Laser Thermal Conductivity Testing Service

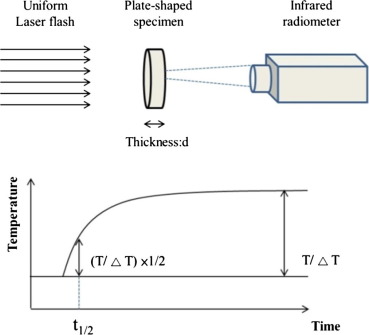

Laser thermal conductivity testing is an analytical technique based on the laser flash method (LFA), primarily used to measure the thermal diffusivity and thermal conductivity of solid materials within a specific temperature range. In this method, a laser pulse is used to instantaneously heat one side of the sample, and the heat propagation through the material is recorded. By combining parameters such as sample thickness, thermal diffusivity, and specific heat capacity, the thermal conductivity of the material can be calculated. This method offers advantages such as non-contact measurement, rapid data acquisition, and high precision.

Laser thermal conductivity testing service is widely applied in the analysis of electronic packaging materials, ceramics, metals, composites, thermal interfacematerials (TIMs), thermal insulation coatings, and polymers. It is especially valuable in research involving thermal management, energy-efficient materials development, thermal barrier system design, and evaluation of thermal stability. Laser thermal conductivity testing has become a critical tool in both material thermal property research and industrial quality control.

Zhang, P J. et al. Journal of Thermal Science, 2024.

Figure 1. Principle of Thermal Diffusivity Measurement by the Laser Flash Method.

Services at MtoZ Biolabs

Based on a high-performance laser flash analysis platform, MtoZ Biolabs’ laser thermal conductivity testing service provides precise measurement of thermal diffusivity for various materials (e.g. ceramics, metals, and polymers) with a standard diameter of 12.7 ± 0.1 mm, across a temperature range from room temperature up to 750°C. By combining the measured thermal diffusivity with known sample density and specific heat capacity, the thermal conductivity is accurately calculated. This service adopts a non-contact testing approach, ensuring fast, repeatable, and highly accurate data, making it ideal for thermal property evaluation in both scientific research and engineering applications.

Analysis Workflow

1. Sample Preparation

The test material is machined into discs or bulk specimens of specified dimensions, ensuring a flat, clean surface. Graphite coating may be applied as needed to improve energy absorption and minimize reflection errors.

2. Thermal Diffusivity Measurement

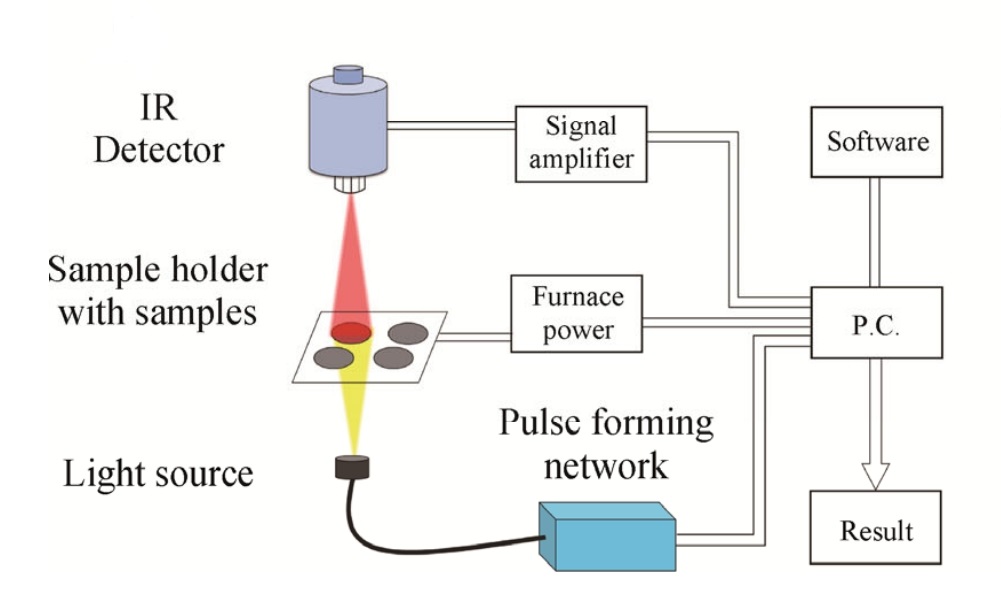

The specimen is placed in the laser flash analyzer under vacuum or controlled atmosphere. A short-pulse laser heats one side of the sample, while an infrared detector records the temperature rise on the opposite side to determine thermal diffusivity.

