Thermogravimetric Analysis (TGA) Service

- Quantifying thermal decomposition temperatures and weight-loss behavior

- Evaluating material composition and optimizing formulations

- Precisely determining moisture, volatiles, fillers, and ash content

- Characterizing thermal reactivity under different atmospheres (e.g., air, nitrogen, oxygen)

Thermogravimetric analysis (TGA) is a high-precision thermal analytical technique used to measure the mass changes of a material under controlled temperature conditions. By heating a sample across a predefined temperature range and recording mass loss as a function of temperature or time, TGA provides critical insights into thermal stability, decomposition behavior, adsorption/desorption processes, and residual content.

Thermogravimetric analysis (TGA) is particularly effective for:

Thanks to its sensitivity, reliability, and broad applicability, TGA is widely used across polymer science, pharmaceutical R&D, inorganic materials, coatings, catalysts, and energy materials research. MtoZ Biolabs offers high-quality Thermogravimetric Analysis (TGA) Service supported by a robust analytical platform and standardized workflows, enabling research and industrial clients to accurately understand the thermal behavior of their materials.

Services at MtoZ Biolabs

MtoZ Biolabs delivers a comprehensive Thermogravimetric Analysis (TGA) Service that covers everything from sample intake and experimental design to data interpretation. Our capabilities include multiple atmospheric conditions (nitrogen, air, oxygen) and heating modes (programmed ramp or isothermal hold) for high-sensitivity monitoring of mass loss.

1. Sample preparation and weighing: Homogenization, drying, and accurate mass measurement tailored to physical characteristics.

2. Heating program setup: Customizable ramp rates and target temperatures (up to 1000 °C).

3. Mass variation recording: Real-time mass loss profiling as a function of temperature/time.

4. Multistep decomposition modeling: Identifies stages via plateau and slope changes.

5. Data analysis and reporting: Includes TG/DTG plots and interpretation of key parameters.

Advanced options such as TGA-MS (TGA coupled with mass spectrometry) and TGA-FTIR (TGA coupled with Fourier-transform infrared spectroscopy) are also available for evolved gas analysis.

Why Choose MtoZ Biolabs?

With a cutting-edge thermal analysis platform and a team of experienced analysts, MtoZ Biolabs offers significant advantages in Thermogravimetric Analysis (TGA) Service:

✅ Stable instrument performance: suitable for a wide variety of materials and programmable ramp/atmosphere switching.

✅ High sample compatibility: Supports powders, films, liquids, and composites.

✅ Customizable protocols: Tailored heating rates, atmospheres, and endpoints to suit specific research goals.

✅ Expert interpretation: Detailed curve analysis and decomposition profiling, ideal for publications and product evaluations.

✅ One-time-charge: Our pricing is transparent, no hidden fees or additional costs.

Applications

Thermogravimetric Analysis (TGA) Service is valuable in numerous scientific and industrial fields:

· Materials science: Assessing thermal stability and degradation of polymers, composites, and fibers.

· Pharmaceutical formulation: Determining thermal properties and moisture content of APIs and excipients.

· Inorganics and ceramics: Analyzing sintering behavior, residuals, and composition.

· Catalysts and adsorbents: Evaluating carrier mass loss and gas desorption behavior.

· Agrochemicals: Measuring volatile components and degradation pathways in pesticides and fertilizers.

· Food and additives: Analyzing moisture, thermal resistance, and bioactive content.

Case Study

Case 1: TGA-based Pyrolysis Kinetics of Lignocellulosic Biomass for Bioenergy Research

