Fmoc Solid Phase Peptide Synthesis Service

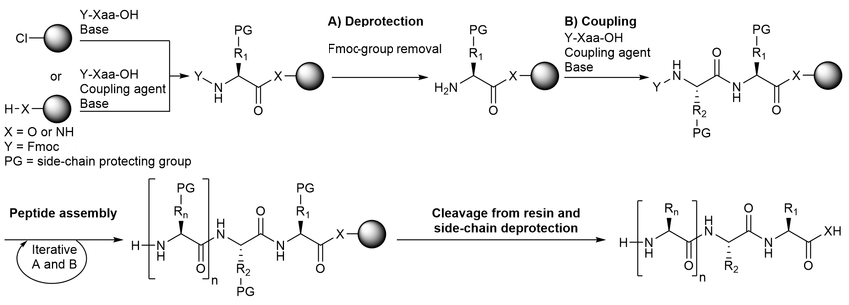

Fmoc Solid Phase Peptide Synthesis Service is based on solid support synthesis of peptides by sequentially coupling amino acids in a specific order to synthesize peptides with defined sequences and controllable structures. Unlike traditional solution-phase synthesis, Fmoc Solid Phase Peptide Synthesis (Fmoc-SPPS) uses solid-phase resin to immobilize the peptide chain, making the separation and washing of reactants more efficient.

Before each amino acid addition, the Fmoc group protects its α-amino group, preventing nonspecific reactions. After deprotection using piperidine solution to expose the active amino group, coupling reagents facilitate the formation of peptide bonds between the amino and carboxyl groups, ensuring specificity at every step. Finally, the synthesized peptide is cleaved from the resin using trifluoroacetic acid (TFA), which also removes side-chain protecting groups, yielding the target peptide. The process of Fmoc-SPPS minimizes side reactions and supports the introduction of complex functional modifications such as fluorescent labeling, phosphorylation, or cyclization.

With extensive experience in peptide synthesis and advanced experimental platforms, MtoZ Biolabs offers Fmoc Solid Phase Peptide Synthesis Service for synthesizing short peptides, modified peptides, cyclic peptides, and other complex peptide molecules.

Analysis Workflow

General workflow for Fmoc Solid Phase Peptide Synthesis Service:

Bédard F. et al. Frontiers in Microbiology. 2018.

1. Resin Preparation

Select the appropriate resin based on the target peptide sequence, and perform swelling and activation.

2. Amino Acid Coupling

Mix Fmoc-protected amino acids with an activator and add them to the resin to form peptide bonds.

3. Fmoc Deprotection

Use piperidine solution to remove the Fmoc group, exposing the free amine for subsequent coupling.

4. Repeated Coupling and Deprotection

Repeat the coupling and deprotection steps according to the sequence to extend the peptide chain step by step.

5. Peptide Cleavage and Deprotection

Use a strong acidic reagent (e.g., TFA) to cleave the peptide from the resin and simultaneously remove side-chain protecting groups.

6. Purification and Validation

Purify the target peptide using high-performance liquid chromatography (HPLC) and verify its molecular weight with mass spectrometry to ensure successful synthesis.

Applications

Common applications of Fmoc Solid Phase Peptide Synthesis are as follows:

Drug Development

Synthesis of antimicrobial peptides, antitumor peptides, hormone peptides, antiviral peptides, and more to support the development of novel drugs.

Structure and Function Studies

Preparation of modified peptides, cyclic peptides, or functional peptide fragments for research into protein structure and functional mechanisms.

Biomarker Development

Synthesis of biomarker peptide fragments for early disease detection or immunodiagnostics.

Vaccine Research

Production of antigen peptides for vaccine design, immune response analysis, or antibody generation.

FAQ

Q. How to Avoid Low Yield and Side Reactions in Long Peptide (>30 Amino Acids) Synthesis?

Synthesizing long peptides presents challenges such as decreased coupling efficiency, accumulation of side reactions, and peptide chain aggregation hindering elongation. The following strategies can effectively improve the success rate and yield of long peptide synthesis:

1. Optimize Coupling Efficiency

Use high-efficiency coupling agents: Employ reagents such as HATU to significantly enhance coupling efficiency and reduce the likelihood of side reactions.

Extend coupling time: Allow longer reaction times for each amino acid coupling step to ensure reaction completion.

Double coupling strategy: Perform double coupling for each amino acid to further minimize the risk of incomplete coupling.

2. Use Cosolvents to Reduce Aggregation

During long peptide synthesis, intra-chain hydrogen bonding can lead to peptide chain aggregation. Adding cosolvents like dimethyl sulfoxide (DMSO) can disrupt aggregation structures, improving elongation efficiency.

3. Select Appropriate Resin

Use low-loading resins (e.g., 0.2–0.4 mmol/g) to reduce peptide chain density, mitigating inter-chain interactions and aggregation risks.