3. Specific Heat and Density Determination

Based on the material type, specific heat capacity is measured using standard thermal analysis methods (e.g., DSC), and density is determined through volume and mass measurements.

4. Thermal Conductivity Calculation

Thermal conductivity is calculated by combining the measured thermal diffusivity, specific heat, and density values using the appropriate formula.

5. Data Analysis and Report Output

Thermal conductivity trends across various temperatures are analyzed, and a comprehensive test report is provided, including thermal diffusivity curves, conductivity data, and application recommendations.

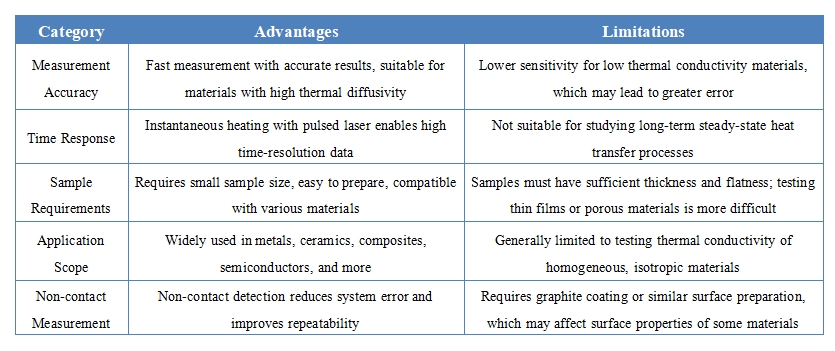

Advantages and Limitations

Applications

1. Thermal Management of Electronic and Semiconductor Devices

Laser thermal conductivity testing service can be used to evaluate the thermal performance of chip packaging materials, thermal greases, and thermal interface materials (TIMs), helping optimize heat dissipation designs.

2. New Material Development and Performance Screening

This technique enables thermal property characterization of metals, ceramics, and polymer composites during the R&D phase, aiding in material selection and formulation optimization.

3. Energy Materials Research

Laser thermal conductivity testing service is applicable to thermoelectric materials, battery separators, electrode materials, and more, assessing their thermal transport behavior and energy conversion efficiency.

4. Automotive Industry

By analyzing the thermal conductivity of structural components and insulation materials, the service ensures thermal stability and safety under high-temperature or extreme operating conditions.

5. Academic Research and Standard Validation

Laser thermal conductivity testing service provides authoritative thermal conductivity data to support scientific research projects and the establishment of standards for new materials.

Case Study

1. Rapid Thermal Conductivity Measurement of Porous Thermal Insulation Material by Laser Flash Method

This study aims to evaluate the feasibility and accuracy of using the laser flash method (LFA) for rapid thermal conductivity measurement of porous thermal insulation materials. The research focused on representative porous insulation samples. The method involves applying a short laser pulse to heat the sample surface, measuring the rear-face temperature rise to calculate thermal diffusivity, and then combining this with specific heat and density to determine thermal conductivity. Results indicate that LFA offers good measurement stability and reproducibility for porous materials in the medium-to-high temperature range. It also provides fast testing speed and requires only small sample volumes, making it suitable for insulation materials with varying thicknesses and pore structures. The study concludes that LFA is an efficient, non-destructive method for thermal conductivity measurement, particularly well-suited for rapid screening and evaluation of porous insulation materials, with broad application potential in building materials, energy systems, and aerospace engineering.

Lian, T W. et al. Advanced Powder Technology, 2016.

Figure 2. The Principle and Temperature Rise Curve of Laser Flash Method.

FAQ

Q1: What Is the Basic Principle of Laser Thermal Conductivity Testing?

A1: Based on the laser flash method (LFA), the sample is irradiated on one side with a short laser pulse, and the temperature rise on the opposite side is recorded. This allows for the calculation of thermal diffusivity, which, combined with specific heat capacity and density, yields the thermal conductivity.

Q2: What Is the Temperature Range for Testing?

A2: The test supports thermal conductivity measurements from room temperature up to 750°C, suitable for materials with good thermal stability.

How to order?