Thermogravimetric-infrared (TG-IR) Analytical Service

Thermogravimetric-infrared (TG-IR) analysis is a hyphenated analytical technique that integrates thermogravimetric analysis (TG) with infrared spectroscopy (IR), aiming to simultaneously monitor mass changes of materials during heating and identify the infrared absorption characteristics of the evolved gases. The principle involves recording the sample’s mass loss curve under programmed temperature conditions using TG, while the gases released during thermal decomposition are transferred in real time through a heated transfer line into the IR spectrometer. There, characteristic functional groups in the gas molecules are analyzed to infer their chemical composition.

Thermogravimetric-infrared (TG-IR) analytical service is widely applied in evaluating the thermal stability of polymeric materials, analyzing decomposition products of additives or flame retardants, studying pyrolysis behaviors of environmental solid waste or biomass, and characterizing the thermal degradation of pharmaceuticals or fine chemicals. This technique offers advantages such as non-destructive analysis, high sensitivity, and complementary information output, making it a powerful tool for understanding the thermal behavior and chemical nature of volatile products. It is suitable for research in materials science, chemical engineering, environmental analysis, and related fields.

Services at MtoZ Biolabs

Based on a hyphenated platform integrating a thermogravimetric analyzer (TG) and an infrared spectrometer (IR), the thermogravimetric-infrared (TG-IR) analytical service provided by MtoZ Biolabs enables simultaneous acquisition and analysis of sample mass changes and evolved gas composition. During controlled-atmosphere heating, TG continuously records the mass loss of the sample as a function of temperature, while the gases released during decomposition are transferred through a heated line into the IR spectrometer for molecular characterization. This service provides both thermal stability profiles and qualitative identification of volatile gases through infrared functional group analysis, supporting comprehensive insights into thermal behavior, material safety evaluation, and decomposition mechanism research.

Analysis Workflow

1. Sample Preparation and Weighing

Accurately weigh the target sample and place it into the crucible of the thermogravimetric analyzer (TG), ensuring sample uniformity and freedom from contamination.

2. Thermogravimetric Analysis (TG)

Heat the sample under controlled temperature ramping and atmospheric conditions, recording the mass loss curve as a function of temperature to reflect thermal decomposition behavior and stability.

3. Gas Transfer

Volatile products released during sample decomposition are transferred in real time to the infrared gas analyzer (IR) via a heated gas transmission line.

4. Infrared Spectral Detection (IR)

The IR gas analyzer identifies functional groups in the transferred gases, acquiring absorption spectra and analyzing the types and release trends of gaseous components.

5. Data Integration and Interpretation

Synchronously analyze the TG thermal data and IR gas identification information to comprehensively reveal the sample’s pyrolysis stages, volatile release pathways, and compositional changes.

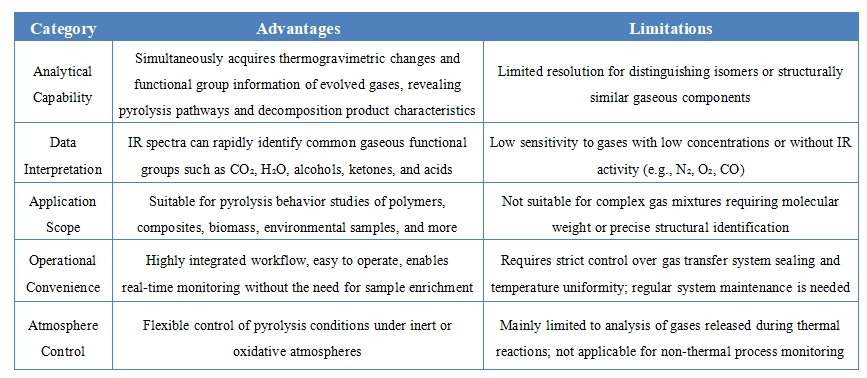

Advantages and Limitations

Applications

1. Thermal Stability Assessment of Polymer Materials

Thermogravimetric-infrared (TG-IR) analytical service can be used to analyze mass changes and gas release behavior of polymers such as plastics, rubbers, and fibers during heating, in order to evaluate their thermal stability and degradation mechanisms.

2. Mechanistic Study of Flame Retardants and Additives

By detecting characteristic functional groups of gases released during thermal decomposition, this service reveals the decomposition features and reaction pathways of functional additives such as flame retardants and antioxidants at different temperatures.

3. Resource Utilization Analysis of Biomass and Waste Materials

Thermogravimetric-infrared (TG-IR) analytical service can be applied to investigate the composition of volatile products during the thermal treatment of biomass and solid waste, providing data support for thermal conversion, gasification, and pollution control.

4. Pollutant Screening and Source Tracing in Environmental Samples

By thermally desorbing and infrared-identifying organic components in contaminated soils, microplastics, or industrial residues, this service aids in pollutant composition analysis and source attribution.

5. Failure Analysis and Aging Behavior of Materials

Thermogravimetric-infrared (TG-IR) analytical service can be used to evaluate the decomposition characteristics of composite materials, coatings, and sealing materials during high-temperature aging, supporting the design of product durability and reliability.

