan δ)—key parameters for evaluating stiffness, energy dissipation, and temperature-dependent mechanical transitions.

Figure 1. Typical DMA Thermogram of an Amorphous Thermoplastic (Polycarbonate)

Dynamic mechanical analysis (DMA) testing provides deep insight into molecular mobility, crosslinking, transition points, and fatigue resistance, which are crucial for predicting material performance under real-world conditions such as vibration, impact, and thermal cycling. Dynamic mechanical analysis (DMA) testing is widely used in material development, quality control, failure analysis, and structure-property relationship studies, offering unmatched sensitivity to molecular motions and phase transitions.

Technical Principles

The core principle of Dynamic Mechanical Analysis (DMA) Testing Service is based on applying a dynamic, oscillatory force to a material and measuring its deformation. The sample's response provides real-time information on its mechanical modulus and damping behavior. The technique operates in one of several deformation modes, depending on the sample geometry and material type:

DMA measurements can be performed under various test profiles, with outputs typically analyzed as a function of key parameters such as temperature, frequency, force, displacement, and modulus. Common test modes include:

Service at MtoZ Biolabs

MtoZ Biolabs offers high-precision Dynamic Mechanical Analysis (DMA) Testing Service for a wide range of viscoelastic materials, including polymers, elastomers, and rubber-based composites. Our Dynamic Mechanical Analysis (DMA) Testing Service provides comprehensive measurement of storage modulus (E'), loss modulus (E''), viscoelastic behavior, creep and stress relaxation, and glass transition temperature (Tg) under controlled dynamic loading conditions. Whether you are studying thermoplastic blends, crosslinked rubbers, or advanced functional materials, MtoZ Biolabs supports your research with accurate, reproducible, and publication-ready results tailored to design optimization and structure–property analysis. If you are interested in our Dynamic Mechanical Analysis (DMA) Testing Service, please feel free to contact us. Our technical specialists are available to provide a free business assessment.

Analysis Workflow

1. Sample Preparation

Samples are cut or molded into standardized shapes based on test mode requirements, ensuring appropriate geometry and surface quality.

2. Mode and Fixture Selection

The appropriate deformation mode (tension, bending, compression, or shear) and fixture type are selected according to material type and stiffness.

3. Test Parameter Configuration

Temperature range, frequency range, strain amplitude, and ramp rates are defined based on the analysis goal and material behavior.

4. DMA Testing Execution

The sample is subjected to controlled oscillatory loading under programmed conditions, and real-time modulus and damping data are collected.

5. Data Processing and Analysis

Storage modulus, loss modulus, tan δ, and transition points are extracted and plotted against temperature, frequency, or time.

6. Report Delivery

A detailed report including raw data, interpretation, graphs, and key mechanical property values is delivered, with optional consultation for further insights.

Service Advantages

✔️Covers wide temperature, frequency, force, and modulus ranges.

✔️Supports multiple deformation modes including tension, bending, shear, and compression.

✔️Offers fully customizable test protocols based on sample type and objectives.

✔️Provides high-resolution, publication-ready data with expert interpretation.

✔️Ensures reliable, reproducible results through strict quality control.

Applications

💠Polymer and Composite Development: Evaluate viscoelastic properties, Tg, and relaxation behavior for material design and formulation optimization.

💠Rubber and Elastomer Testing: Analyze damping capacity, fatigue resistance, and dynamic modulus for sealing, vibration, and impact applications.

💠Biomedical Materials: Characterize hydrogels, scaffolds, and implantable polymers under physiological temperature and frequency conditions.

💠Adhesives and Coatings: Assess curing behavior, bonding strength, and mechanical stability over thermal cycles.

💠Foams and Packaging Materials: Measure compression modulus, recovery behavior, and long-term mechanical reliability.

