Dual Beam Focused Ion Beam(FIB)Analytical Service

Dual beam focused ion beam (FIB) is an advanced microscopy tool that integrates a focused ion beam with a scanning electron microscope (SEM). It can cut into samples with the ion beam, acting like a “microsurgical knife,” while simultaneously imaging the structures with the electron beam, similar to a “high-magnification microscope.” This technology allows researchers to visualize not only surface details but also the hidden layers and interfaces inside samples. In pharmaceutical research, the uniformity of tablet coatings and the binding between drug and excipients directly affect drug efficacy and release profiles. In materials and biomedical studies, the density of coatings and the quality of material interfaces often determine stability and performance. Based on a well-established Dual Beam FIB platform, MtoZ Biolabs provides a reliable dual beam focused ion beam(FIB)analytical service for pharmaceutical, materials science, and life science research.

Technical Principle

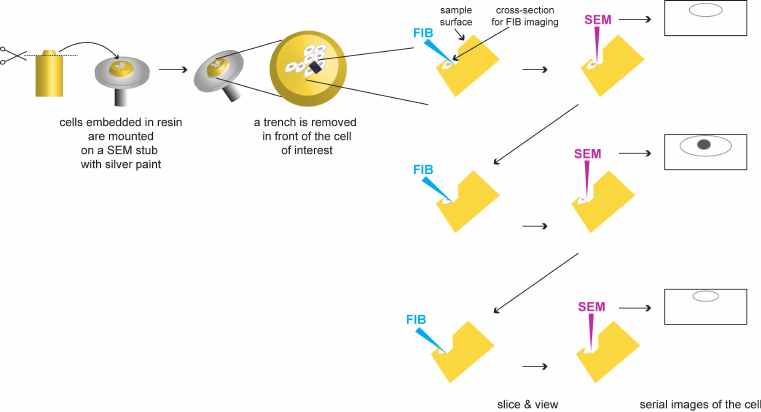

The basic principle of dual beam FIB can be simply understood as follows: a beam of charged ions “sculpts” the sample surface by cutting away a very thin layer of material in a controlled area, while an electron beam simultaneously captures real-time images of the exposed cross-section or processed structure. The high-energy ion beam enables precise removal of nanoscale material, revealing internal structures, and the electron beam ensures accurate imaging during the process. Together, they allow researchers to cut and observe at the nanoscale—like having both a fine surgical knife and a high-resolution microscope at the same time.

Romero-Brey, I. et al. Viruses. 2015.

Figure 1. The principle of Dual Beam Focused Ion Beam

Services at MtoZ Biolabs

With the dual beam FIB platform, MtoZ Biolabs offers a wide range of dual beam focused ion beam(FIB)analytical services tailored to different research needs:

1. Cross-Section Preparation Service: Opening a window on the sample surface with the ion beam to produce a smooth cross-section for studying tablet coatings, polymer films, and composite material interfaces. Researchers can directly observe layer thickness, uniformity, cracks, or pores.

2. Nano-Fabrication Service: Performing fine micro- and nanoscale processing, such as making alignment marks, micro-holes, or channels. This is often used for pre-experimental sample marking or for studying material behavior at very small scales.

3. Microstructural Analysis Service: Combining FIB with SEM for detailed observation and analysis of micro-areas, suitable for investigating coating–substrate adhesion, biomaterial–tissue interfaces, and layered structures in electronic devices.

4. Additional Services: Beyond routine analysis, MtoZ Biolabs provides advanced processing and characterization, such as preparing ultra-thin lamellae for transmission electron microscopy (TEM) or performing 3D reconstruction by sequential slicing and imaging. Elemental mapping or defect visualization can also be conducted, offering a more comprehensive understanding of sample properties.

Analysis Workflow

1. Confirm analysis requirements and feasibility.

2. Mount and secure the sample, apply protective layers if needed.

3. Use the ion beam to cut the target area while imaging with the electron beam.

4. Choose cross-sectioning, nano-fabrication, or 3D reconstruction depending on project needs.

5. Collect images and data, process and analyze results.

6. Deliver reports and datasets to the client.

Service Advantages

1. Project-Oriented Customization

MtoZ Biolabs does not provide standardized, one-size-fits-all procedures. Instead, we design a tailored dual beam focused ion beam(FIB)analytical service based on the client’s research goals. Whether for cross-sectioning of tablet coatings or studying biomaterial interfaces, we work with clients during the planning stage to identify the most suitable approach.

2. Transparent Process and Results

Clients are informed of each step of the service process and its purpose. Delivered reports not only include results but also key procedural details and data sources, ensuring researchers can confidently use the outcomes for scientific studies or quality assessments.

3. Expert Technical Support

Our team consists of professionals with extensive experience in microscopy and materials research. They understand the characteristics and limitations of various samples and carefully adjust operating conditions to minimize damage or bias, ensuring reliable results.

4. Broad Applications

Our dual beam focused ion beam(FIB)analytical service covers pharmaceutical solids, coating materials, polymers, metals, ceramics, and biomedical materials, supporting research across pharmaceuticals, materials science, and biology.

5. Efficient Data Delivery

Reports and data are organized in a structured format, with images labeled with scales and annotations. Files are delivered in formats suitable for immediate use in research, regulatory submissions, or internal reporting.

Applications

☑️Pharmaceutical Research: Examine tablet cross-sections and evaluate coating thickness and uniformity.

☑️Coating Studies: Assess coating–substrate adhesion and identify cracks or pores.

☑️Biomaterials: Investigate the interface between implants or bio-coatings and tissues.

☑️Electronics and Microdevices: Analyze layered structures and defects in chips and sensors.

FAQs

Q1: Does FIB damage the sample?

FIB removes material in localized areas, causing small-scale damage, but the overall sample remains intact.

Q2: Can elemental information be obtained simultaneously?

Yes, elemental analysis can be performed with energy-dispersive X-ray spectroscopy (EDS) to support structural interpretation.

Sample Submission Suggestions

1. Provide clean, dry samples to avoid contamination.

2. Mark or describe the target region for precise positioning.

3. Notify us in advance of special or sensitive samples to ensure proper handling.

4. Powders must be fixed or embedded to prevent scattering in vacuum conditions.

Deliverables

1. Image Data: High-resolution cross-section images, processed structures, or 3D reconstructions.

2. Analysis Report: Includes procedures, results, conclusions, and explanations.

3. Data Files: Raw images and processed files for reuse and archiving.

Dual beam FIB is a powerful tool capable of “cutting” and observing samples at the nanoscale, revealing hidden structural details in pharmaceuticals, materials, and biological specimens. MtoZ Biolabs transforms this technology into a dual beam focused ion beam(FIB)analytical service designed for both research and industry, helping clients obtain reliable structural insights efficiently.

Contact MtoZ Biolabs today to discuss your project needs. We will provide you with a customized dual beam FIB analysis solution.

How to order?