XRF Testing Service

X-ray Fluorescence (XRF) testing is an elemental analysis method based on X-ray fluorescence spectroscopy, used for rapid and non-destructive detection of the elemental composition and concentration in a sample. The fundamental principle involves using high-energy X-rays to excite atoms within the sample, causing them to emit characteristic secondary X-rays (fluorescent X-rays). By detecting these characteristic signals, the types and concentrations of elements in the sample can be identified and quantified. XRF testing requires no sample pretreatment and is applicable to various material forms including solids, powders, and liquids.

XRF testing service is widely used in fields such as materials science, environmental monitoring, metal smelting, building material analysis, electronics, geological exploration, and cultural relic identification. It is particularly suitable for heavy metal detection, RoHS/ELV compliance testing, coating thickness analysis, and multi-element quantitative screening. Due to its ease of operation, rapid response, and minimal sample damage, XRF testing holds significant practical value in both scientific research and industrial applications.

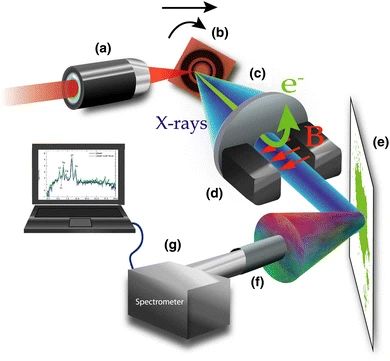

Brozas, F V. et al. Applied Physics B, 2016.

Figure 1. Experimental Setup of X-ray Fluorescence Spectrometer.

Services at MtoZ Biolabs

Based on a high-performance XRF spectrometer platform, the XRF testing service provided by MtoZ Biolabs enables rapid, non-destructive analysis of metallic and non-metallic elements in solid, powder, and liquid samples. Utilizing either Energy Dispersive X-ray Fluorescence (EDXRF) or Wavelength Dispersive X-ray Fluorescence (WDXRF) technology, the service supports qualitative and semi-quantitative analysis of elemental content, covering a wide range of elements from sodium (Na) to uranium (U). This service ensures stable and reproducible data, making it suitable for material composition analysis, elemental screening, and quality control applications. XRF testing can be categorized into the following modes based on the analytical objectives and sample types:

1. Elemental Form Mode

This mode is used to directly detect the intrinsic content of each element in the sample and is commonly applied in the elemental composition analysis of metal alloys, raw ores, and similar materials. The results are reported as mass percentages of individual elements, making it suitable for research or industrial scenarios that require accurate determination of actual metal or elemental content.

2. Oxide Form Mode

This mode is applicable to the compositional analysis of inorganic materials such as geological samples, ceramics, cement, and glass. The results are presented in the form of corresponding oxides, such as SiO₂, Al₂O₃, and Fe₂O₃, which facilitates material quality evaluation, formula optimization, and comparison with industry standards.

Service Advantages

1. Non-Destructive Testing

XRF technology does not require acid digestion or high-temperature treatment during analysis, ensuring that the sample remains intact. This makes it ideal for repeat testing and follow-up analysis of valuable or limited samples.

2. Rapid Analytical Response

The testing process requires no complex sample preparation, and elemental composition data can be obtained within minutes. This is especially suitable for rapid screening and comparison of large numbers of samples, significantly improving experimental efficiency.

3. Broad Applicability

XRF can detect a wide range of elements from sodium (Na) to uranium (U), making it suitable for qualitative and quantitative analysis of complex matrix samples such as metals, alloys, minerals, soil, building materials, and ceramics.

4. High Data Reproducibility

Utilizing high-precision XRF instruments combined with rigorous standard curve calibration and quality control systems ensures highly consistent results and reliable data across tests.

5. Flexible Testing Modes

Supports both elemental form and oxide form analysis, allowing selection of the appropriate mode based on research objectives. This flexibility makes XRF widely applicable in material development, geological exploration, environmental monitoring, and quality control across various industries.

Applications

1. Material Composition Identification

XRF testing service is widely used for analyzing the elemental composition of metals, alloys, glass, ceramics, and other materials. It helps verify whether products meet formulation standards or process specifications, making it suitable for both research and quality control applications.

2. Geological and Mineral Analysis

By enabling rapid screening and quantification of major and trace elements in rocks, ores, and soil samples, XRF is commonly applied in geological exploration, mineral resource evaluation, and environmental geochemical studies.

3. Environmental Pollution Monitoring

XRF testing service is ideal for non-destructive detection of heavy metal pollutants such as Pb, Cd, Hg, and As in samples like soil, dust, and sediments. It supports pollution source tracing and environmental risk assessment.

4. Industrial Process Monitoring

By conducting intermediate products, recycled materials, or waste generated during industrial processes. This supports factories in regulating material composition, optimizing cost control, and promoting sustainable manufacturing practices.

Case Study

1. Elemental Analysis of Aquatic Plants by X-ray Fluorescence

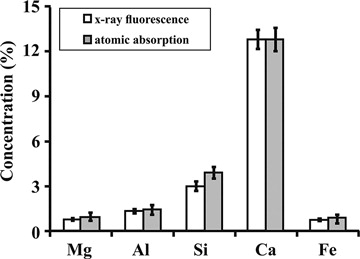

This study aimed to evaluate the feasibility and accuracy of X-ray fluorescence spectroscopy (XRF) in the elemental analysis of aquatic plants. The subjects were various freshwater plant samples. A portable XRF instrument was used to directly analyze dried and ground plant samples, and the results were compared with those obtained using traditional ICP-OES (Inductively Coupled Plasma Optical Emission Spectrometry) for validation. The findings showed that XRF could rapidly detect a variety of common elements, including K, Ca, Fe, Mn, and Zn, without the need for chemical digestion. The results were highly consistent with those from ICP-OES, especially in the medium to high concentration range. The study concluded that XRF is a fast, non-destructive, and cost-effective method for elemental analysis of aquatic plants. It is suitable for environmental monitoring and plant nutrition studies, particularly in field screening and large-scale survey scenarios.

Chuparina, E V. et al. Analytical Letters, 2016.

Figure 2. Determination of Common Elements in Aquatic Plants by X-ray Fluorescence and Atomic Absorption Spectroscopy.

FAQ

Q1: How Accurate Are XRF Test Results? Can they Be Used for Quantitative Analysis?

A1: XRF offers good repeatability and relative quantification capabilities, especially for elements present at medium to high concentrations. However, for trace elements, it is recommended to validate results using complementary methods such as ICP-MS.

Q2: Can I Choose Between Elemental form Mode and Oxide form Mode? What Is the Difference?

A2: Yes, you can. Elemental form mode reports the mass percentage of individual elements and is commonly used for metallic materials such as alloys. Oxide form mode reports element concentrations in the form of their corresponding oxides (e.g., SiO₂, Al₂O₃), which is suitable for non-metallic samples such as geological, building, or mineral materials.

Q3: Is Batch Testing of Multiple Samples Supported?

A3: Yes. We support batch sample analysis and can perform standardized preparation and reporting based on sample characteristics. This is ideal for research projects, process evaluations, and routine production testing.

MtoZ Biolabs, an integrated chromatography and mass spectrometry (MS) services provider.

Related Services

Structure&Component Analysis Services

Organic Element Analyzer (EA) Analytical Service

How to order?