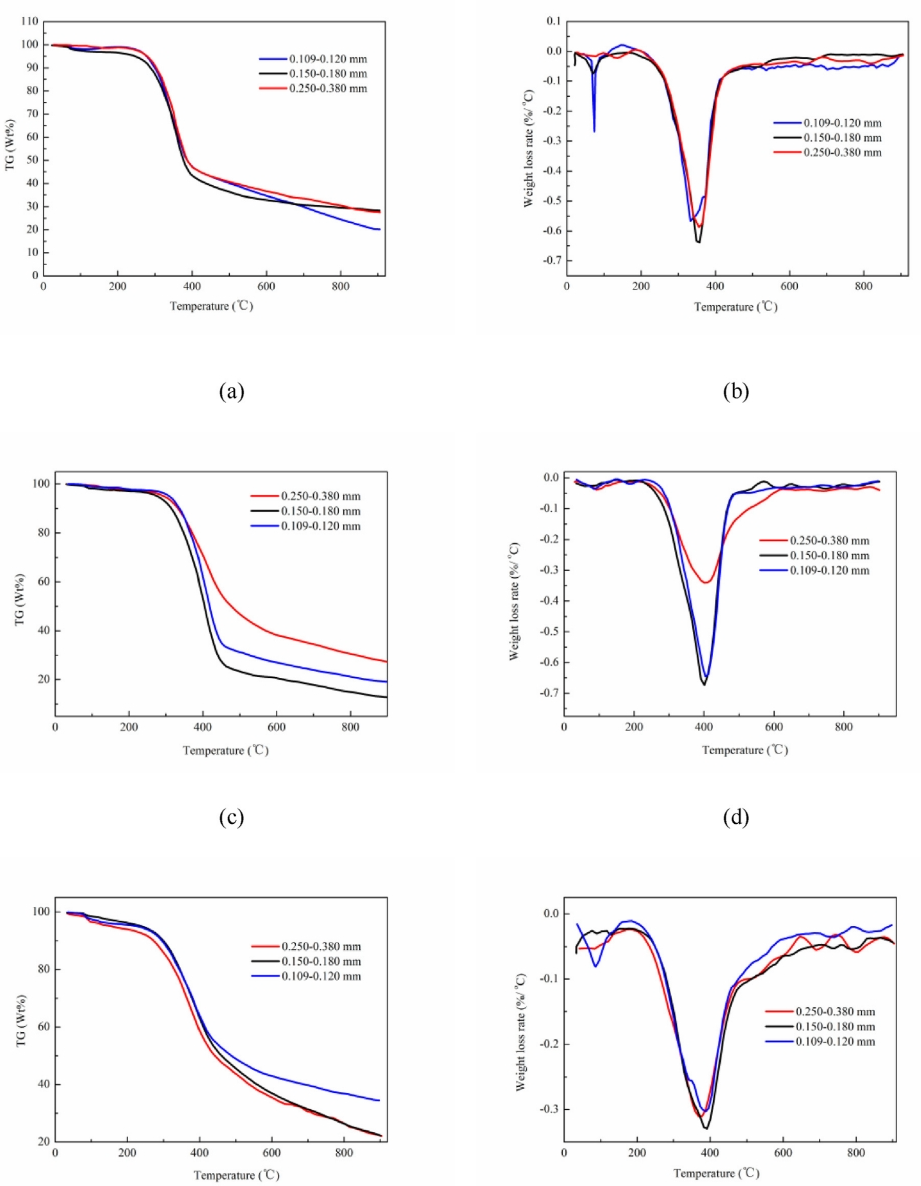

A study examining the pyrolysis behavior of rice straw, pine sawdust, and Phoenix tree leaves employed thermogravimetric analysis (TGA) to characterize thermal degradation and derive kinetic models. Biomass particle size and heating rate were found to significantly affect the onset and peak weight-loss temperatures. Additionally, ash removal and potassium ion addition modulated thermal reactivity. Using Coats–Redfern, Doyle, and Distributed Activation Energy Model (DAEM) methods, the researchers determined apparent activation energy differences across materials. This case highlights the utility of TGA in biomass fuel development and kinetic modeling.

Xiao, R. et al. Energy. 2020.

FAQ

Q1: What types of decomposition mechanisms can TGA analyze?

TGA can assess multistep thermal events such as water evaporation, structural relaxation, additive volatilization, polymer breakdown, and residue formation. With precise mass loss tracking, it supports decomposition sequence evaluation and stability threshold definition, aiding in formulation and performance optimization.

Q2: Can TGA identify unknown components in a material?

Yes. When combined with FTIR or MS, thermogravimetric analysis (TGA) enables evolved gas analysis to identify additives, fillers, or byproducts—providing crucial information for formulation deconstruction and failure analysis.

Q3: Is Thermogravimetric Analysis (TGA) Service suitable for moist or heat-sensitive samples?

Absolutely. Our systems include isothermal and ramp modes, along with pre-drying capabilities. These allow controlled evaluation of sensitive materials, preventing sudden decomposition and improving data resolution and signal-to-noise ratios.

MtoZ Biolabs is committed to delivering efficient, accurate, and customized Thermogravimetric Analysis (TGA) Service to support your research and development needs. Contact us to discuss your project and receive expert technical guidance and tailored service solutions.

How to order?