4. Stepwise Cleavage Strategy

Side-chain protecting groups on long peptides may lead to complex byproducts during final cleavage. A stepwise cleavage strategy, removing protecting groups in phases, can minimize side reactions.

5. Strictly Control Reaction Conditions

Regularly monitor the completion of coupling and deprotection steps to ensure each reaction is carried out efficiently.

6. Fragment Assembly Approach

For ultra-long peptides, employ a peptide fragment condensation strategy, chemically joining shorter fragments to form the full-length peptide chain.

Case Study

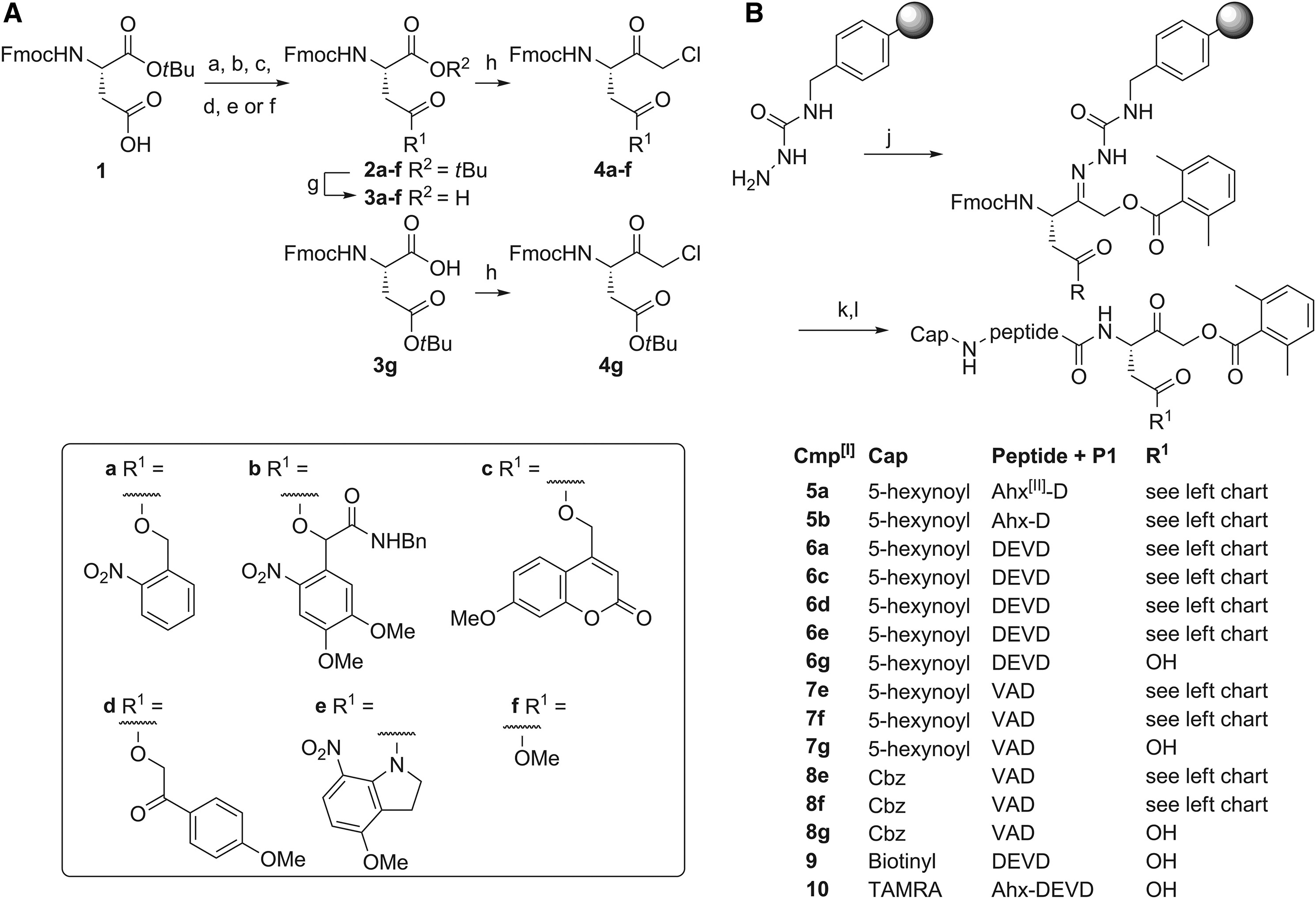

This study successfully synthesized a light-controlled Caspase inhibitory peptide using Fmoc solid phase peptide synthesis technology, providing a novel research tool for precise regulation of apoptosis.

Chakrabarty S. et al. Cell Chemical Biology. 2020.

MtoZ Biolabs, an integrated chromatography and mass spectrometry (MS) services provider.

Related Services

Verification Service of Synthetic Peptide Sequence

How to order?