Temperature Programmed Analytical (TPD/TPR/TPO) Service

- Catalyst Development: Assessing the reducibility and oxidation states of catalytic materials to optimize performance in chemical reactions.

- Environmental Science: Studying adsorption and desorption behaviors of pollutants on materials for environmental remediation strategies.

- Energy Storage: Investigating electrode materials in batteries and fuel cells to understand redox processes and improve efficiency.

- Materials Science: Characterizing surface properties and thermal stability of novel materials for advanced technological applications.

Temperature programmed analysis (TPD/TPR/TPO) provide detailed insights into surface properties, redox behavior, and catalytic activity of materials. Temperature programmed analysis (TPD/TPR/TPO) is essential for characterizing catalysts, adsorbents, and other functional materials, enabling researchers and engineers to tailor material properties for specific applications. MtoZ Biolabs offers high-quality a Temperature Programmed Analytical (TPD/TPR/TPO) Service for accurate and reliable material characterization. Our platform supports a wide range of gas adsorption and desorption analyses, including NH₃, H₂, CO, CO₂, and O₂, to evaluate acid-base properties, reduction-oxidation behavior, and reaction mechanisms under application-relevant conditions.

Understanding the thermal behavior of materials is crucial for optimizing their performance in various applications. The Temperature Programmed Analytical (TPD/TPR/TPO) Service encompasses a set of techniques where a material's response to a controlled temperature change is monitored to study its physical and chemical properties. The primary methods include:

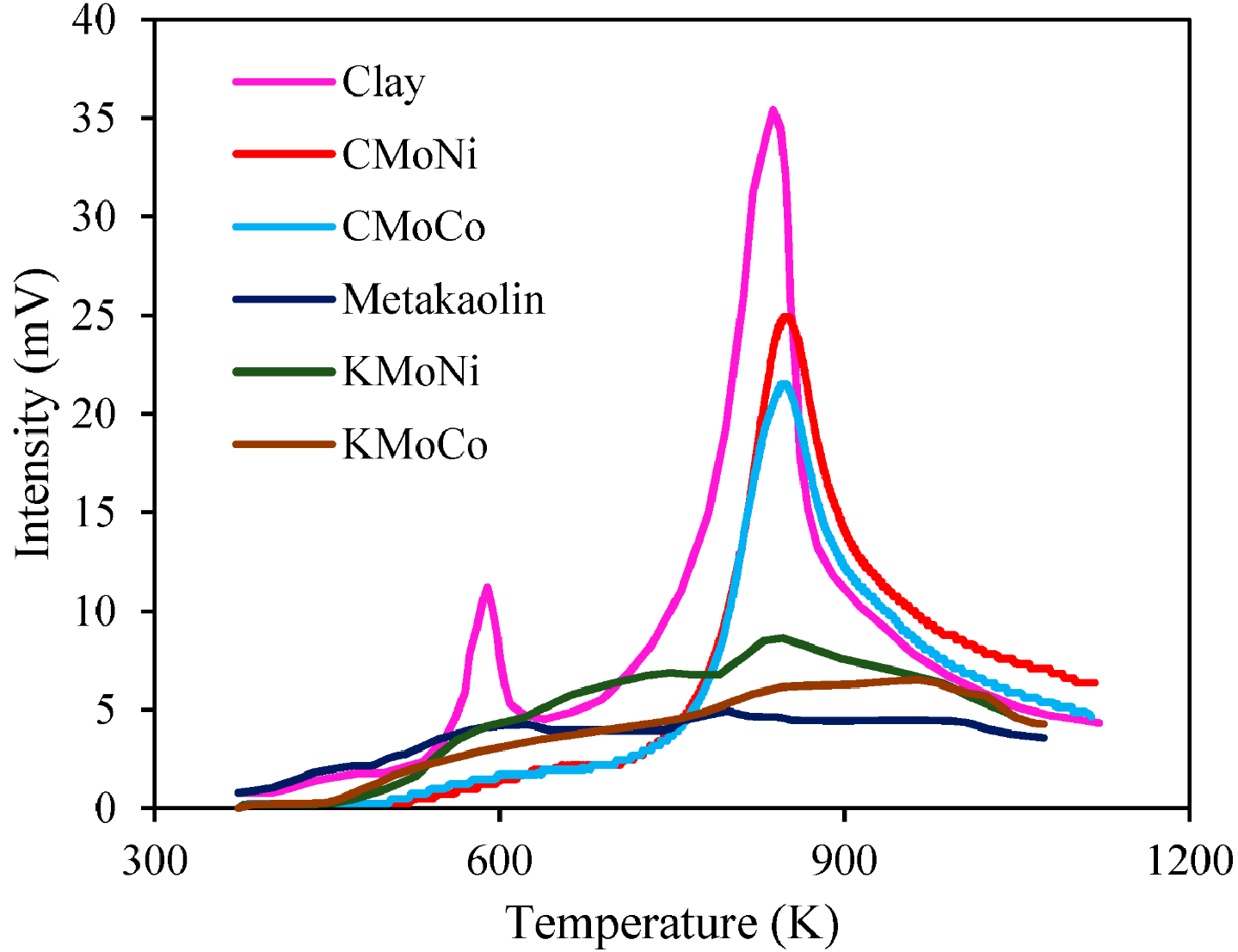

💠Temperature-Programmed Desorption (TPD)

Examines the desorption of adsorbed species from a material's surface as temperature increases, revealing information about adsorption energies and surface interactions.

Figure 1. Temperature Programmed Desorption (TPD) Profiles of NH3 Desorption for Clay, Metakaolin, and the Functionalized Samples

💠Temperature-Programmed Reduction (TPR)

Investigates the reduction behavior of metal oxides or supported catalysts by monitoring the consumption of a reducing gas (e.g., hydrogen) as the temperature rises, providing insights into reducibility and metal-support interactions.

Figure 2. Temperature-Programmed Reduction (TPR) Profiles of La₂ − ₓCeₓCoO₄±ᵧ Catalysts

💠Temperature-Programmed Oxidation (TPO)

Studies the oxidation processes of materials by observing the uptake of an oxidizing gas (e.g., oxygen) during controlled heating, useful for understanding oxidation states and stability.

Ibrahim, A. et al. Energy Sci Eng. 2023.

Figure 3. Temperature‐Programmed Oxidation (TPO) of Catalysts Obtained after 7.5 h Reaction at 700°C

Analysis Workflow

1. Sample Preparation

Samples are prepared to ensure cleanliness and appropriate physical form, such as powders or pellets, to facilitate uniform gas flow and heat transfer.

2. Pretreatment

Depending on the analysis type, samples may undergo pretreatment steps like oxidation, reduction, or degassing to establish a defined starting state.

3. Temperature Programming

The sample is subjected to a controlled temperature ramp at a specified rate while being exposed to the relevant gas (inert, reducing, or oxidizing).

4. Gas Flow and Detection

Gases desorbed or consumed during the temperature ramp are monitored using detectors such as TCDs or mass spectrometers to capture real-time data.

5. Data Analysis

The collected data are analyzed to identify characteristic peaks corresponding to desorption, reduction, or oxidation events, providing insights into material properties and behaviors.

Service Advantages

✔️High sensitivity for gas detection and signal resolution

✔️Tailored protocols for different material types

✔️Fast turnaround with reliable data quality

✔️Experienced analysts ensure accurate interpretation

✔️Secure data handling and strict confidentiality

✔️Compatible with diverse research and industrial applications

Applications

The Temperature Programmed Analytical (TPD/TPR/TPO) Service is widely applied in various fields, including:

FAQ

Q1: What types of materials are suitable for the Temperature Programmed Analytical (TPD/TPR/TPO) Service?

These techniques are ideal for catalysts, metal oxides, adsorbents, and other porous or functional materials.

Q2: What are the limitations of TCD detectors in TPO analyses?

Thermal conductivity detectors (TCDs) may lack sensitivity for trace oxygen consumption (<1% concentration changes). For low-concentration oxidative reactions (e.g., coke combustion in catalysts), mass spectrometry (MS) is preferred due to its ppm-level detection limits. TCDs are ideal for high-concentration O₂/CO₂ monitoring.

Temperature-programmed analytical techniques such as TPD, TPR, and TPO have become indispensable tools for probing surface chemistry, redox behavior, and thermal reactivity of functional materials. MtoZ Biolabs delivers high-quality, customizable Temperature Programmed Analytical (TPD/TPR/TPO) Services. From experimental design to data interpretation, we support your goals with reliable results, rapid turnaround, and full analytical transparency. Contact us today to discuss your project requirements.

How to order?