Case Study

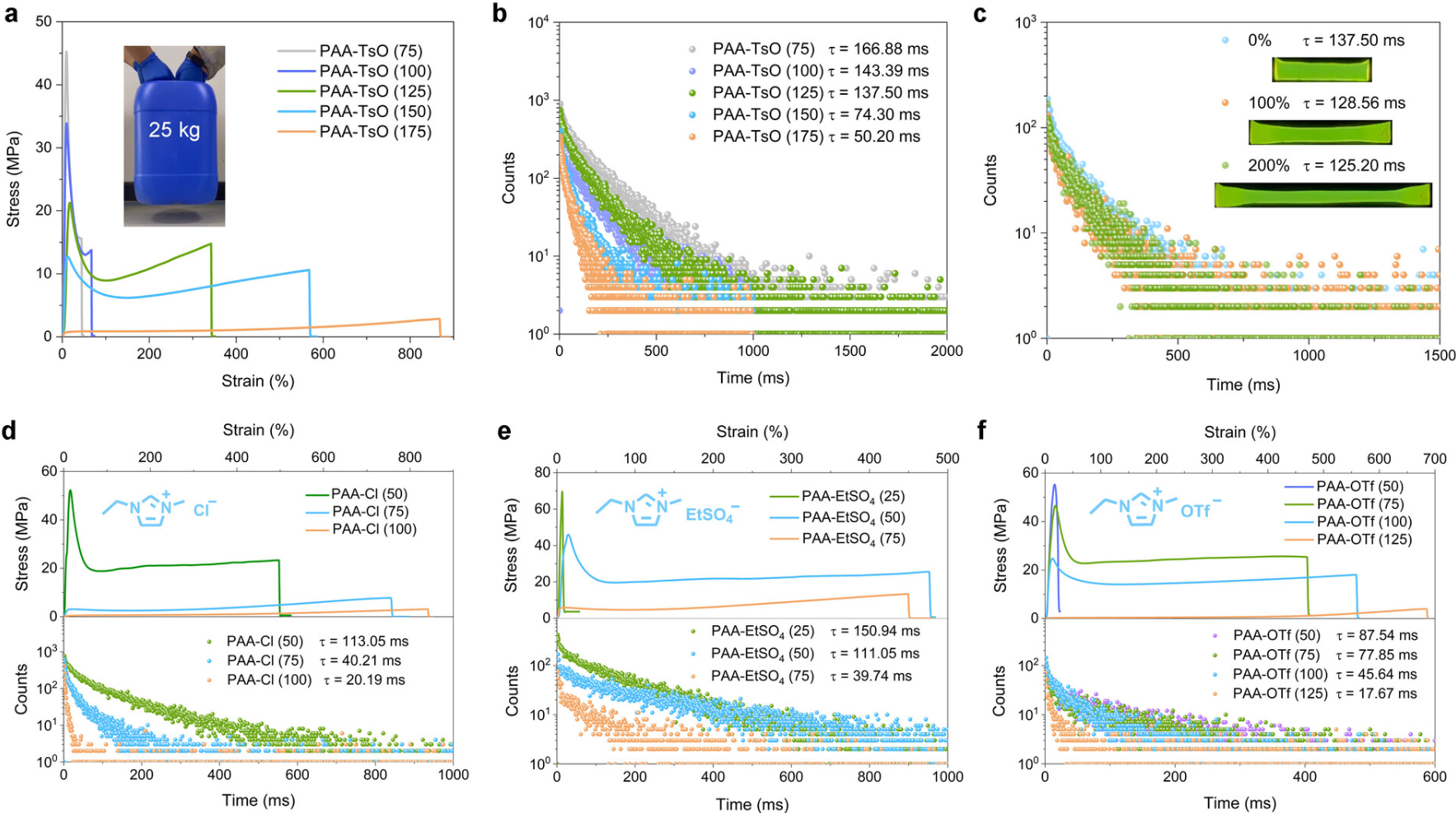

Revealing Mechanics–Photophysics Correlation in RTP Ionogels Using DMA

A recent study on room-temperature phosphorescence (RTP) ionogels used Dynamic Mechanical Analysis (DMA) to reveal how viscoelastic properties correlate with photophysical performance. By analyzing glass transition temperature (Tg) and loss modulus peak temperature (Tloss), researchers classified ionogels into distinct mechanical-phosphorescence regimes: tough with persistent glow, stretchable with efficient emission, and resilient with reduced intensity. This approach enabled accurate prediction of RTP performance without repeated synthesis and optical testing. The study demonstrates how DMA can serve as a powerful tool to connect molecular dynamics with material performance, accelerating the development of functional materials. MtoZ Biolabs offers high-resolution dynamic mechanical analysis (DMA) testing to support such applications, providing critical insight into structure–property relationships in polymers, elastomers, and smart materials.

Figure 2. Mechanical and Photophysical Properties of RTP Homopolymer Ionogels

How to order?