Mercury Intrusion Porosimetry (MIP) Testing Service

Mercury intrusion porosimetry (MIP) is a vital technique for analyzing the pore structure of porous materials. By applying external pressure to force liquid mercury into the pores and recording the volume changes at various pressures, this method enables the quantitative evaluation of pore size distribution, specific pore volume, surface area, and porosity. MIP covers a wide pore size range (from 3 nm to several hundred microns), offers high throughput, and is applicable to a diverse range of materials.

MtoZ Biolabs provides standardized Mercury Intrusion Porosimetry (MIP) Testing Service that encompasses the entire workflow from sample preparation to data interpretation. Our service supports both researchers and engineering teams in understanding microstructural characteristics and optimizing material performance and processing strategies.

Technical Principles

The core principle of mercury intrusion porosimetry (MIP) testing lies in the interaction between fluid and solid interfaces and their pressure-volume response. Mercury, a non-wetting liquid, penetrates the pore structure only under externally applied pressure, overcoming capillary resistance. The critical pressure required for intrusion is inversely related to pore size. By incrementally increasing the pressure and monitoring the mercury intrusion volume, pore size distribution can be calculated using physical models such as the Washburn equation, revealing hierarchical pore structure features.

Compared with gas adsorption methods (e.g., BET) or other techniques, mercury intrusion porosimetry (MIP) testing offers several advantages in analyzing complex porous systems:

✅ Wide pore size coverage: Capable of characterizing micropores to macropores continuously.

✅ High sensitivity: Suitable for sub-micron pores and trace porosity quantification.

✅ Material versatility: Compatible with powders, bulk solids, membranes, and various sample morphologies.

Analysis Workflow

The Mercury Intrusion Porosimetry (MIP) Testing Service at MtoZ Biolabs follows rigorous standardized procedures to ensure high data reproducibility:

1. Sample pretreatment: Select drying methods based on material properties to remove surface-adsorbed substances or volatiles.

2. Instrument calibration: Use reference materials to verify accuracy of pressure and volume measurement systems.

3. Mercury intrusion test: Conduct pore filling and extrusion under controlled pressure in an inert gas environment.

4. Data analysis: Generate pore size distribution curves, cumulative pore volume plots, and fractal dimension analysis using proprietary software.

5. Report delivery: Provide comprehensive technical reports including data interpretation, graphical visualization, and actionable insights.

Why Choose MtoZ Biolabs?

✔ Advanced analysis platform: Equipped with Micromeritics AutoPore systems featuring high-sensitivity pressure sensors and volumetric detection modules.

✔ Customized testing protocols: Tailored methods for nano-materials, biocomposites, and unconventional porous systems.

✔ Integrated support: Our cross-disciplinary team combines SEM, XRD, BET, and MIP data to deliver multi-scale structure-property correlation analysis.

✔ One-time-charge: Our pricing is transparent, no hidden fees or additional costs.

Applications

Mercury Intrusion Porosimetry (MIP) Testing Service is widely used in material R&D, quality control, and performance correlation studies across fields such as:

· Construction and civil materials: Assess permeability and durability of concrete, bricks, gypsum, etc.

· Energy and battery materials: Characterize pore structure of porous electrodes, separators, and supports.

· Catalysts and adsorbents: Evaluate surface area and pore size impacts on catalytic performance.

· Pharmaceutical and controlled-release materials: Investigate how carrier pore structure affects drug release profiles.

· Ceramics and membranes: Correlate pore structure with filtration properties and mechanical strength.

· Geological and core analysis: Determine porosity and pore networks in reservoir rocks for oil and gas exploration.