Case Study

1. Thermogravimetric-Infrared Analysis and Performance Optimization of Co-Pyrolysis of Oily Sludge and Rice Husks

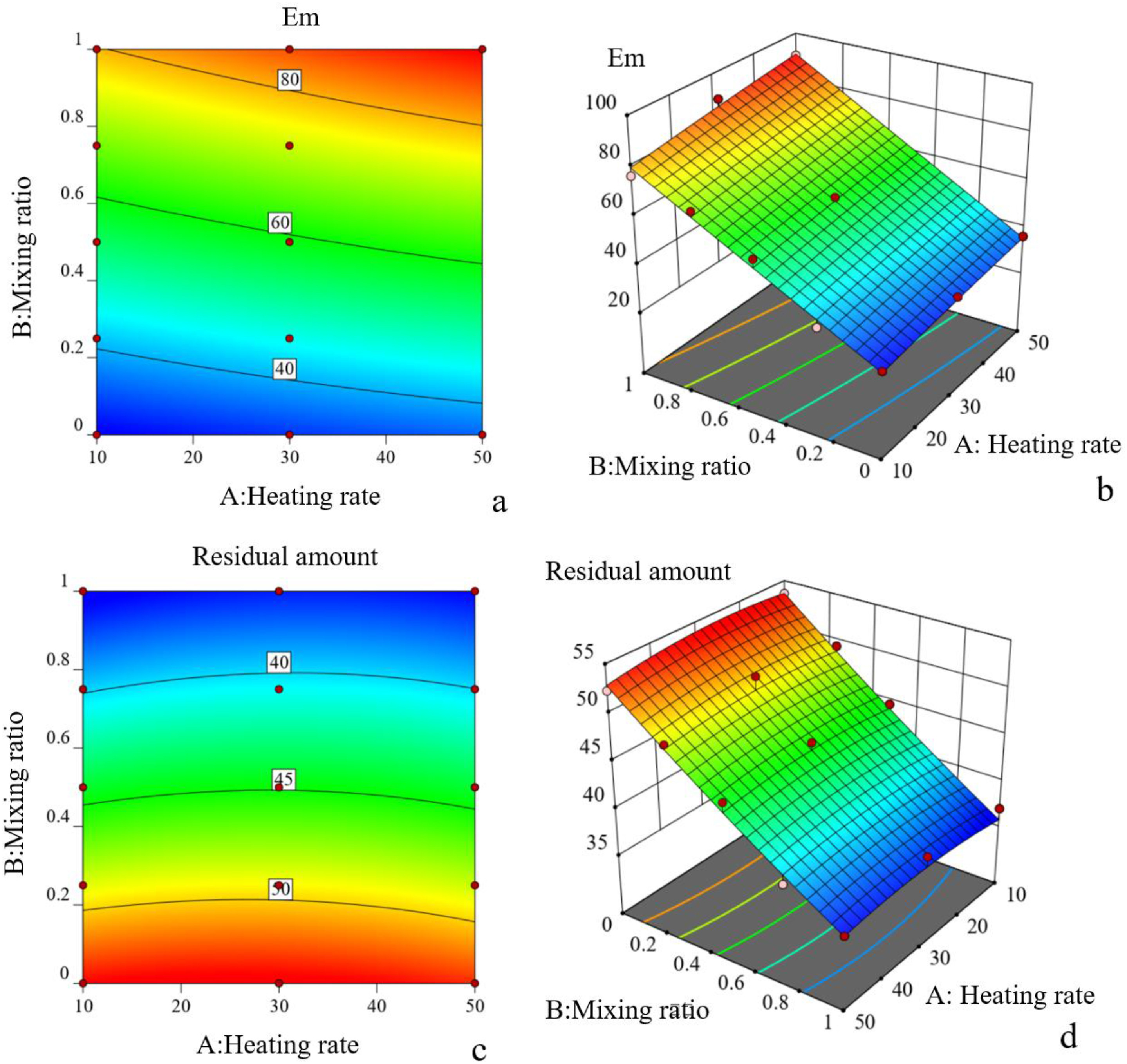

This study aimed to investigate the thermal decomposition characteristics and volatile product release behavior during the co-pyrolysis of oily sludge and rice husks using thermogravimetric-infrared (TG-IR) analysis, and to optimize their synergistic pyrolysis performance. The research focused on typical industrial waste (oily sludge) and agricultural waste (rice husks), using different mixing ratios for co-pyrolysis experiments. TG was used to record mass loss curves, while IR was employed to detect functional group changes in the released gases, enabling analysis of synergistic effects and gas composition features. The results showed that co-pyrolysis significantly reduced the initial pyrolysis temperature and enhanced the release efficiency of volatile products, with major products including CO₂, CO, CH₄, and oxygen-containing organics. The optimal blend ratio exhibited a pronounced synergistic effect. The study demonstrated that TG-IR is an effective tool for revealing the pyrolysis mechanisms of mixed waste and provides a scientific basis for resource utilization and pollution control.

Xu, G Y. et al. International Journal of Hydrogen Energy, 2022.

Figure 1. The Contour and Response Surface Diagrams.

FAQ

Q1: Is there a Difference between TG-IR and TG-FTIR?

A1: TG-IR generally refers to thermogravimetric analysis (TG) coupled with a conventional infrared spectrometer, while TG-FTIR specifically refers to coupling with a Fourier-transform infrared spectrometer (FTIR). The two differ slightly in spectral resolution, signal-to-noise ratio, and data processing methods, with FTIR offering higher spectral resolution and analytical performance.

Q2: Can TG-IR Provide Quantitative Data?

A2: This technique is primarily used for qualitative or semi-quantitative analysis. The intensity of infrared absorption peaks can be used to estimate relative concentrations, but for accurate quantification, it is typically necessary to combine TG-IR with other techniques (such as GC or MS) or apply standard curve calibration.

How to order?