Case Study

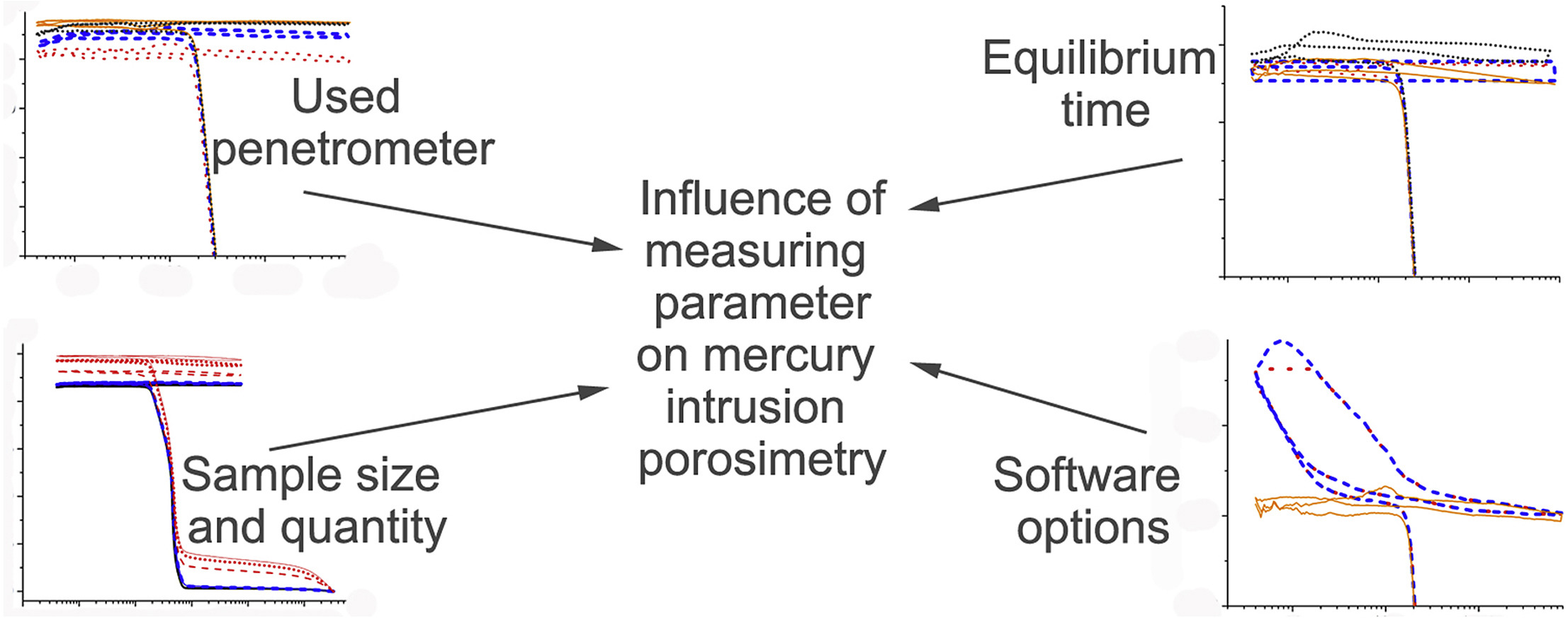

Case 1: Enhancing Pore Structure Characterization via Optimized MIP Parameters

Researchers applied Mercury Intrusion/Extrusion Porosimetry to study the pore structure of Al₂O₃–C composites, evaluating the impact of various test parameters (e.g., stem and bulb volume of the penetrometer, equilibrium time, sample mass and size, data processing strategies) on measured pore size distribution, porosity, total pore volume, and apparent density. Results demonstrated that these parameters significantly influence both intrusion and extrusion behavior. In cyclic tests, parameter fluctuations may introduce errors that affect the accuracy of structural quantification.

Voigt, C. et al. Microporous Mesoporous Mater. 2020.

MtoZ Biolabs offers professional Mercury Intrusion Porosimetry (MIP) Testing Service supported by flexible testing configurations and high-resolution instruments to meet your needs for advanced pore characterization.

FAQ

Q1: How does MIP compare to other porosity analysis techniques such as BET or SEM?

MIP provides direct pore size measurements across a broader range than BET, which is limited to mesoporous range (2–50 nm). While SEM offers morphological visualization, it lacks statistical and volumetric accuracy. MtoZ Biolabs integrates MIP, BET, and SEM to deliver multidimensional porosity characterization.

Q2: Can high-pressure mercury intrusion damage delicate samples?

Yes, some brittle or porous materials may undergo compaction under high pressure. MtoZ Biolabs evaluates structural resilience prior to testing and selects optimal pressure limits to balance data accuracy with sample integrity.

Q3: Can mercury-sensitive materials (e.g., polymers) be analyzed?

Since MIP uses mercury as the probing fluid, reactive components (e.g., sulfides) must be disclosed. MtoZ Biolabs provides protective atmospheres and low-toxicity substitute fluids when applicable and optimizes pretreatment protocols to minimize reactivity.

Q4: Can mercury access closed or complex pore networks?

Mercury only intrudes accessible pores connected to the external surface. Closed pores remain undetected. MtoZ Biolabs recommends complementary imaging (e.g., X-ray CT) for evaluating isolated pore systems.

MtoZ Biolabs offers not only Mercury Intrusion Porosimetry (MIP) Testing Service but also full-spectrum structural analysis solutions powered by a cross-functional technical team. We deliver customized methods for challenging systems (e.g., nano-porous or biological composites) and integrate SEM, XRD, and other technologies for data-rich structure-function mapping. Contact us to unlock comprehensive insights from your materials.

How to order?